Production of biodiesel by yeast from lignocellulose and glycerol

A technology of microorganisms and free fatty acids, which is applied in the direction of enzymes, biofuels, biochemical equipment and methods, and can solve problems such as development, stability and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

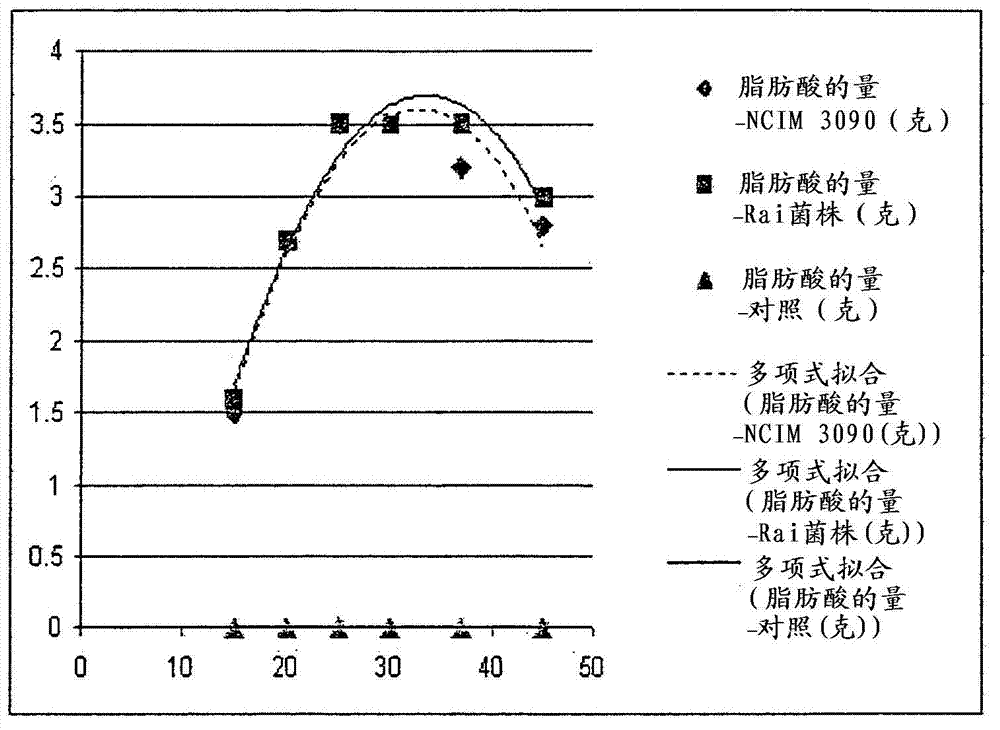

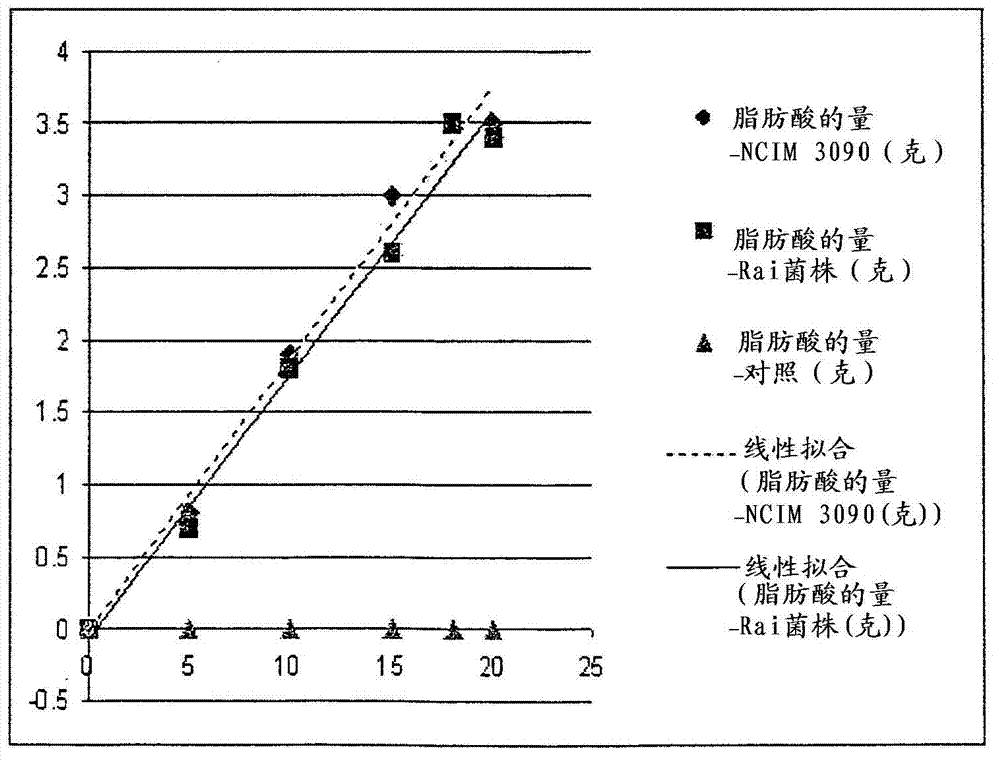

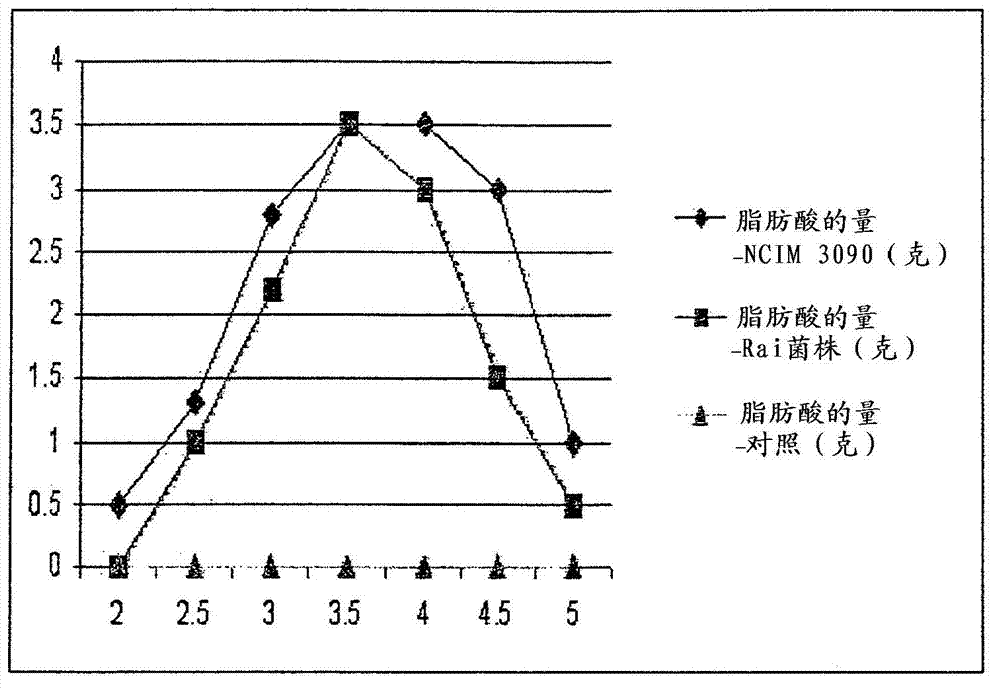

[0115] Example 1 Optimum Growth Conditions for Yeast Production of Fatty Acids Regarding Temperature, pH, Medium Composition and Dextrose Concentration

[0116] Experiments with growth conditions that maximize fatty acid production by yeast were performed with the aim of determining conditions that modulate biomass growth and enhance fatty acid synthesis and accumulation and / or secretion.

[0117] Two strains of S. cerevisiae were tested in parallel:

[0118] 1) National center for industrial microorganisms (NCIM) strain 3090,

[0119] (http: / / www.ncl-india.org / ncim / cataloguedetails.jsp?mid=29&category=yeast&ncimno=3090)

[0120] 2) Common baker's yeast strain

[0121] The strains were grown on Wickerham synthetic medium (Wickerham L J. 1951. Taxonomy of yeast. US Department of Agriculture, Technical Bulletin No. 1029.) the composition of which is given in Table 1, but with the carbon source changed as indicated.

[0122] Table 1

[0123]

[0124] Fermentation condition...

Embodiment 2

[0141] Example 2. Deletion of the FAA2 gene enhances fatty acid production in Saccharomyces cerevisiae

[0142] 2.0.0 method

