Preparation method of antibacterial hydrophobic complexing agent for polyester fibers

A polyester fiber and compounding agent technology, applied in the preparation of organic compounds, fiber types, fiber treatment, etc., can solve the problems of poor light stability, non-persistent antibacterial effect, environmental pollution, etc., and achieve easy high-temperature processing and good dispersibility. , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

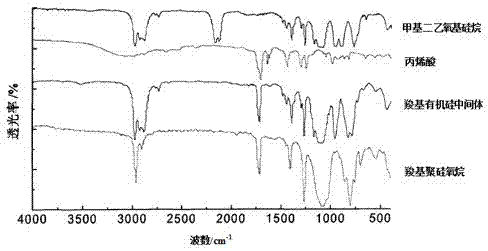

[0033] Embodiment 1: the synthesis of carboxypolysiloxane

[0034] Take 604.125g (4.5mol) of methyldiethoxysilane, 216.18g (3mol) of acrylic acid, and 0.082g of platinum dioxide into a three-neck flask with a stirrer, stir evenly at room temperature, raise the temperature to 85°C, and react for 23h End; suction filtration, vacuum distillation to remove impurities and low boilers, then vacuum dry at 55°C for 24 hours to obtain a carboxyl organosilicon intermediate; take half of the mass of this intermediate and slowly add it dropwise to excess sulfuric acid with a volume fraction of 40% In the solution, the dropping speed is strictly controlled. After the dropping is completed, the reaction is completed at 23°C for 2 hours; repeated washing with distilled water until the pH value of the lotion is 7, suction filtration, and vacuum drying at 55°C for 24 hours to obtain carboxypolysiloxane alkyl;

[0035] Characterization method:

[0036] Fourier Transform Infrared Spectroscopy:...

Embodiment 2

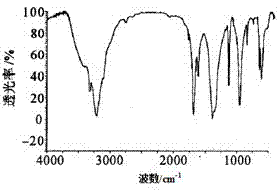

[0046] Embodiment 2: the synthesis of monoguanidine compound

[0047] Take 404.265g (1.5mol) of octadecylamine and 108.09g (1.8mol) of glacial acetic acid in a three-necked flask with a stirrer, mix well and then raise the temperature to 110°C, stir and add 94.5g (water pump) dropwise under air pump ( 2.25mol) cyanamide, maintain the reaction temperature at 110°C; after the dropwise addition, continue the reaction for 30 minutes, stop heating, and cool; add 2 times the volume of water, heat to dissolve, adjust the pH value to about 10 with sodium hydroxide, and let stand After separating the upper layer substance, dissolve it with 2 times the volume of water, heat it in a water bath, prepare an acetic acid solution with a mass fraction of 36% with glacial acetic acid to adjust the pH value of the system to 7, leave it to separate the product, and dry it in vacuum after rotary evaporation; Obtain monoguanidine base compound with ethanol recrystallization;

[0048] Characteriza...

Embodiment 3

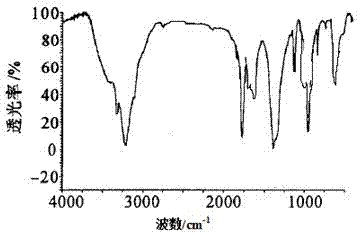

[0054] Embodiment 3: condensation reaction of carboxypolysiloxane and monoguanidine compound

[0055] The carboxyl content of carboxypolysiloxane measured by acid-base titration is 7.60 mmol / g;

[0056] Take 131.58g carboxypolysiloxane, 404.3g (1.3mol) monoguanidine compound, 286.57g (1.69mol) 6-chloro-1-hydroxybenzotriazole (6-Cl-HOBt) In the there-necked flask, add a certain amount of ethyl acetate to dissolve, cool down to 1°C; slowly dropwise add ethyl acetate solution containing 157.86g (1.56mol) of triethylamine (the concentration of triethylamine is 2.5mmol / 10ml), naturally Warming up to room temperature, stirring for 12 hours, filtering, washing with ethyl acetate and evaporating the ethyl acetate under reduced pressure to obtain an antibacterial and hydrophobic composite agent for polyester fibers.

[0057] Characterization method:

[0058] Fourier Transform Infrared Spectroscopy: The liquid sample is directly dropped on the transparent salt sheet, and the solid sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com