Method for treating trifluralin pesticide wastewater by diamond film electrode

A technology of diamond film and pesticide wastewater, which is applied in the field of environmental protection technology and electrochemistry, can solve the problems of diamond film electrode treatment that have not yet been seen, and achieve the effects of suitable popularization, wide potential window and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

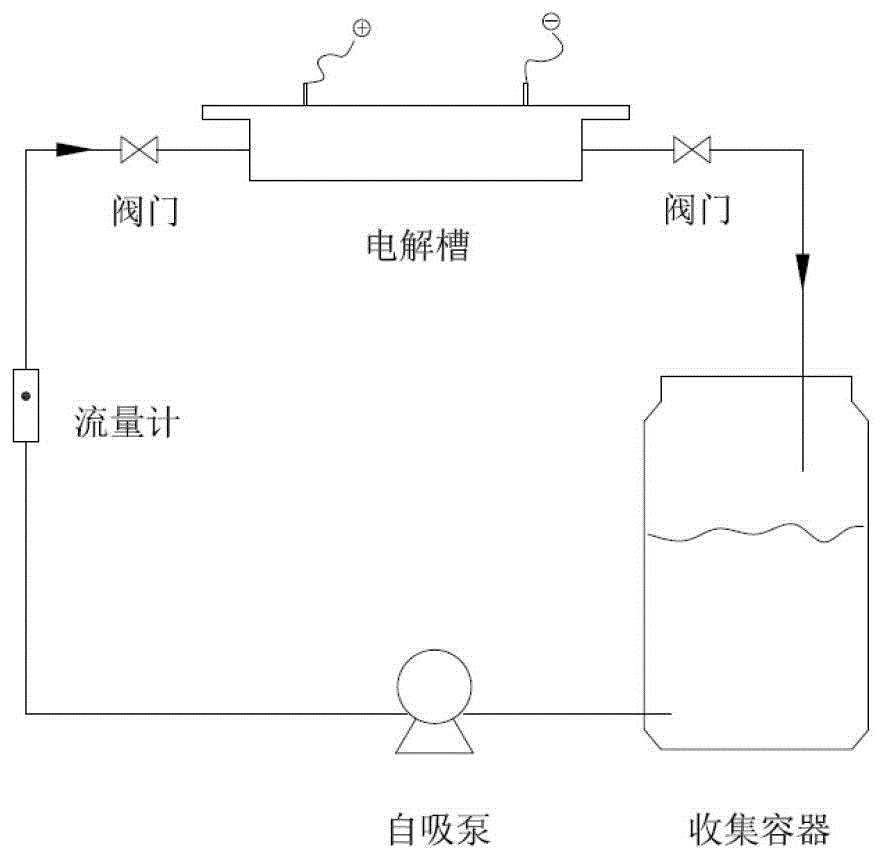

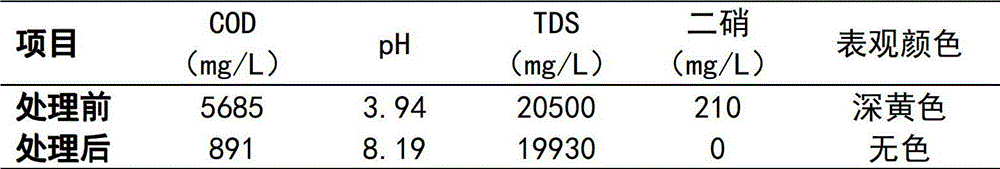

[0028] Pour 25kg of trifluralin waste water into the collection container, turn on the self-priming pump, adjust the valve to control the flow through the electrolytic cell to 0.3t / h, turn on the regulated DC power supply, adjust the voltage to 5V, and continue to treat the waste water for 8 hours. The results are as follows:

[0029]

Embodiment 2

[0031] Pour 25kg of trifluralin wastewater into the collection container, turn on the self-priming pump, adjust the valve to control the flow through the electrolytic cell to 0.3t / h, turn on the regulated DC power supply, adjust the voltage to 7V, and continue to treat the waste for 1 hour. The results are as follows:

[0032]

Embodiment 3

[0034] Pour 25kg of trifluralin waste water into the collection container, turn on the self-priming pump, adjust the valve to control the flow through the electrolytic cell to 2t / h, turn on the regulated DC power supply, adjust the voltage to 7V, and continue to treat the waste for 1 hour. The results are as follows:

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com