[0143] Saccharomyces cerevisiae strain CEN-PK2 (MATa / MATa; ura3-52 / ura3-52; trpl-289 / trp1-289; leu2-3,112 / leu2-3,112; his3D1 / his3D1; The FAA2 gene in MAL2-8C / MAL2-8C; SUC2 / SUC2) was deleted and replaced with a 1.1 kbp URA3 marker gene (derived from Kluyveromyces marxii) to enable uracil synthesis. URA3 encodes orotidine 5-phosphate decarboxylase (ODCase), an enzyme involved in pyrimidine nucleotide synthesis.

[0144] Primer set 1 was designed to delete the FAA2 gene along the 150 bp upstream flank of the FAA2 gene and the 60 bp downstream flank of the FAA2 gene in the parental CEN-PK2 strain (hereinafter referred to as the WT strain). Primer set 3 (binding near the center of the FAA2 gene sequence) was used to amplify a ~1300 bp fragment of the FAA2 gene in order to detect the FAA2 gene in genomic DNA derived from the WT strain. Primers were design...

Embodiment 3

[0198] Example 3. Use of Candida tropicalis for the production of fatty acids suitable for diesel production

[0199] Candida tropicalis (DTU strain library) was cultured on the improved Wickerham synthetic medium with a specific carbon source, and the fatty acids in the growth medium and cells were extracted according to 2.0.0.

[0200] 3.0.0 When Candida tropicalis was grown on synthetic medium supplemented with glucose and the secreted fatty acids were extracted and analyzed by GC-MS, a total of 21 peaks were detected ( Figure 13 ). The most prominent peak corresponding to 35% of the total extracted fatty acids had a residence time of 28.84 minutes and was identified as hexadecanoic acid. The yield of saponifiable fatty acids after organic extraction was 7.5ml / 50 medium. The production of hexadecanoic acid was 50 ml / liter medium.

[0201] 3.0.1 When Candida tropicalis was grown on a synthetic medium (Table 5) supplemented with 5% glycerol and the secreted fatty acids we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com