Method for preparing layered K2Ti4O9 continuous nanofiber

A nanofiber, butyl titanate technology, applied in fiber processing, spinning solution preparation, chemical instruments and methods, etc., can solve the problems of difficult control of process conditions, small aspect ratio of nanofibers, complicated preparation process, etc. The effect of convenient operation, simple process and simple production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

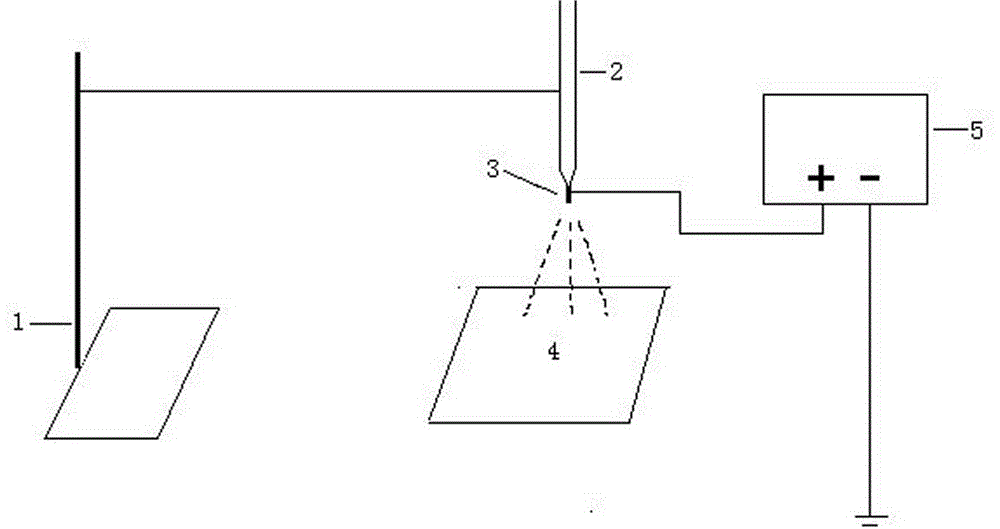

Method used

Image

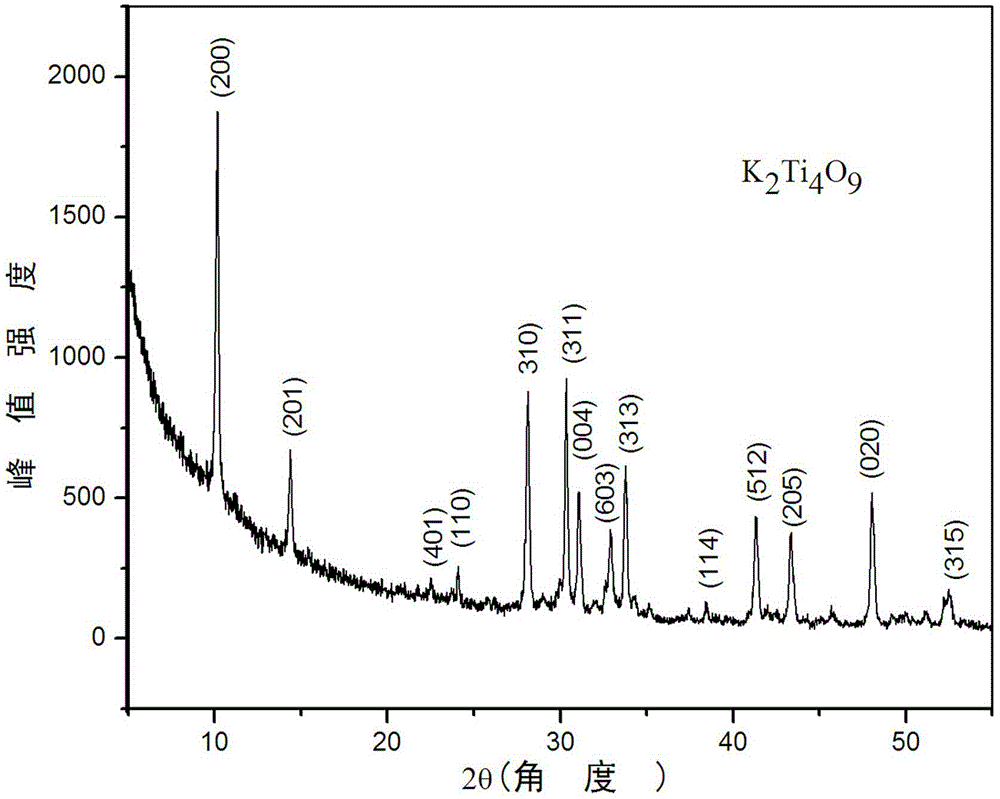

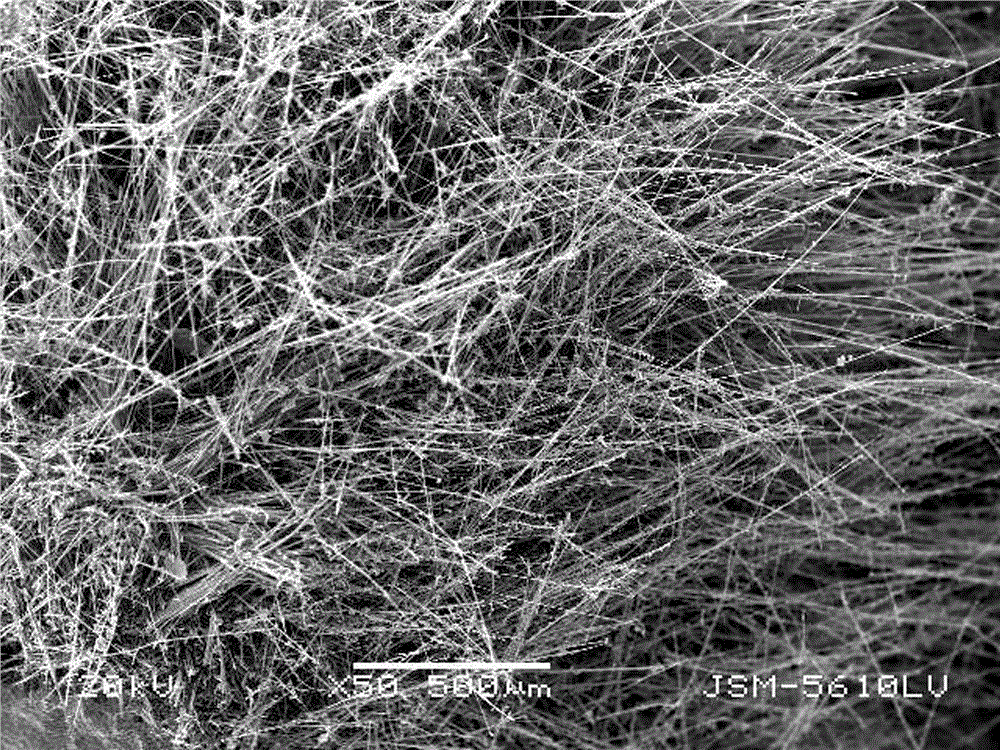

Examples

Embodiment 1

[0032] 1. Preparation of spinning solution

[0033] First prepare the sol solution: drop 0.5-1ml of acetylacetone into 6.8g of butyl titanate, stir for 20 minutes, then drop in the ethanol solution of citric acid, stir for 40 minutes after dropping, and then slowly drop in 2.02g of KNO 3 Nitric acid solution of 0.32 g of CTAB was added dropwise after stirring for 40 min. After dropping, continue to stir and react for one hour to form a uniform and transparent light yellow sol solution; then prepare polyvinyl alcohol aqueous solution: mix polyvinyl alcohol and water in a mass ratio of 1:50, heat and stir at about 90°C for 2 -3 hours, then let it stand and cool to room temperature to obtain an aqueous solution of polyvinyl alcohol; finally prepare the spinning solution: add the sol solution obtained above to the aqueous solution of polyvinyl alcohol dropwise at a volume ratio of 1:4, and Stirring for 1h, the sol-like [KNO 3 -Ti(OC 2 h 5 ) 4 ] / the spinning solution of polyvi...

Embodiment 2

[0039] 1. Preparation of spinning solution

