Carbon nano composite and preparation method thereof

A technology for carbon nanomaterials and composite materials, applied in the field of carbon nanocomposite materials and their preparation, can solve the problems of cumbersome reaction steps, complex preparation process, low degree of functionalization, etc., and achieves shortened calcination time, simple preparation process, and decomposition products. single effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

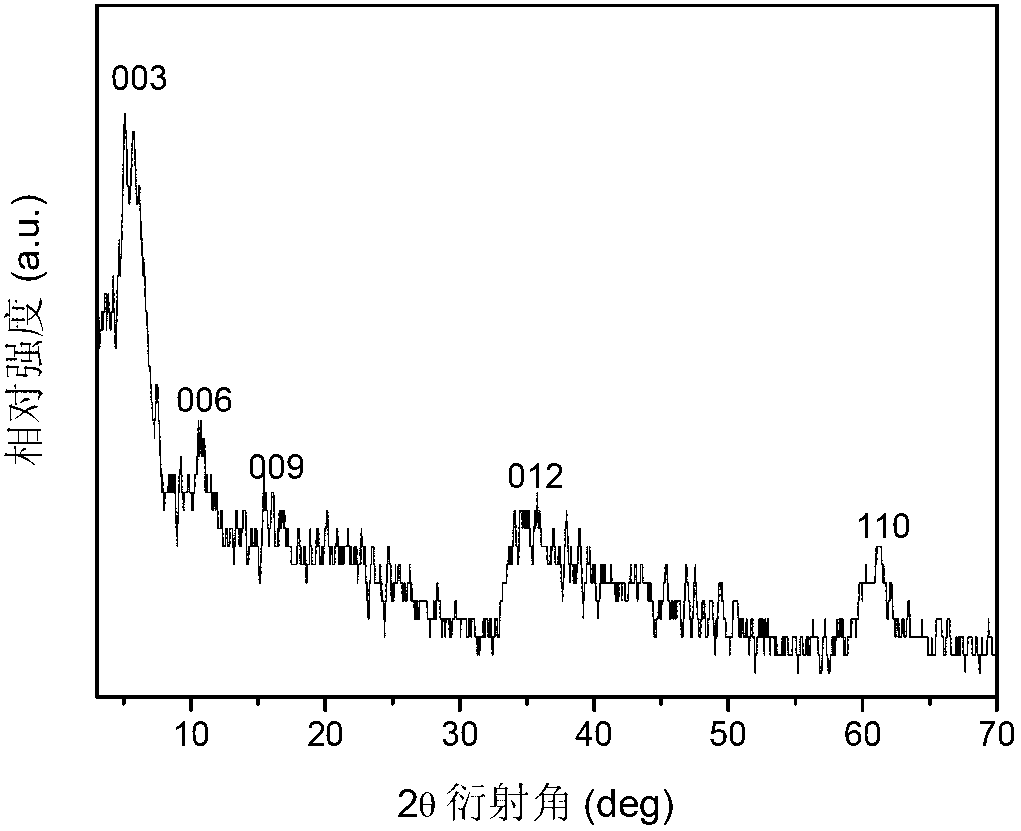

[0035] Step A: Weigh 11.64g of Co(NO 3 ) 2 ·6H 2 O and 7.5g of Al(NO 3 ) 3 ·9H 2 O was added to deionized water to prepare a 50ml mixed solution, 12.81g of sodium salicylate was weighed and dissolved in 100mL of deionized water, and 8g of NaOH was weighed into deionized water to prepare 100mL of a 2M alkaline solution. Under mechanical stirring, the mixed salt solution and NaOH solution were simultaneously added dropwise to the sodium salicylate solution. The pH of the solution was maintained at 7 during the dropping process, and the obtained slurry was transferred to an autoclave for crystallization at 100° C. for 24 hours. After the crystallization is completed, after the temperature drops to room temperature, it is washed with deionized water, centrifuged 4 times, and dried at 60°C for 12 hours to obtain a cobalt-aluminum hydrotalcite precursor intercalated with salicylate.

