Method for preparing docusate sodium soft capsules

A kind of technology of docusate sodium and soft capsule

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method comprises the following steps:

[0031] A. Preparation of red gelatin solution

[0032] Dissolve the plasticizer in water, add it into the glue tank and heat it to 40-80°C, add gelatin, stir and dissolve at 60-80°C to obtain a gelatin solution, add the colorant I to the water, stir evenly, and obtain the pigment solution, add the pigment solution into the gelatin solution, stir and vacuumize to remove air bubbles, and set aside; the weight ratio of water and gelatin is 0.8~1.2:1.

[0033] B. Preparation of white gelatin solution

[0034] Add the additives into a sufficient amount of water, disperse the colloid mill evenly, and obtain the solution I, dissolve the plasticizer in water, add the solution I and the plasticizer solution into the glue tank and heat to 40-80°C, add gelatin, 60-80°C Stir to dissolve at ℃. After the solution is complete, vacuum to remove air bubbles and set aside; the weight ratio of water to gelatin is 0.8~1.2:1.

[003...

Embodiment 1

[0041] The present invention prepares the method for docusate sodium soft capsule, and this docusate sodium soft capsule comprises the two-color soft capsule rubber skin that is made of red gelatin liquid and white gelatin liquid, and docusate sodium is housed in the two-color soft capsule rubber skin Contents, wherein the content of docusate sodium in the finished product of docusate sodium soft capsule consists of the following components by weight percentage:

[0042] Docusate Sodium 10%

[0043] Polyethylene glycol 80%

[0044] Polyol 15%;

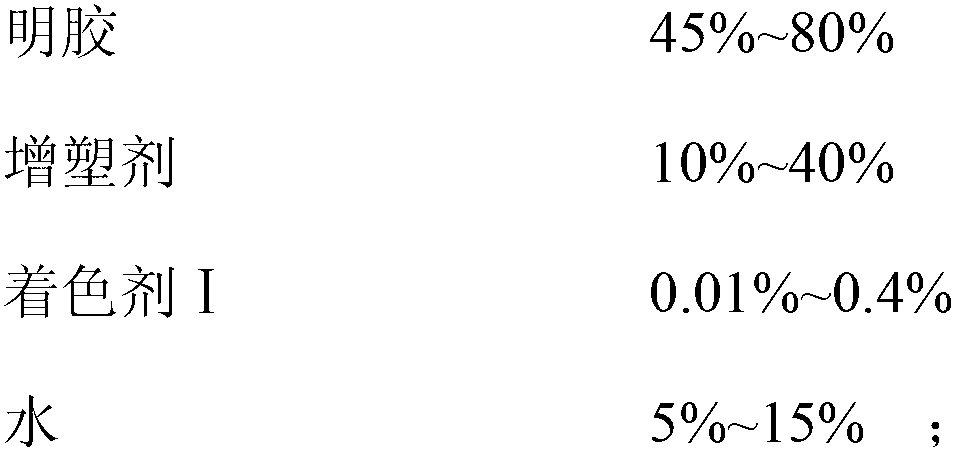

[0045] The red rubber consists of the following components by weight percentage:

[0046]

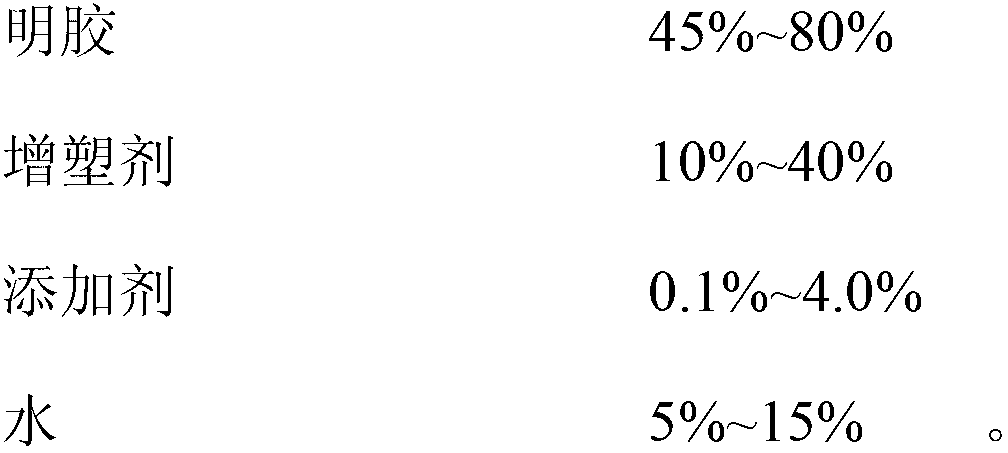

[0047] The white rubber consists of the following components by weight percentage:

[0048]

[0049] The preparation method comprises the following steps:

[0050] A. Preparation of red gelatin solution

[0051] Dissolve the plasticizer in water, add it into the glue tank and heat it to 40°C, add gelatin, stir and dissolve at 60°C to ...

Embodiment 2

[0060] The present invention prepares the method for docusate sodium soft capsule, and this docusate sodium soft capsule comprises the two-color soft capsule rubber skin that is made of red gelatin liquid and white gelatin liquid, and docusate sodium is housed in the two-color soft capsule rubber skin Contents, wherein the content of docusate sodium in the finished product of docusate sodium soft capsule consists of the following components by weight percentage:

[0061] Docusate Sodium 50%

[0062] Polyethylene glycol 35%

[0063] Polyol 15%;

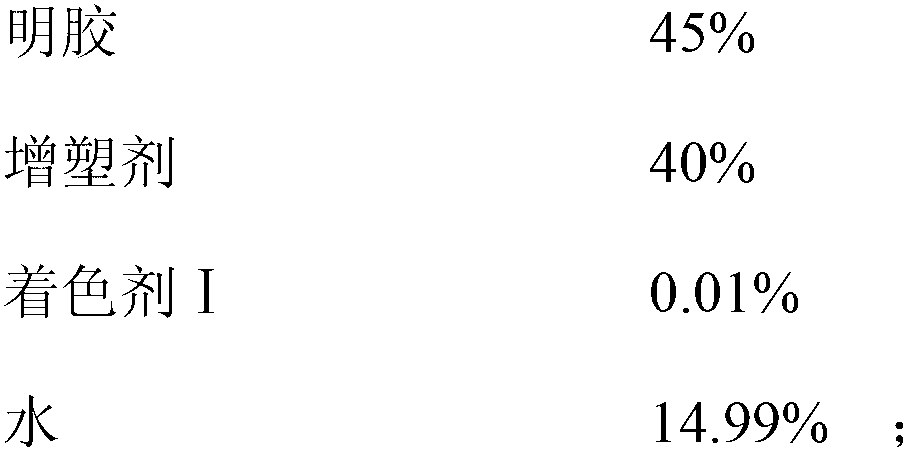

[0064] The red rubber consists of the following components by weight percentage:

[0065]

[0066] The white rubber consists of the following components by weight percentage:

[0067]

[0068] The preparation method comprises the following steps:

[0069] A. Preparation of red gelatin solution

[0070] Dissolve the plasticizer in water, add it into the glue tank and heat it to 80°C, add gelatin, stir and dissolve at 80°C to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com