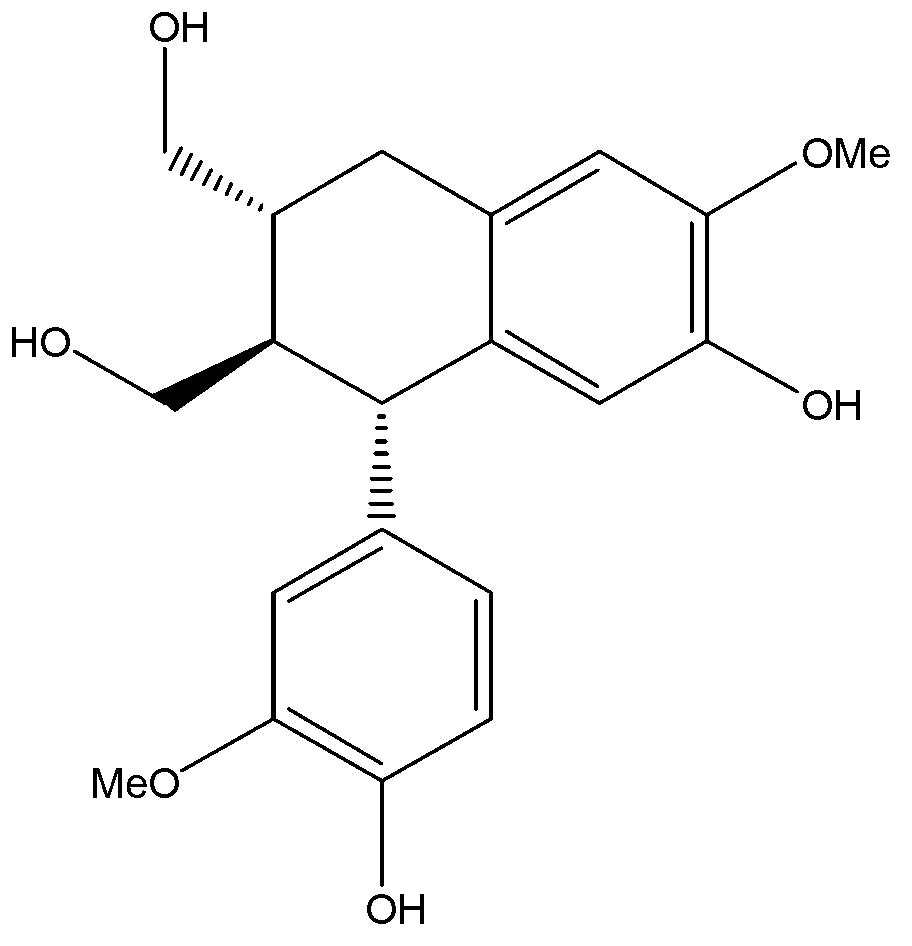

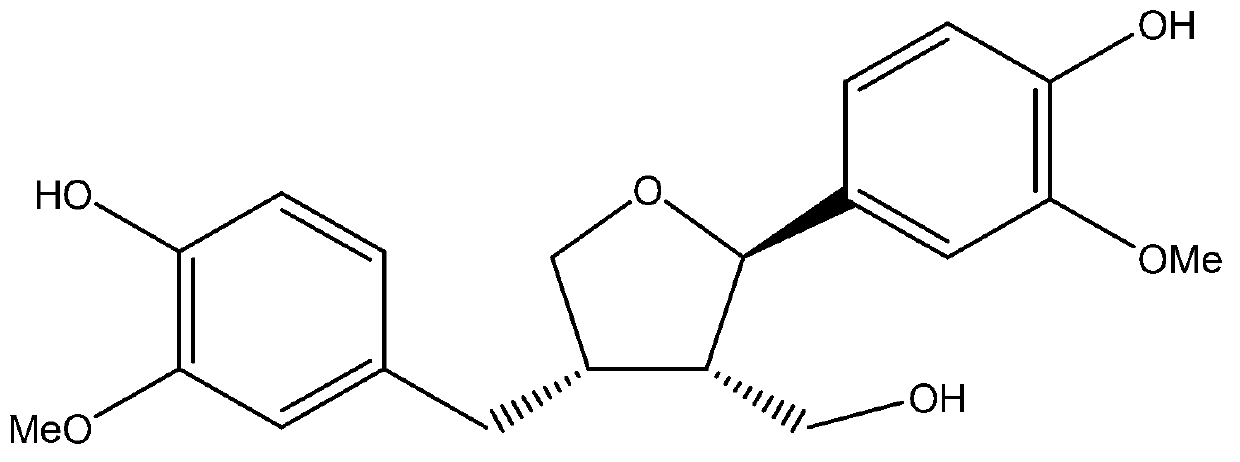

Method for separating and purifying (+)-isolariciresinol and (-)-lariciresinol from folium isatidis

A technology for larch resin alcohol and larch resin, which is applied in the field of medicine, can solve the problems of easy loss of target compounds, unfavorable environmental protection and health, and long process, and achieves the effects of few steps, simple operation and low reagent toxicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A method for rapidly and massively separating and purifying high-purity (+)-isolaricoresinol and (-)-larigoresinin from Folium chinensis is carried out according to the following process steps:

[0021] A. Enzymatic hydrolysis of homogenate crushing: add 5L water to 1kg of dried Folium Folium and carry out homogenate crushing for 5 minutes, adjust the pH of the slurry to 4.0 with hydrochloric acid, add cellulase to make the enzyme concentration 500U / mL, and then enzyme at 40°C Solution for 3h, filter, collect filtrate and filter residue.

[0022] B. Negative pressure cavitation enhanced extraction: add 17L ethanol to the above filter residue to carry out negative pressure cavitation enhanced extraction, the extraction temperature is 45°C, the extraction pressure is -0.06MPa, extract 2 times, each time 50min, combine the extract and step A The obtained filtrate was recovered under reduced pressure to remove the solvent to obtain 170 g of Daqingye extract.

[0023] C. Re...

Embodiment 2

[0027] A method for rapidly and massively separating and purifying high-purity (+)-isolaricoresinol and (-)-larigoresinin from Folium chinensis is carried out according to the following process steps:

[0028] A. Enzyme hydrolysis of homogenate crushing: add 7L water to 1kg of dry Folium baccatum and carry out homogenate crushing for 8 minutes, adjust the pH of the slurry to 5.0 with glacial acetic acid, add a compound enzyme of cellulase and pectinase to make the concentration of cellulase 350U / mL, the concentration of pectinase is 200U / mL, then enzymatically hydrolyze at 45°C for 2h, filter, and collect the filtrate and filter residue.

[0029] B. Negative pressure cavitation enhanced extraction: add 10L80% ethanol to the above filter residue to carry out negative pressure cavitation enhanced extraction, the extraction temperature is 35°C, the extraction pressure is -0.075MPa, extract 3 times, each time for 30min, combine the extract and the steps A obtained filtrate was re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com