Thermoplastic low-fume halogen-free high-flame retardance polyolefin insulation material and preparation method thereof

A thermoplastic, high flame-retardant technology, applied in the direction of plastic/resin/wax insulators, insulated conductors, insulated cables, etc., can solve the problem that low-smoke and halogen-free materials cannot pass the bundle combustion test, insulation materials have poor heat resistance, and release Eliminate toxic gas and dense smoke and other problems, and achieve the effect of facilitating pipe penetration construction, improving surface smoothness, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

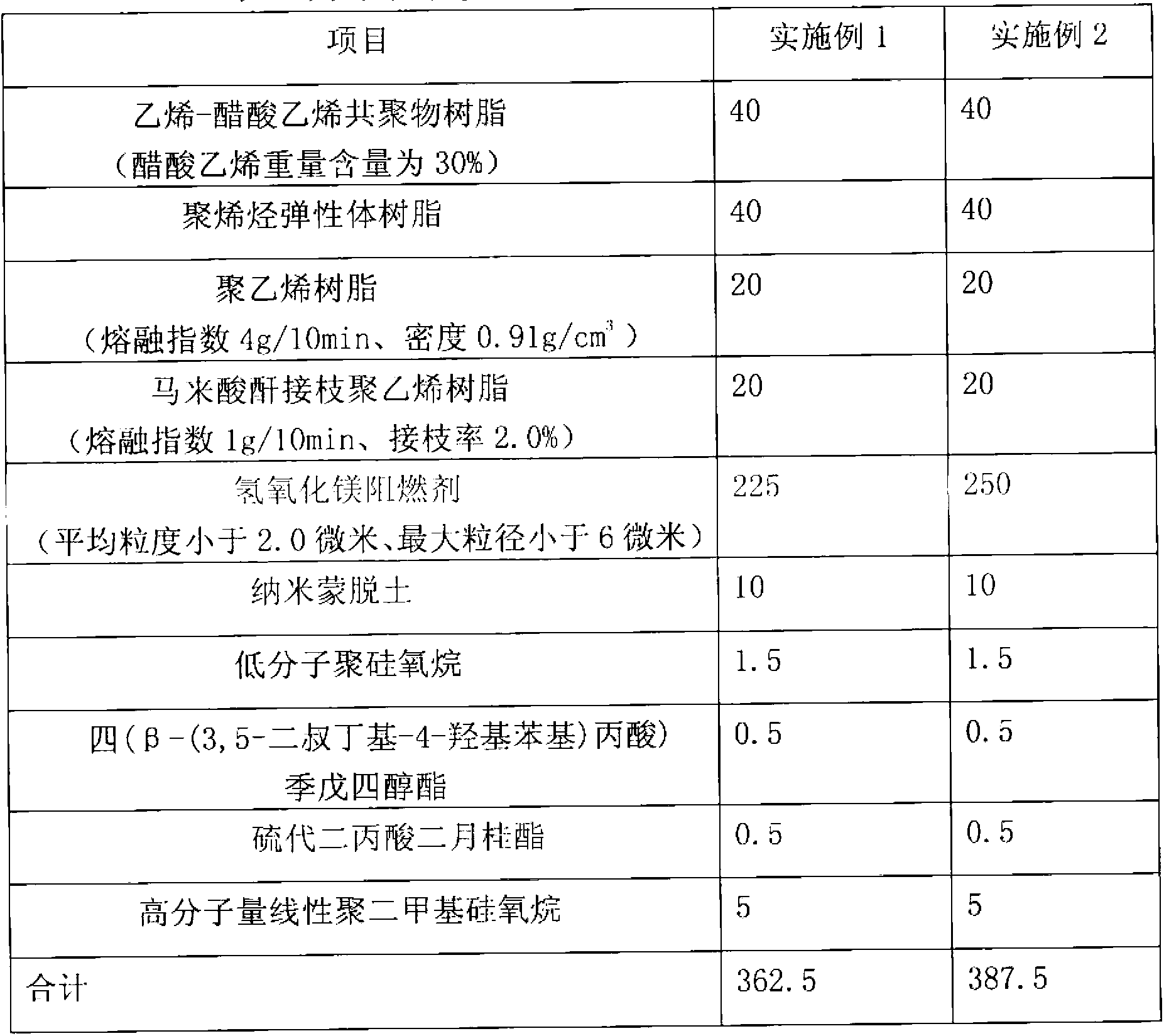

[0016] Embodiment 1 and embodiment 2 are prepared according to the parts by weight of each component shown in table 1:

[0017] Table 1 is the parts by weight table of each component of the embodiment of the present invention

[0018]

[0019] The preparation of embodiment 1:

[0020] The raw materials are prepared according to the respective weight parts shown in Table 1, and then put into a 55-liter pressurized kneader and mixed evenly. The mixing temperature is 120 ° C, and then sent into a single-screw extruder with a diameter of 120 mm to extrude and pelletize , the extrusion temperature is 110°C, the extrusion speed is 200 rpm, and then sieved through a vibrating sieve, and finally cooled to below 50°C for packaging to obtain the finished product.

