Porous membrane composed of cellulose doped with 1,4-dihydroxy anthraquinone and bivalent copper ion and preparation method and application thereof

A technology of dihydroxyanthraquinone and divalent copper ions, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., to achieve good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The concrete steps of preparation are:

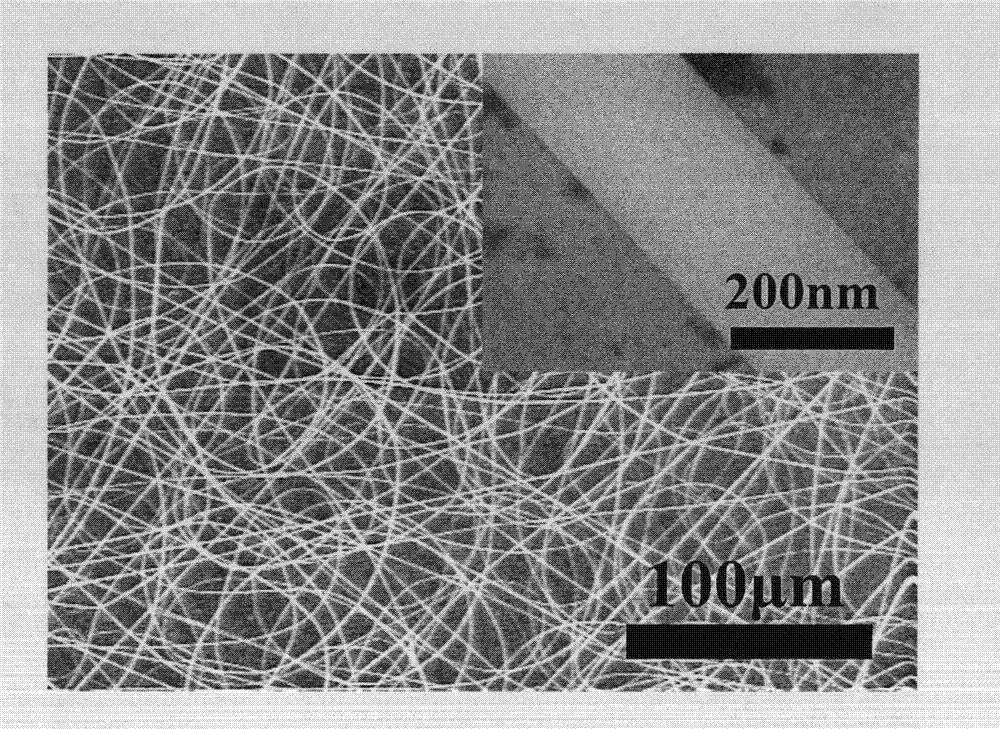

[0034] Step 1, first cellulose acetate, 1,4-dihydroxyanthraquinone, copper nitrate trihydrate and solvent are mixed according to the ratio of 7.5wt%: 0.1wt%: 0.22wt%: 92.18wt%; wherein, The solvent is a mixed solution of acetone and deionized water to obtain a spinning solution. Then the spinning solution was placed on the electrospinning machine for 3 minutes of electrospinning; wherein, the distance between the positive and negative electrodes during electrospinning was 10cm, the electrostatic voltage was 26kV, and the flow rate of the spinning solution was 0.001mL / s , the nanofibers were collected by a grounded aluminum plate to obtain a porous membrane composed of cellulose acetate nanofibers doped with 1,4-dihydroxyanthraquinone and divalent copper ions.

[0035] In step 2, the porous membrane composed of cellulose acetate nanofibers doped with 1,4-dihydroxyanthraquinone and divalent copper ions is soaked in sodium hydroxid...

Embodiment 2

[0037] The concrete steps of preparation are:

[0038] Step 1, first cellulose acetate, 1,4-dihydroxyanthraquinone, copper nitrate trihydrate and solvent are mixed according to the ratio of 7.8wt%: 0.1wt%: 0.21wt%: 91.89wt%; wherein, The solvent is a mixed solution of acetone and deionized water to obtain a spinning solution. Then the spinning solution is placed on the electrospinning machine for 3.5min electrospinning; wherein, the distance between the positive and negative electrodes during electrospinning is 10cm, the electrostatic voltage is 26kV, and the flow rate of the spinning solution is 0.001mL / s, The nanofibers were collected by a grounded aluminum plate to obtain a porous membrane composed of cellulose acetate nanofibers doped with 1,4-dihydroxyanthraquinone and divalent copper ions.

[0039] In step 2, the porous membrane composed of cellulose acetate nanofibers doped with 1,4-dihydroxyanthraquinone and divalent copper ions is soaked in sodium hydroxide solution...

Embodiment 3

[0041] The concrete steps of preparation are:

[0042] Step 1, first cellulose acetate, 1,4-dihydroxyanthraquinone, copper nitrate trihydrate and solvent are mixed according to the ratio of 8wt% by weight: 0.1wt%: 0.2wt%: 91.7wt%; wherein, the solvent A solution mixed with acetone and deionized water to obtain a spinning solution. Then the spinning solution is placed on the electrospinning machine for 4min electrospinning; wherein, the distance between the positive and negative electrodes during electrospinning is 10cm, the electrostatic voltage is 26kV, and the flow rate of the spinning solution is 0.001mL / s , the nanofibers were collected by a grounded aluminum plate to obtain a porous membrane composed of cellulose acetate nanofibers doped with 1,4-dihydroxyanthraquinone and divalent copper ions.

[0043] In step 2, the porous membrane composed of cellulose acetate nanofibers doped with 1,4-dihydroxyanthraquinone and divalent copper ions is soaked in sodium hydroxide solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com