Polymer emulsion containing infrared absorption dye and preparation method thereof

A technology of polymer emulsion and infrared absorption, applied in the direction of photosensitive materials used in optomechanical equipment, etc., can solve the problems of reduced sensitivity of heat-sensitive materials, easy decomposition, and non-environmental protection of emulsions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

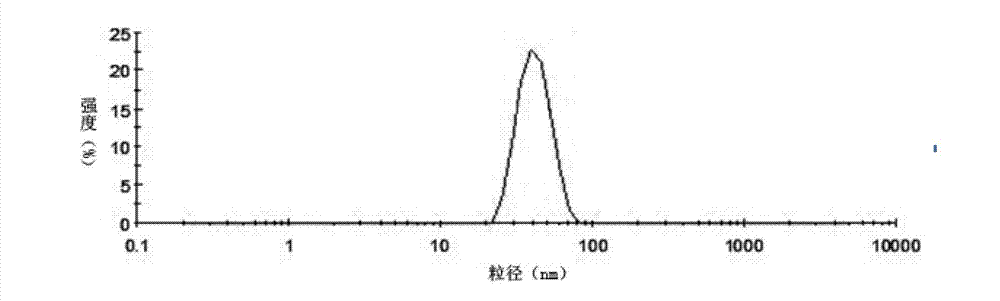

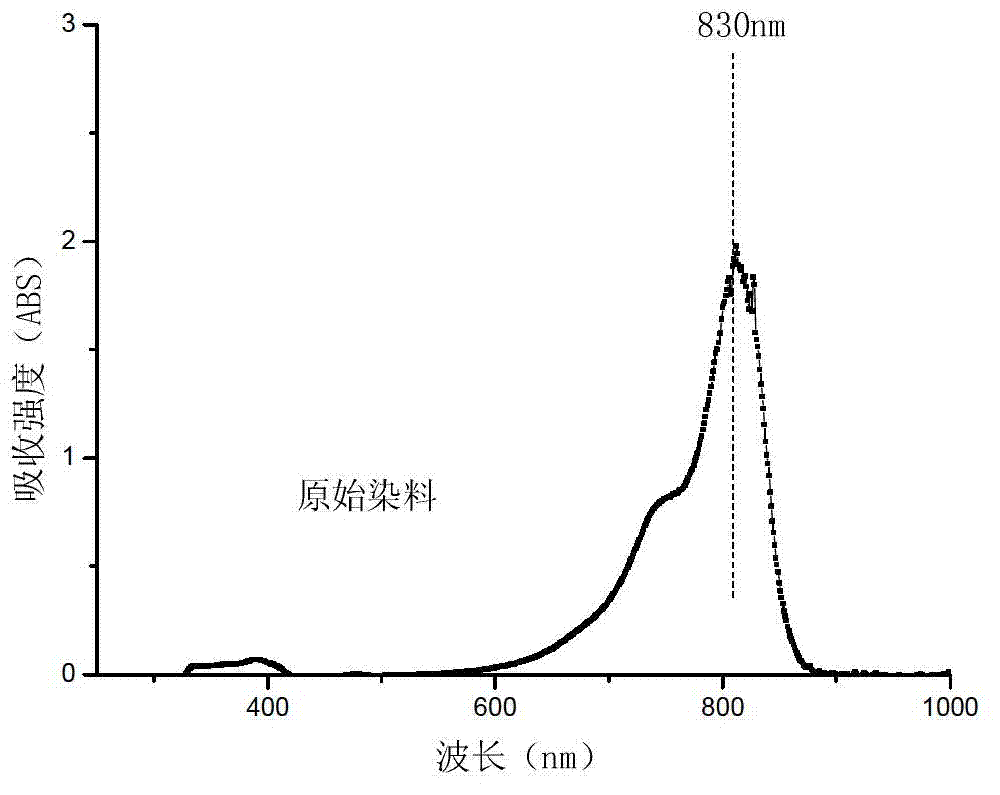

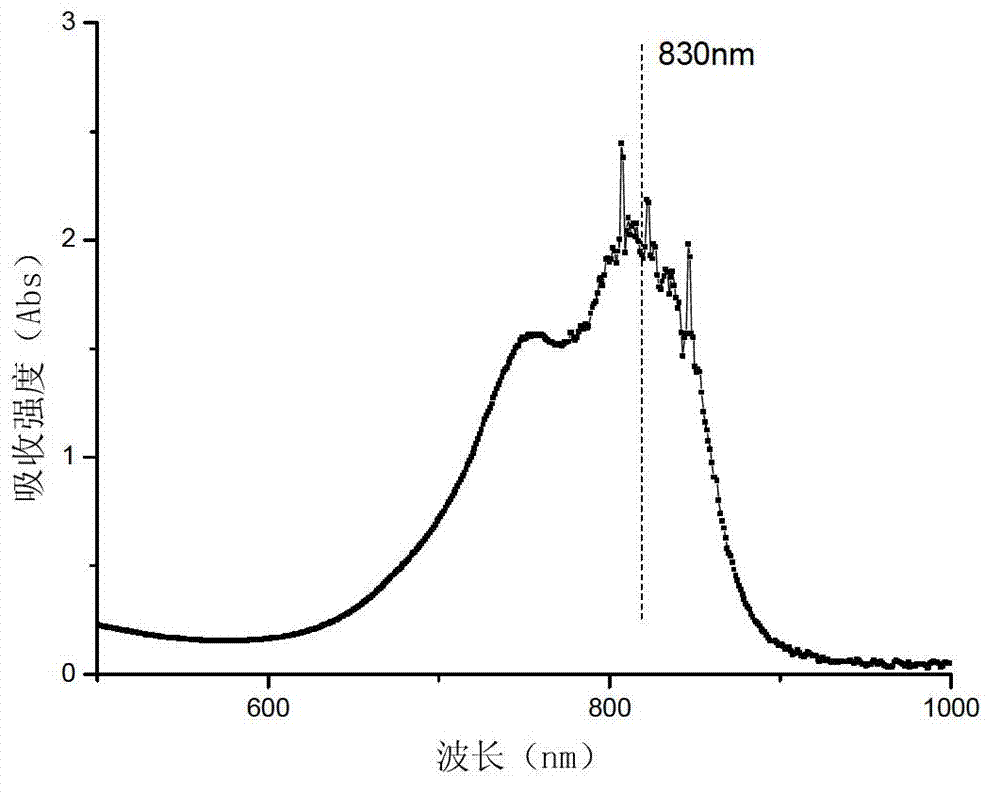

[0067] Infrared absorbing dyes (structures such as Figure 7 ) 5%, polystyrene nanospheres 25%, sodium lauryl sulfate 3%, ethylene glycol 0.2%, and deionized water 66.8%.

[0068] Preparation:

[0069] Oil phase preparation, 5% infrared absorbing dye (structure such as Figure 7 ), 25% styrene was dissolved evenly and added to the reaction flask, and mixed evenly;

[0070] The water phase is prepared by adding: 66.8% of water, 3% of sodium lauryl sulfate, 0.2% of ethylene glycol and 6% of the tert-butyl hydroperoxide solution to the deionized water mass reaction flask, and stir evenly to obtain a mixed solution;

[0071] After the water phase and the oil phase prepared in the above two steps are uniformly mixed, they are stirred under a homogenizer for 8 minutes to obtain a pre-emulsified mixture.

[0072] Finally, at 30°C, after mechanical stirring and emulsification for 20 minutes, a 6% ferrous sulfate aqueous solution accounting for 3% of the mass of deionized water was...

Embodiment 2

[0074] Infrared absorbing dyes (structures such as Figure 8 ) 7%, Polymethyl Methacrylate Nanospheres 40%, Sodium Laureth Sulfate 10%, Glycerin 1.5%, and Deionized Water 41.5%.

[0075] Preparation:

[0076] Oil phase preparation, 7% infrared absorbing dye (structure such as Figure 8 ), 40% methyl methacrylate was dissolved evenly and added to the reaction bottle, and mixed evenly;

[0077] Water phase preparation, will include: water 41.5%, sodium lauryl ether sulfate 10%, glycerol 1.5% and the tert-butyl hydroperoxide aqueous solution that mass fraction is 9% accounts for 5% of deionized water mass and joins in reaction bottle, and stir evenly to obtain a mixed solution;

[0078] After the water phase and the oil phase prepared in the above two steps are uniformly mixed, they are stirred under a homogenizer for 10 minutes to obtain a pre-emulsified mixed liquid.

[0079] Finally, at 30°C, after mechanical stirring and emulsification for 20 minutes, an aqueous solution ...

Embodiment 3

[0081] Infrared absorbing dyes (structures such as Figure 9 ) 2%, polystyrene-acrylonitrile copolymer 30%, the copolymer composition mass ratio is 3:1, trideceth phosphate 5%, cetyl alcohol 0.4% and deionized water 62.6%.

[0082] Preparation method: the structure is shown in the figure

[0083] Prepare the oil phase, dissolve 2% infrared absorbing dye (9), 30% styrene and acrylonitrile in a mass ratio of 3:1, add it into the reaction bottle, and mix well;

[0084] Water phase preparation, will include: water 62.6%, trideceth phosphate 5%, cetyl alcohol 0.4% and tert-butyl hydroperoxide aqueous solution with a mass fraction of 5%, accounting for 3% of the mass of deionized water added into the reaction flask, and stir evenly to obtain a mixed solution;

[0085] After the water phase and the oil phase prepared in the above two steps are uniformly mixed, they are stirred under a homogenizer for 5 minutes to obtain a pre-emulsified mixture.

[0086] Finally, at 30°C, after me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com