Method for preparing triphenylphosphine

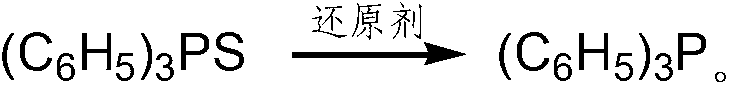

A technology of triphenylphosphine and triphenylphosphine sulfide, applied in the field of preparation of triphenylphosphine, can solve the problems of difficult control of chlorobenzene and phosphorus trichloride, complicated reaction steps, multiple reactions in addition amount, etc. The effect of easy to master the amount of ingredients, easy control of the reaction process and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add 48g (0.36mol) of aluminum trichloride, 3.85g (0.12mol) of sublimed sulfur, 16.55g (0.12mol) of phosphorus trichloride and 150mL of excess benzene into a 250mL round-bottomed flask with a reflux device, and heat to The internal reactants are in a state of strong reflux, the reflux temperature is 75-80°C, and the reaction is stirred for 8 hours. After the reaction, the product was slowly poured into 400mL of ice-water mixture to dissolve and cool, stirred, left for a while, separated, and the organic phase was separated, and the aqueous phase was extracted three times with benzene to extract the organic phase. The organic phases were combined, dried with anhydrous sodium sulfate, the solvent benzene was distilled off, and then recrystallized with acetone-water to obtain white triphenylphosphine sulfide crystals. Then mix 8.4g (0.15mol) of triphenylthiophosphine and reduced iron powder and put it into a round-bottomed three-neck flask, stir and react at 350°C for 2 hou...

Embodiment 2

[0019] Add 48g (0.36mol) of aluminum trichloride, 3.85g (0.12mol) of sublimed sulfur, 16.55g (0.12mol) of phosphorus trichloride and 150mL of excess benzene into a 250mL round-bottomed flask with a reflux device, and heat to The internal reactants are in a state of strong reflux, the reflux temperature is 90-100°C, and the reaction is stirred for 9 hours. After the reaction, the product was slowly poured into 400mL of ice-water mixture to dissolve and cool, stirred, left for a while, separated, and the organic phase was separated, and the aqueous phase was extracted three times with benzene to extract the organic phase. The organic phases were combined, dried with anhydrous sodium sulfate, the solvent benzene was distilled off, and then recrystallized with acetone-water to obtain white triphenylphosphine sulfide crystals. Then mix 9.8g (0.15mol) of triphenylthiophosphine and reduced zinc powder and put it into a three-necked round-bottomed flask. Stir and react at 370°C for 3 ...

Embodiment 3

[0020] Add 48g (0.36mol) of aluminum trichloride, 3.85g (0.12mol) of sublimed sulfur, 16.55g (0.12mol) of phosphorus trichloride and 150mL of excess benzene into a 250mL round-bottomed flask with a reflux device, and heat to The internal reactants are in a state of strong reflux, the reflux temperature is 75-80°C, and the reaction is stirred for 8 hours. After the reaction, the product was slowly poured into 400mL of ice-water mixture to dissolve and cool, stirred, left for a while and then separated, and the organic phase was separated, and the aqueous phase was extracted three times with benzene to extract the organic phase. The organic phases were combined, dried with anhydrous sodium sulfate, the solvent benzene was distilled off, and then recrystallized with acetone-water to obtain white triphenylphosphine sulfide crystals. Then mix 8.8g (0.15mol) of triphenylthiophosphine and reduced nickel powder and put it into a three-necked round-bottomed flask. Stir and react at 400...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com