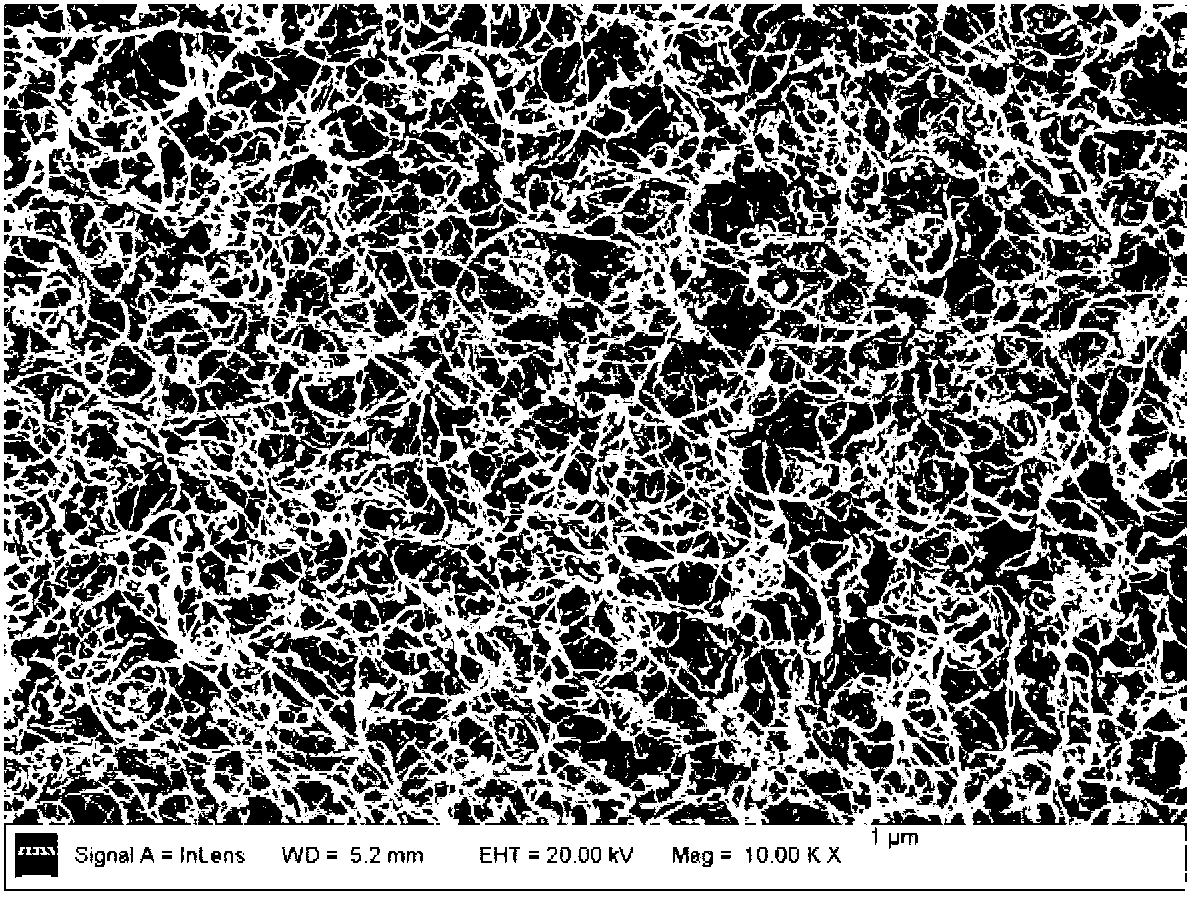

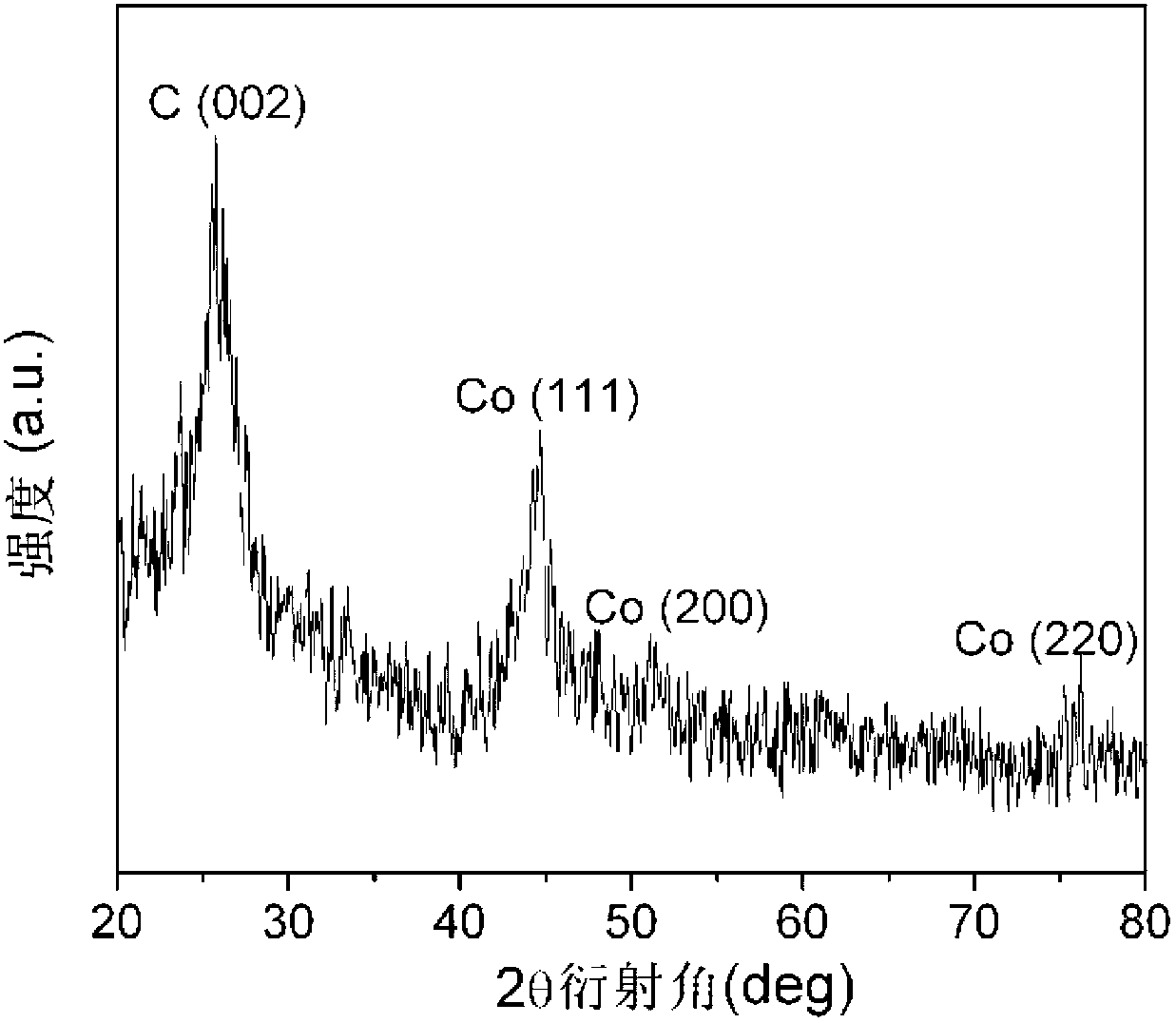

[0036] Step B: Weigh 1.5g of hydrotalcite precursor after grinding, spread it evenly on a porcelain boa...

Embodiment 2

[0039] Step A: Weigh 11.63g Ni(NO 3 ) 2 ·6H 2 O and 7.5g of Al(NO 3 ) 3 ·9H 2 O was added to deionized water to prepare a 50ml mixed solution, 12.81g of sodium salicylate was weighed and dissolved in 100mL of deionized water, and 8g of NaOH was weighed into deionized water to prepare 100mL of a 2M alkaline solution. Under mechanical stirring, the mixed salt solution and NaOH solution were simultaneously added dropwise to the sodium salicylate solution. The pH of the solution was maintained at 7 during the dropping process, and the obtained slurry was transferred to an autoclave for crystallization at 100° C. for 24 hours. After the crystallization is completed, after the temperature drops to room temperature, it is washed with deionized water, centrifuged 4 times, and dried at 60°C for 12 hours to obtain a salicylate intercalated nickel aluminum hydrotalcite precursor.

[0040] Step B: Weigh 1.5g of hydrotalcite precursor after grinding, spread it evenly on a porcelain boat and pl...

Embodiment 3

[0042] Step A: Weigh 11.64g of Co(NO 3 )2·6H 2 O and 7.5g of Al(NO 3 ) 3 ·9H 2 O was added to deionized water to prepare a 50ml mixed solution, 12.81g of sodium salicylate was weighed and dissolved in 100mL of deionized water, and 8g of NaOH was weighed into deionized water to prepare 100mL of a 2M alkaline solution. Under mechanical stirring, the mixed salt solution and NaOH solution were simultaneously added dropwise to the sodium salicylate solution. The pH of the solution was maintained at 7 during the dropping process, and the obtained slurry was transferred to an autoclave for crystallization at 100° C. for 24 hours. After the crystallization is completed, after the temperature drops to room temperature, it is washed with deionized water, centrifuged 4 times, and dried at 60°C for 12 hours to obtain a cobalt-aluminum hydrotalcite precursor intercalated with salicylate.

[0043] Step B: Weigh 1.5g of hydrotalcite precursor after grinding, spread it evenly on a porcelain boat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com