A kind of solar cell preparation method

A technology for solar cells and silicon wafers, which is applied to circuits, electrical components, and final product manufacturing. The effect of edge leakage, reduction of silicon dangling bonds, and improvement of short-circuit current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

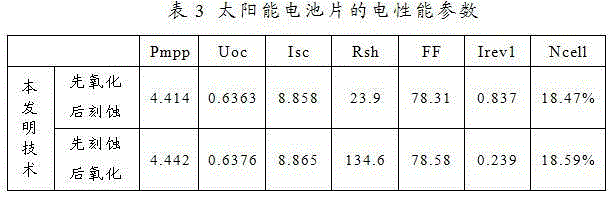

[0022] Select a single crystal silicon wafer; silicon wafer 1 undergoes a conventional cleaning process and texturing, puts silicon wafer 1 into a diffusion furnace, heats up to 810°C, and feeds large nitrogen (8L / min), small nitrogen (1.7L / min), oxygen (1L / min) for 12min, and after the temperature rises to 855°C, the diffusion junction advances for 7min; the diffused silicon wafer 1 is placed in 2% hydrofluoric acid, and the reaction time is 90s; the obtained silicon wafer 1 is placed again Put into the oxidation furnace, feed large nitrogen (7L / min), oxygen (1L / min), keep the temperature at 870°C for 5min; adopt PECVD process to make a silicon nitride film on the surface of silicon wafer 1 with a thickness of 85nm and a refractive index of 85nm. The ratio is 2.08; and then screen printing and sintering are used in sequence to obtain finished solar cells. Comparing the battery sheet obtained in Example 1 of the present invention with the battery sheet of the prior art, the r...

Embodiment 2

[0025] Select a quasi-single crystal silicon wafer; silicon wafer 1 undergoes a conventional cleaning process and texturing, puts silicon wafer 1 into a diffusion furnace, heats up to 785°C, and feeds large nitrogen (6.5L / min), small nitrogen (1L / min), oxygen (0.25L / min) diffused for 15min, and after the temperature was raised to 830°C, the diffusion junction was advanced for 15min; the diffused silicon wafer 1 was placed in 5% hydrofluoric acid, and the reaction time was 50s; the obtained silicon wafer 1 Put it into the oxidation furnace again, feed large nitrogen (7L / min), oxygen (0.25L / min), keep the temperature at 820°C, and the time is 10min; adopt the PECVD process to make a silicon nitride film on the surface of the silicon wafer 1. The thickness of the film is 75nm, and the refractive index is 2.13; then screen printing and sintering are used in sequence to obtain finished solar cells. Comparing the battery sheet obtained in Example 2 of the present invention with the...

Embodiment 3

[0028] Select single crystal silicon wafer; silicon wafer 1 undergoes conventional cleaning process and texturing, diffusion process: put the silicon wafer into a diffusion furnace, heat up to 800°C, and feed large nitrogen (7L / min), small nitrogen (1.5 L / min), oxygen (0.9L / min) to diffuse for 10 minutes, after the temperature rises to 845°C, the diffusion junction advances for 10 minutes; etching process: silicon wafer 1 is placed in 7% hydrofluoric acid, and the reaction time is 30s; oxidation process : put into the oxidation furnace, feed large nitrogen (7L / min), oxygen (0.6L / min), keep the temperature at 870°C, and the time is 8min; adopt the PECVD process to make a silicon nitride film on the surface of the silicon wafer 1 with a thickness of 80nm, the refractive index is 2.10; and then screen printing and sintering are used in sequence to obtain finished solar cells. Comparing the battery sheet obtained in Example 3 of the present invention with oxidation first and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com