Composite flora and pulping method by using biological bacterial liquid of composite flora

A technology of compound flora and biological bacteria, applied in microorganism-based methods, biochemical equipment and methods, fertilizers made from biological waste, etc., can solve the problems of difficult actual production, low fiber purity, and long reaction time, etc. To achieve the effect of saving coal consumption, reducing reaction time and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Example 1 Configuration of bacterial liquid

[0032] The biological flora used in the present invention has been deposited at the General Microbiology Center of the China Microbial Culture Collection Management Committee (CGMCC, No. 3, No. 1, Beichen West Road, Chaoyang District, Beijing) on April 6, 2012, and it contains the deposit number: Rheinheimera tangshanensis with CGMCC No.5972, Acinetobacter lwoffii with CGMCC No.5973, Pseudomonas fluorescens with CGMCC No.5974 .

[0033] The above-mentioned complex bacterial group is configured into a complex bacterial aqueous solution according to the following mass ratio, which is the bacterial liquid:

[0034] Tangshan Rheinoniae: Acinetobacter reuteri: Pseudomonas fluorescens is 1-3:1-2:1-2; the density of the formed bacterial solution is more than 60 million bacteria / ml, and it is reserved.

Embodiment 2

[0035] Example 2 Biological bacterial liquid pulping of woody raw materials

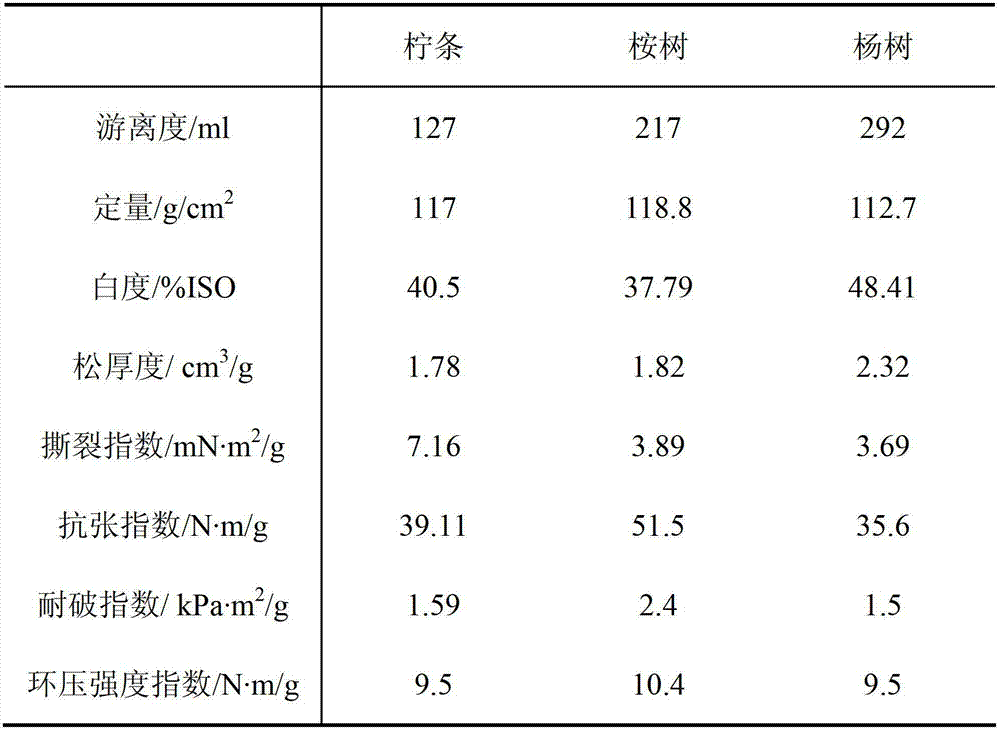

[0036] Using Caragana korshinskii as raw material, the method of pulping with biological bacteria liquid when woody raw material is used is specified. The biological pulping method of other woody raw materials, such as poplar and eucalyptus, can refer to this process. When Caragana korshinskii is used, the composite flora is configured according to the following mass ratio: Rheinella tangshanensis: Acinetobacter rouxii: Pseudomonas fluorescens is 1:2:2; when poplar is used, the composite flora is as follows The mass ratio is configured: Tangshan Rheinoniae: Acinetobacter reuteri: Pseudomonas fluorescens is 2:1:2; when eucalyptus is used, the composite flora is configured according to the following mass ratio: Tangshan Rheinonia: Acinetobacter reuteri: Pseudomonas fluorescens is 2:1:2.