Embodiment 2

[0021] The preparation of embodiment 2:

[0022] The raw materials are prepared according to the respective weight parts shown in Table 1, and then put into a 55-liter pressurized kneader and mixed evenly. The mixing temperature is 140 ° C, and then sent into a single-screw extruder with a diameter of 120 mm to extrude and pelletize , the extrusion temperature is 150°C, the extrusion speed is 300 rpm, and then sieved through a vibrating sieve, and finally cooled to 50°C, and packaged to obtain a finished product.

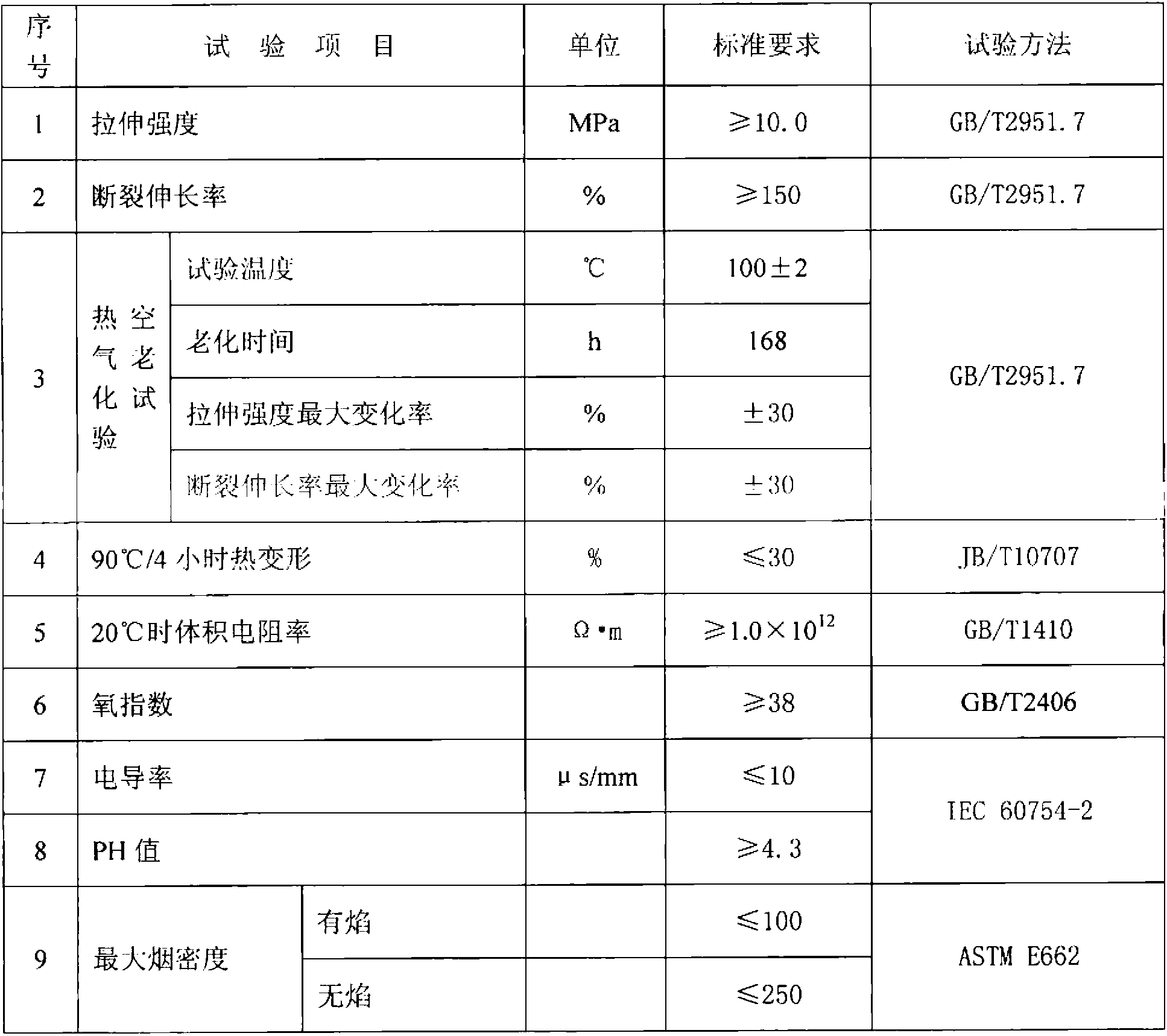