[0040] First prepare the sol solution: drop 0.5-1ml of acetylacetone into 6.8g of butyl titanate, stir for 20 minutes, then drop in the ethanol solution of citric acid, stir for 40 minutes after dropping, and then slowly drop in 2.02g of KNO 3 Nitric acid solution of 0.55 g of CTAB was added dropwise after stirring for 40 min. After dropping, continue to stir and react for one hour to form a uniform and transparent light yellow sol solution; then prepare polyvinyl alcohol aqueous solution: mix polyvinyl alcohol and water in a mass ratio of 1:100, heat and stir at about 90°C for 2 -3 hours, then let it stand and cool to room temperature to obtain an aqueous solution of polyvinyl alcohol; finally prepare the spinning solution: add the sol solution obtained above to the aqueous solution of polyvinyl alcohol dropwise at a volume ratio of 1:2, and stir at room temperature 1h, the sol-like [KNO 3 -Ti(OC 2 h 5 ) 4 ] / the spinning solut...

Embodiment 3

[0046] 1. Preparation of spinning solution

[0047] First prepare the sol solution: drop 0.5-1ml into 6.8g butyl titanate, stir for 20min, then drop into the ethanol solution of citric acid, then stir for 40min after dropping, then slowly drop into 2.02g of KNO 3 Nitric acid solution of 0.45 g of CTAB was added dropwise after stirring for 40 min. After dropping, continue to stir and react for one hour to form a uniform and transparent light yellow sol solution; then prepare polyvinyl alcohol aqueous solution: mix polyvinyl alcohol and water in a mass ratio of 1:100, heat and stir at about 90°C for 2 -3 hours, then let it stand and cool to room temperature to obtain an aqueous solution of polyvinyl alcohol; finally prepare the spinning solution: add the sol solution obtained above to the aqueous solution of polyvinyl alcohol dropwise at a volume ratio of 1:2, and stir at room temperature 1h, the sol-like [KNO 3 -Ti(OC 2 h 5 ) 4 ] / polyvinyl alcohol spinning solution;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com