Preparation method of surface print adsorbent of yeast template hollow silica-based material for adsorbing and separating strontium ions and application thereof

A silicon-based material, surface imprinting technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., to achieve good mechanical properties and thermal stability, avoid incomplete elution, and high mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

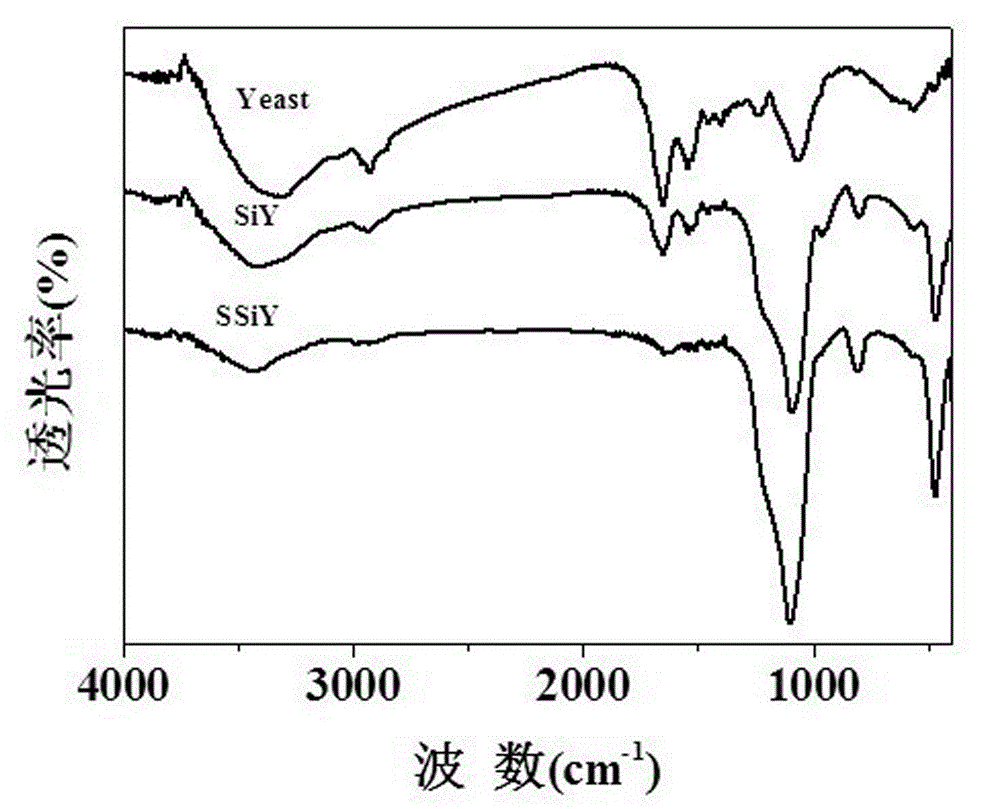

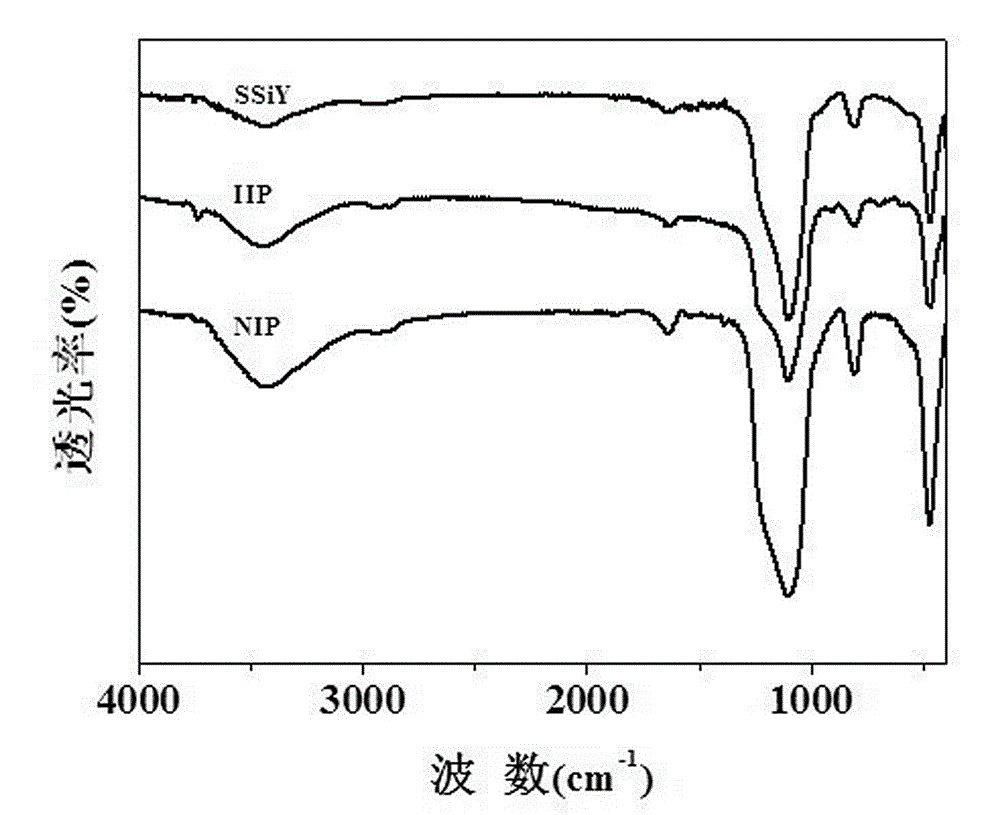

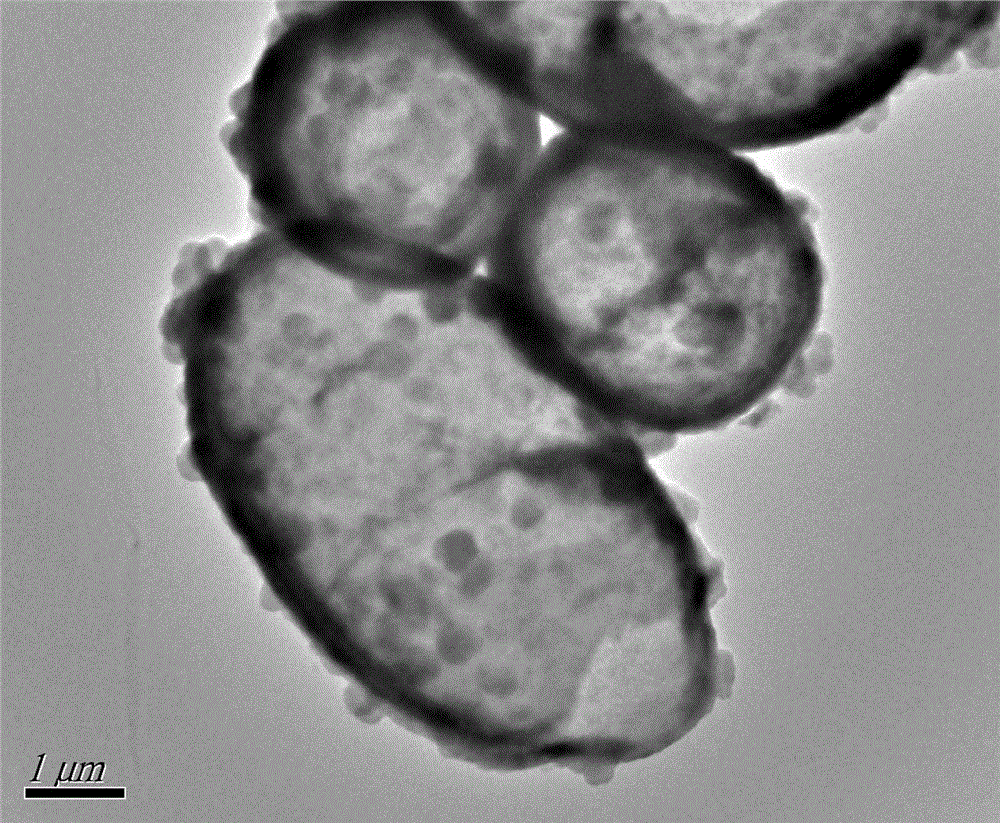

[0042] (1) Preparation of yeast / silicon complex (SiY)

[0043] The modified Stäber method was used to directly coat silica on the surface of yeast cells to prepare yeast / silicon composite materials. The specific preparation process was as follows: 15 g of dry yeast was weighed and dissolved in 60 mL of 0.9% NaCl solution 4.0 mL of yeast suspension was pipetted, 4.0 mL of deionized water was added, and stirred rapidly for 10 min; 16 mL of absolute ethanol was added, and the mixture was sonicated for 20 min to make the cells uniform Disperse; add 0.75 mL concentrated ammonia water and 2.0 mL tetraethyl orthosilicate (TEOS), and age for 5.0 h with magnetic stirring at room temperature; collect the product by filtration, wash the product three times with deionized water, and fully dry it at room temperature The product is fully ground with a mortar, passed through a 100-mesh sieve, and set aside.

[0044] (2) Preparation of yeast template hollow silicon-based material (SSiY)

[...

Embodiment 2

[0050] (1) Preparation of yeast / silicon complex (SiY)

