Non-formaldehyde and low-water solubility ammonium polyphosphate product and preparation method thereof

A technology of ammonium polyphosphate and low water solubility, which is applied in textiles and papermaking, coating, fiber treatment, etc. It can solve the problems of low processing efficiency, resin loss, short storage period, etc., and achieve the effect of simple and practical process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

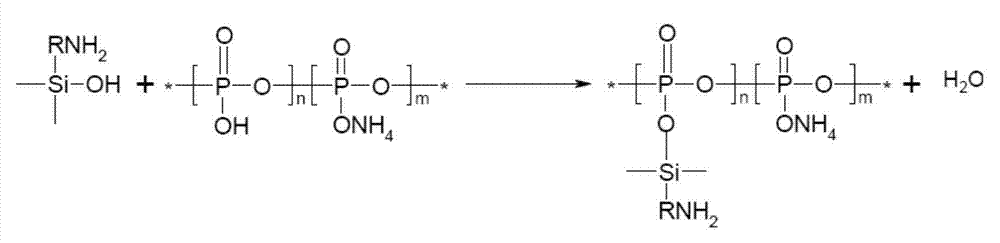

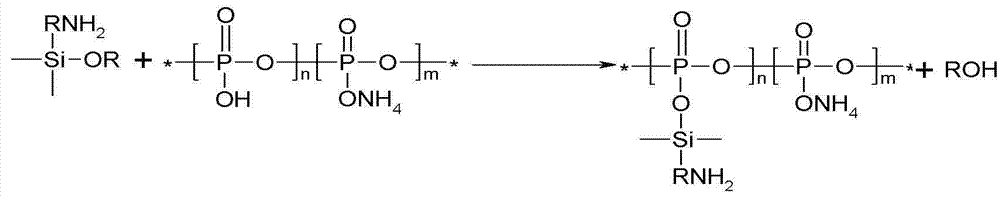

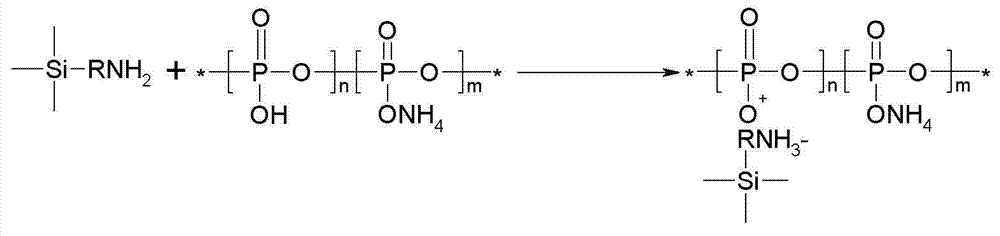

Method used

Image

Examples

Embodiment 1

[0036] At room temperature, add 150 kg of ammonium-deficient crystalline type II ammonium polyphosphate (average particle size 20 μm, pH = 2.2, acid value 5 mgKOH / g) into the kneader, stir, and spray at a speed of 80 rpm to add the mass of ammonium polyphosphate 2.0% gamma-aminopropyltrimethoxysilane, mixed for 50 minutes. Rise to 120°C and react for 2 hours. Cool to below 60°C to obtain ammonium polyphosphate (I) with aminosilane coupling agent grafted on the surface. I was added to the internal mixer, the stirring speed was controlled at 120rpm, and the organosilicon epoxy resin (epoxy value 0.20) of ammonium polyphosphate mass 5% was added, and stirred for 20 minutes. After heating up to 75°C, stir for 30 minutes; continue to heat up to 150°C, react for 1.5 hours, cool, and sieve to obtain formaldehyde-free and low-water-soluble ammonium polyphosphate (referred to as the product).

Embodiment 2

[0038] Spray and add 2.0% N-(β-aminoethyl)-γ-aminopropylmethyldimethoxysilane by mass of ammonium polyphosphate, and the remainder is the same as in Example 1.

Embodiment 3

[0040] Spray and add 2.0% by mass of ammonium polyphosphate γ-aminopropyltriethoxysilane, and the remainder is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com