Supercapacitor combination electrode and making method thereof

A supercapacitor and composite electrode technology, applied in the field of capacitor electrodes, can solve the problems of limited resources and high price, and achieve the effects of large contact area, convenience, fast cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

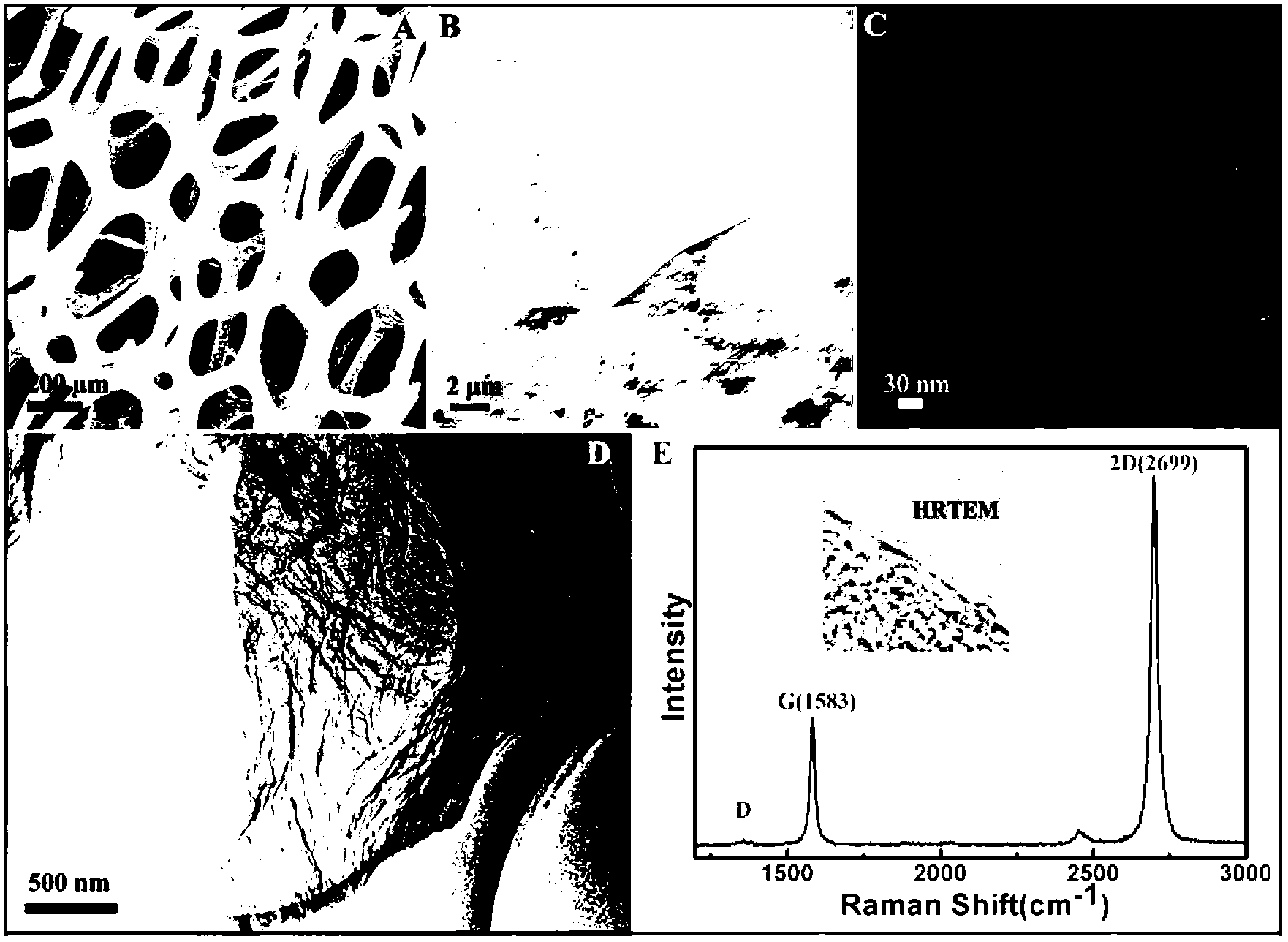

[0031] Place the nickel mesh (aperture 0.01mm) in a horizontal tube furnace, pass through argon (flow rate 500 s.c.c.m.) and hydrogen (200 s.c.c.m.) at 1000°C, heat for 10 minutes, remove the surface oxide layer, and then pass through Inject methane gas (5 s.c.c.m.), after 5 minutes, turn off the methane gas, keep the flow rate of argon and hydrogen constant, cool the sample to room temperature at a rate of 200°C / min, turn off the argon and hydrogen, and obtain a monolayer 3D graphene.

[0032] Electron microscopy scanning of single-layer three-dimensional graphene, such as figure 2 As shown in A-D, it can be seen that the graphene grown on the nickel mesh has a three-dimensional structure, and the surface is smooth and the thickness is relatively thin. figure 2 E shows that three-dimensional graphene is a single-layer structure.

Embodiment 2

[0034] Place the nickel mesh (aperture 0.1mm) in a horizontal tube furnace, pass in neon gas (flow rate 300 s.c.c.m.) and hydrogen gas (100 s.c.c.m.) at 800°C, heat for 10 minutes, remove the surface oxide layer, and then pass through Inject ethane gas (1 s.c.c.m.), after 10 minutes, turn off the ethane gas, keep the flow rate of neon and hydrogen constant, cool the sample to room temperature at a rate of 200°C / min, and turn off the neon and hydrogen.

Embodiment 3

[0036]Place the nickel mesh (aperture 0.6mm) in a horizontal tube furnace, pass through argon gas (flow rate 400 s.c.c.m.) and hydrogen gas (150 s.c.c.m.), and heat at 1300°C for 5 minutes. After removing the surface oxide layer, use Argon (6 s.c.c.m.) was bubbled in the tank of methanol, and after 2 minutes of methanol gas, the methanol gas was turned off, and the flow rate of argon and hydrogen was kept constant, and the sample was rapidly cooled to room temperature at a rate of 300°C / min. , turn off the argon and hydrogen.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com