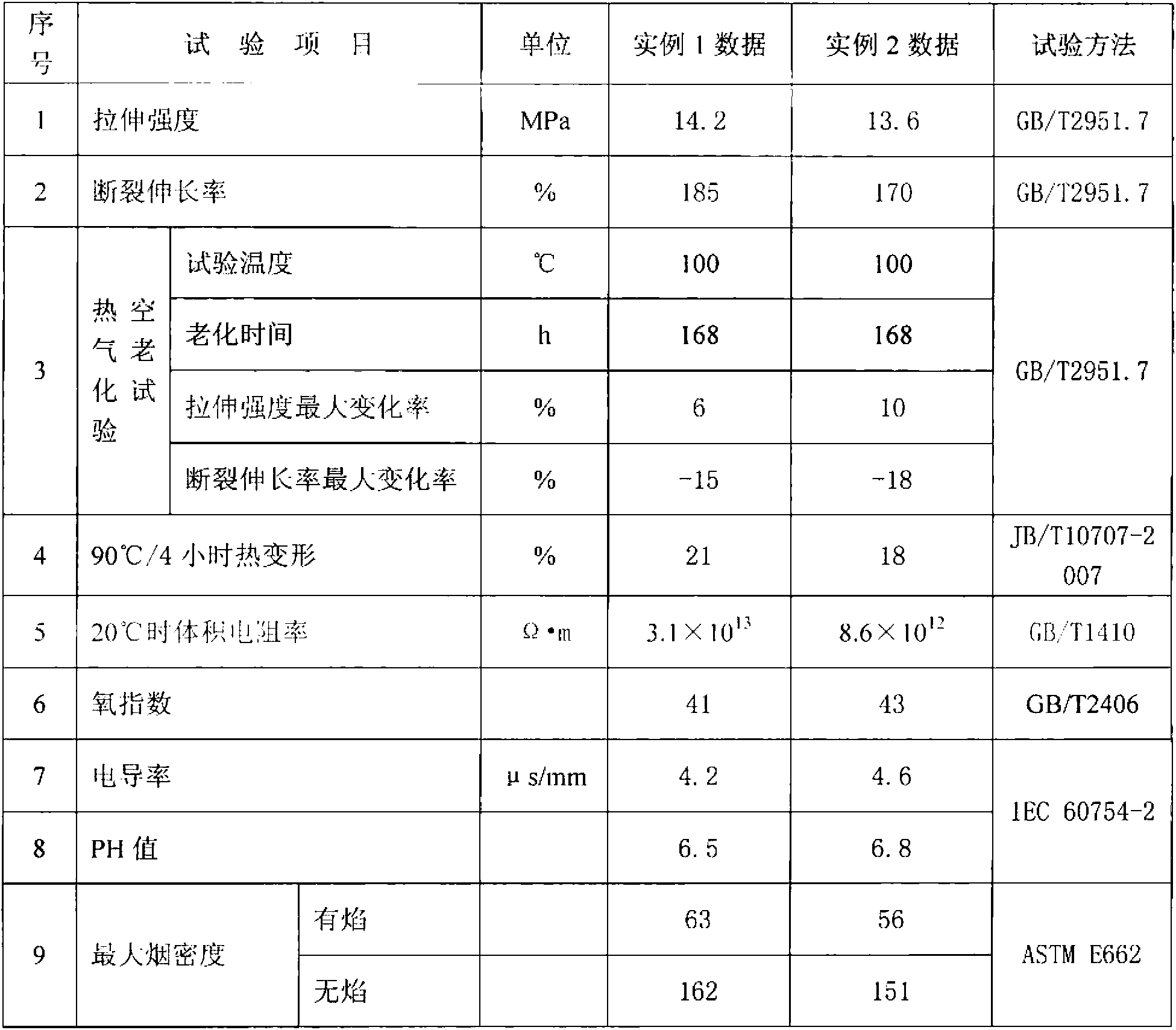

[0023] The main properties of the thermoplastic low-smoke, halogen-free and highly flame-retardant polyolefin insulating material prepared in the embodiment of the present invention are shown in Table 2:

[0024] Table 2 is the main performance table of the thermoplastic low-smoke, halogen-free and highly flame-retardant polyolefin insulating material prepared in the embodiment of the present invention

[0025]

[0026] After adopting the prepared insulating mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com