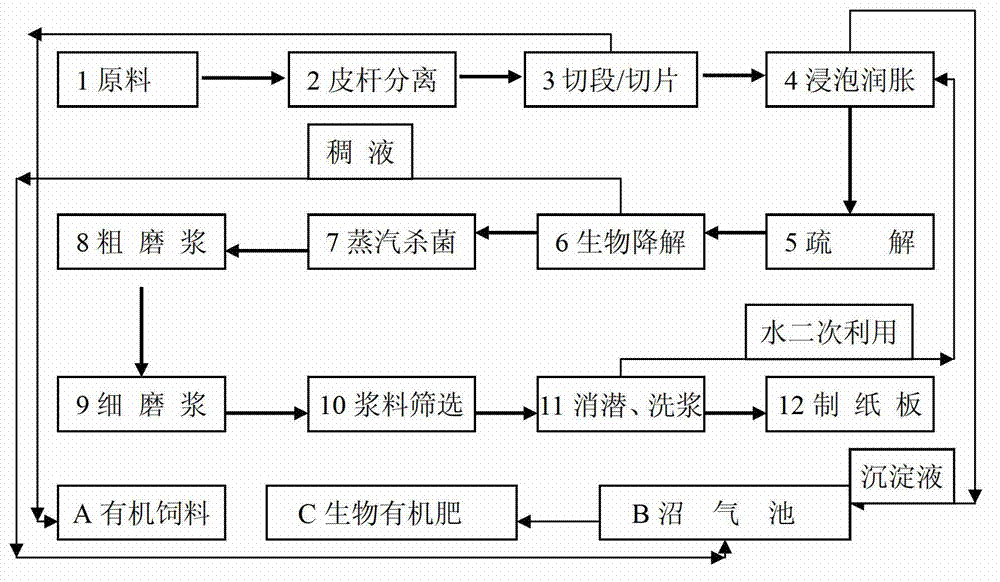

[0037] Please refer to figure 1 , The process of biological bacterial liquid pulping method is divided into three stag...

Embodiment 3

[0059] Example 3 Biological bacterial liquid pulping of herbal raw materials

[0060] Using wheat straw as the raw material, the biological bacteria liquid pulping method when using herbal raw materials is specified. The biological pulping method of other herbal raw materials, such as wheat straw, rice straw, and corn stover, can be carried out with reference to this process.

[0061] When wheat straw is used, the composite flora is configured according to the following mass ratio: Rheinonia tangshanensis: Acinetobacter reuteri: Pseudomonas fluorescens is 2:1:2; when straw is used, the composite flora is as follows Quality ratio configuration: Tangshan Rheinoniae: Acinetobacter ruckeri: Pseudomonas fluorescens is 3:1:2; when corn stalks are used, the composite flora is configured according to the following quality ratio: Tangshan Rheinoniae : Acinetobacter reuteri: Pseudomonas fluorescens is 2:2:1.

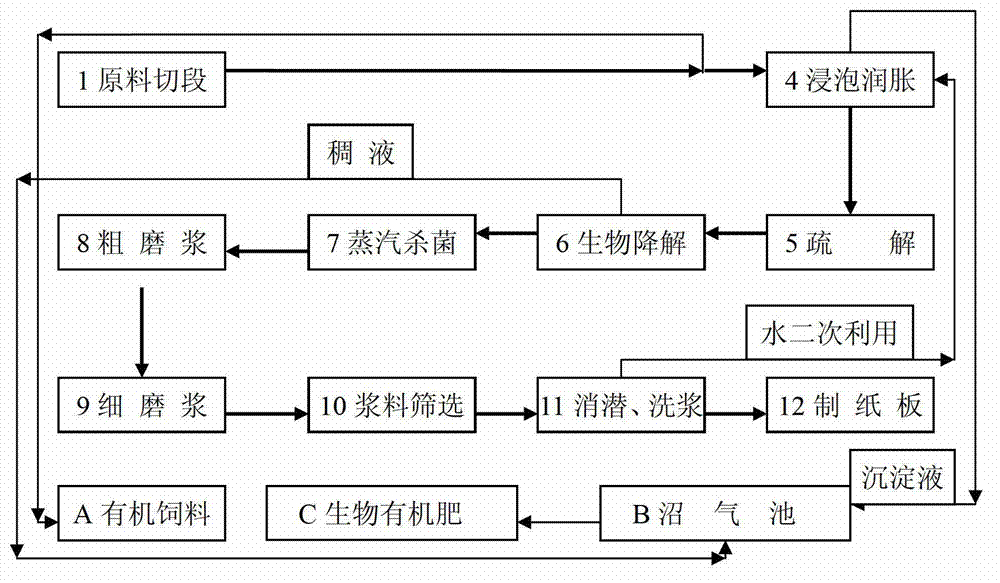

[0062] Please refer to figure 2 , The process of biological bacterial liquid pul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com