[0051] The modified Stäber method was used to directly coat silica on the surface of yeast cells to prepare yeast / silicon composite materials. The specific preparation process was as follows: 15 g of dry yeast was weighed and dissolved in 55 mL of 0.8% NaCl solution 3.5 mL of yeast suspension was pipetted, 3.5 mL of deionized water was added, and stirred rapidly for 8 min; 14 mL of absolute ethanol was added, and the mixture was sonicated for 15 min to make the cells uniform Disperse; add 0.65 mL of concentrated ammonia water and 1.5 mL of tetraethyl orthosilicate (TEOS), and age for 5.0 h with magnetic stirring at room temperature; collect the product by filtration, wash the product with deionized water three times, and fully dry it at room temperature The product is fully ground with a mortar, passed through a 100-mesh sieve, and set aside.

[0052] (2) Preparation of yeast template hollow silicon-based material (SSiY)...

Embodiment 3

[0058] (1) Preparation of yeast / silicon complex (SiY)

[0059] The modified Stäber method was used to directly coat silica on the surface of yeast cells to prepare yeast / silicon composite materials. The specific preparation process was as follows: 15 g of dry yeast was weighed and dissolved in 65 mL of 1.0% NaCl solution 4.5 mL of yeast suspension was obtained by pipetting 4.5 mL of yeast suspension, adding 4.5 mL of deionized water, and stirring rapidly for 12 min; adding 18 mL of absolute ethanol, and ultrasonicating the mixture for 25 min to make the cells uniform Disperse; add 0.75 mL of concentrated ammonia water and 2.0 mL of tetraethyl orthosilicate (TEOS), and age for 6.0 h with magnetic stirring at room temperature; collect the product by filtration, wash the product with deionized water three times, and fully dry it at room temperature The product is fully ground with a mortar, passed through a 100-mesh sieve, and set aside.

[0060] (2) Preparation of yeast templat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com