Catalyst as well as preparation method and application thereof

A catalyst and concentration technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of high investment and operating costs, large amount of adsorbent, difficult solution handling, etc., to reduce energy consumption and low cost , Realize the effect of resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

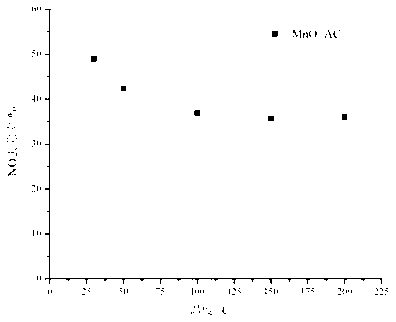

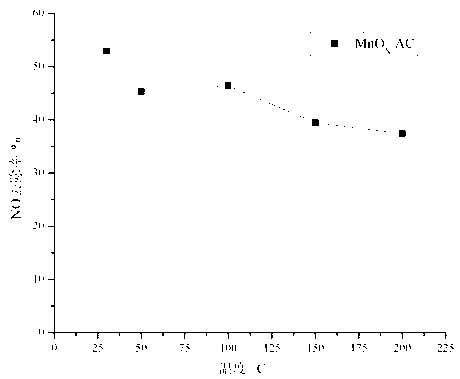

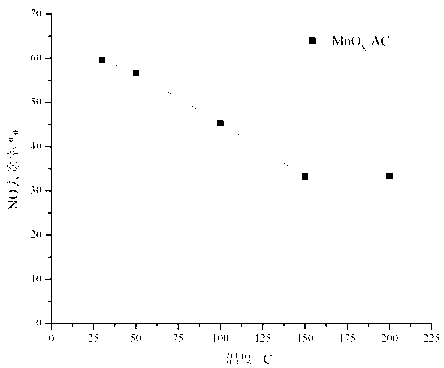

Image

Examples

Embodiment 1

[0027] Example 1: The specific operation of the preparation method of the catalyst is as follows:

[0028] (1) The carrier activated carbon is crushed to 40-60 mesh, and then immersed in nitric acid with a concentration of 30% by mass, ethanol with a concentration of 30% by mass, and distilled water successively, and ultrasonically washed for 40 minutes at room temperature and 40 Hz, and then at 100 ℃ Dry at constant temperature for 3h;

[0029] (2) Mix manganese acetate with water to make a solution with a concentration of 0.01 mol / l ; Add 20% hydrofluoric acid solution to the solution Mixture , Where F - : Mn 2+ The molar ratio is 3; add concentrated ammonia to the mixed liquid In, make a mixture , Mixture pH is 10.1; keep Mn 2+ The mass ratio to activated carbon is 0.1, and the treated activated carbon is immersed in the mixed liquid Heating and stirring in medium, depositing at 50℃ for 2h, the number of depositions is 3; the precipitate is filtered, dried at 100℃ for 3h...

Embodiment 2

[0031] Example 2: The specific operation of the preparation method of the catalyst is as follows:

[0032] (1) The carrier activated carbon is crushed to 40-60 mesh, and then immersed in nitric acid with a concentration of 50% by mass, ethanol with a concentration of 10% by mass, and distilled water. Wash it ultrasonically for 20 minutes at room temperature and 40Hz, and then at 110℃ Dry under constant temperature for 2h;

[0033] (2) Mix manganese nitrate and water to make solution I with a concentration of 0.05 mol / l; add a hydrofluoric acid solution with a mass percentage concentration of 10% to solution I to make mixed solution II, where F - : Mn 2+ The molar ratio is 4; add concentrated ammonia water to the mixed solution II to prepare the mixed solution III, the pH of the mixed solution III is 8.4; keep Mn 2+ The mass ratio to activated carbon is 0.9. The treated activated carbon is immersed in mixed solution III, heated and stirred, and deposited at 60°C for 1 hour, and the ...

Embodiment 3

[0035] Example 3: The specific operation of the preparation method of the catalyst is as follows:

[0036] (1) Crush the carrier activated carbon to 40-60 meshes, immerse it in nitric acid with a concentration of 40% by mass, ethanol with a concentration of 20% by mass, and distilled water successively, and wash with 40Hz ultrasonic at room temperature for 30 minutes, and then at 120℃ Constant temperature drying for 1h;

[0037] (2) Mix manganese chloride with water to make a solution with a concentration of 0.03mol / l ; Add 40% hydrofluoric acid solution to the solution Mixture , Where F - : Mn 2+ The molar ratio is 5; add concentrated ammonia water to the mixed solution In, make a mixture , Mixture pH is 9.3; keep Mn 2+ The mass ratio to activated carbon is 0.5, and the treated activated carbon is immersed in the mixed liquid Heating and stirring in medium, depositing at 40℃ for 4h, the number of deposition is 2; the precipitate is filtered, dried at 120℃ for 1h, and calci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com