Preparation method of raw medicine of environment-friendly iron sucrose

A green and environmentally friendly, iron sucrose technology, applied in the preparation of sugar derivatives, chemical instruments and methods, disaccharides, etc., can solve the problems of wide precipitation area, high production cost, poor specificity, etc., and achieve simple and environmentally friendly process routes, production equipment Simple, effective production process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A preparation method of iron sucrose raw material medicine, has the following steps:

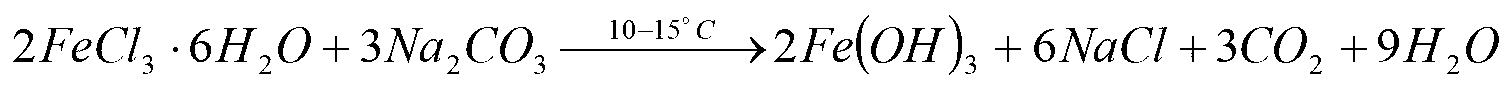

[0018] (1) By weight percentage, FeCl 3 ·6H 2 06Kg, add 300L of purified water, put into the reaction kettle and stir the solution, control the temperature in the kettle to 14°C; 2 CO 3 3.72Kg, dissolved in 60L of pure water, pumped in Na with a peristaltic pump 2 CO 3 to FeCl 3 ·6H 2 In the O solution, the feeding time is 1 hour, and after the feeding is completed, continue to stir for 1 hour and then centrifuge to obtain Fe(OH) 3 Raw clay, Fe(OH) 3 Add 400L of pure water to the original clay, stir and wash for 1 hour, repeat centrifugal washing 4 times to obtain Fe(OH) 3 Clay, weighed 19.6Kg, measured Fe(OH) 3 The content of Fe in the cement is 5.20%;

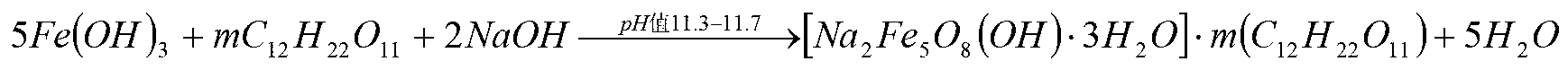

[0019] (2) Weigh 15.0Kg of sucrose and add to Fe(OH) 3 In the cement, stir evenly, adjust the pH to 11.60 with 6M NaOH solution, stir for half an hour, heat to 110°C, react for 10 hours, and cool to room temperature;

[0...

Embodiment 2

[0022] A preparation method of iron sucrose raw material medicine, has the following steps:

[0023] (1) By weight percentage, FeCl 3 ·6H 2 06Kg, add 300L of purified water, drop into the reaction kettle and stir the solution, control the temperature in the kettle to 12°C; 2 CO 3 3.66Kg, dissolved in 60L of pure water, pumped in Na with a peristaltic pump 2 CO 3 to FeCl 3 ·6H 2 In the O solution, the feeding time is 1 hour, and after the feeding is completed, continue to stir for 1 hour and then centrifuge to obtain Fe(OH) 3 Raw clay, Fe(OH) 3 Add 400L of pure water to the original clay, stir and wash for 1 hour, repeat centrifugal washing 4 times to obtain Fe(OH) 3 Clay, weighed 20.4Kg, measured Fe(OH) 3 The content of Fe in the cement is 4.98%;

[0024] (2) Weigh 14.4Kg of sucrose and add to Fe(OH) 3 In the cement, stir evenly, adjust the pH to 11.50 with 6M NaOH solution, stir for half an hour, heat to 110°C, react for 10 hours, and cool to room temperature;

[...

Embodiment 3

[0027] A preparation method of iron sucrose raw material medicine, has the following steps:

[0028] (1) By weight percentage, FeCl 3 ·6H 206Kg, add 300L of purified water, drop into the reaction kettle and stir the solution, control the temperature in the kettle to 10°C; 2 CO 3 3.69Kg, dissolved in 60L of pure water, pumped in Na with a peristaltic pump 2 CO 3 to FeCl 3 ·6H 2 In the O solution, the feeding time is 1 hour, and after the feeding is completed, continue to stir for 1 hour and then centrifuge to obtain Fe(OH) 3 Raw clay, Fe(OH) 3 Add 400L of pure water to the original clay, stir and wash for 1 hour, repeat centrifugal washing 4 times to obtain Fe(OH) 3 Clay, weighed 18.5Kg, measured Fe(OH) 3 The content of Fe in the cement is 5.24%;

[0029] (2) Weigh 14.2Kg of sucrose and add to Fe(OH) 3 In the cement, stir evenly, adjust the pH to 11.70 with 6M NaOH solution, stir for half an hour, heat to 110°C, react for 10 hours, and cool to room temperature;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| distribution coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com