Preparation method of halogen-free flame retardant polyurethane-cage type silsesquioxane nanocomposite

A technology of nanocomposite materials and silsesquioxane, which is applied in the field of preparation of nanocomposite materials, can solve the problem that modified polyurethane cannot obtain flame retardant properties, the flame retardancy has not been substantially changed, and cannot be used in the field of flame retardancy and other problems, to achieve the effect of being suitable for large-scale industrial production, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

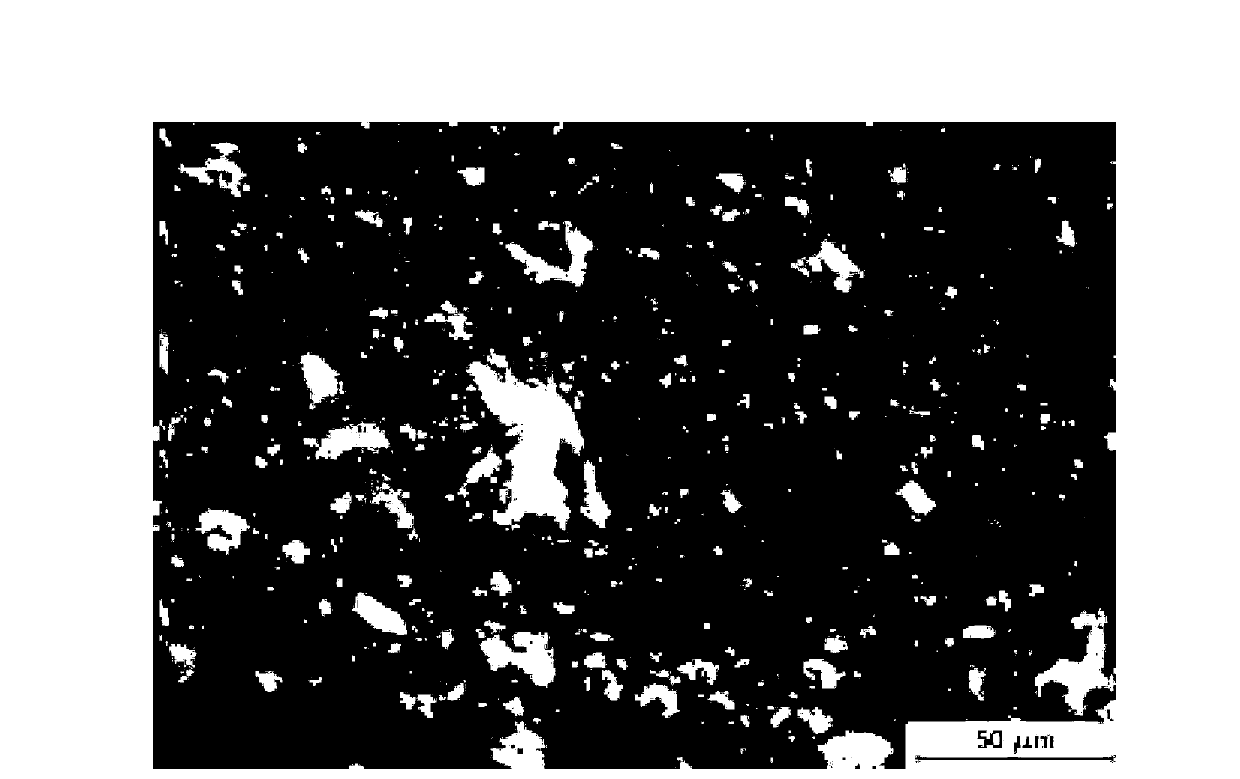

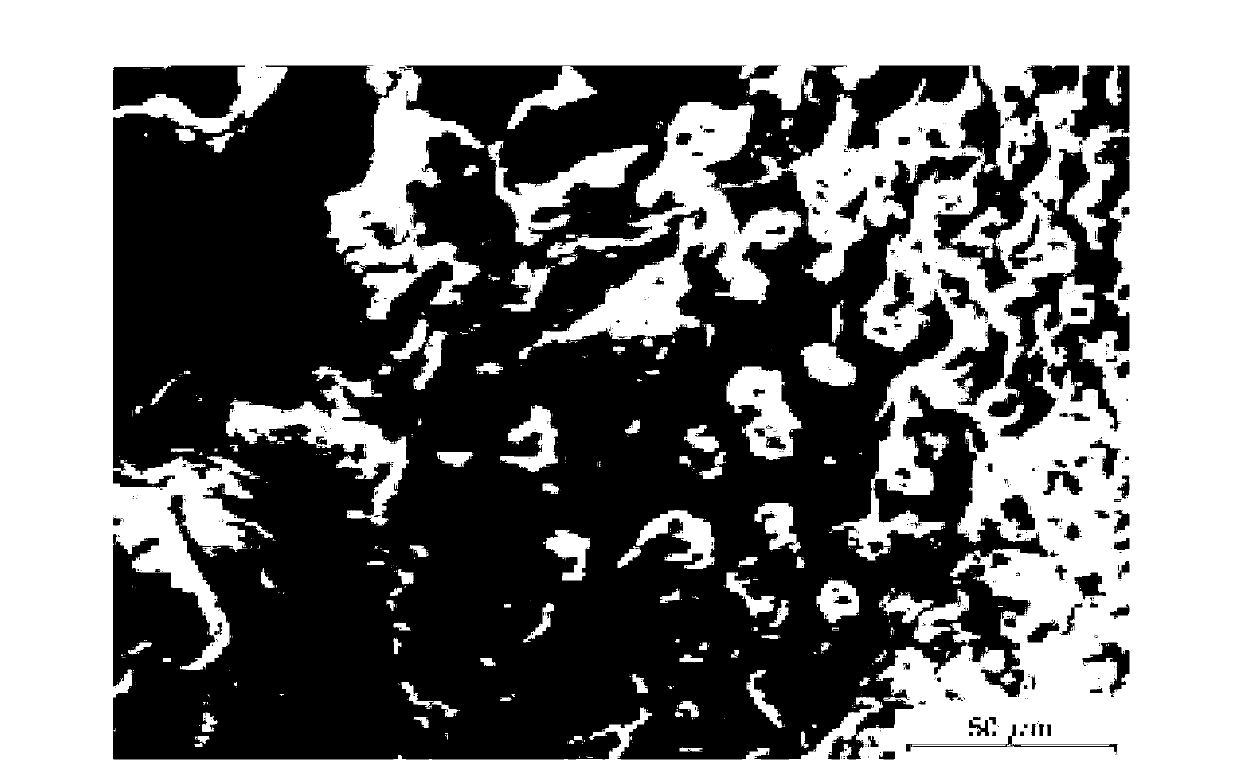

Image

Examples

Embodiment 1

[0020] The concrete steps of preparation are:

[0021] Step 1, first add diphenylmethane diisocyanate to the nanocage silsesquioxane N,N-dimethylformamide solution with a concentration of 10%, and stir at 70°C for 12h; among them, diphenylmethane The weight ratio of methane diisocyanate to nanocage silsesquioxane in N,N-dimethylformamide solution is 1:11, and the particle size of nanocage silsesquioxane is The diameter is 1nm, which is nano-phenyl clathrate silsesquioxane, and the solution of modified clathrate silsesquioxane is obtained. Then the modified clathrate silsesquioxane solution was dried at 70°C, and after the solvent N,N-dimethylformamide volatilized, it was ground and passed through a 1000-mesh sieve to obtain the modified clathrate silsesquioxane Silesquioxane powder.

[0022] Step 2, first mix polytetrahydrofuran ether glycol, modified clathrate silsesquioxane powder and N,N-dimethylformamide in a weight ratio of 98:15:250, and stir at 50°C 1h, a mixed solut...

Embodiment 2

[0025] The concrete steps of preparation are:

[0026] Step 1, first add diphenylmethane diisocyanate to the nanocage silsesquioxane N,N-dimethylformamide solution with a concentration of 13%, and stir at 75°C for 11 hours; among them, diphenylmethane The weight ratio of methane diisocyanate to nanocage silsesquioxane in N,N-dimethylformamide solution is 2:10.5, and the particle size of nanocage silsesquioxane is The diameter is 1nm, which is nano-phenyl clathrate silsesquioxane, and the solution of modified clathrate silsesquioxane is obtained. Then the modified clathrate silsesquioxane solution was dried at 75°C, and after the solvent N,N-dimethylformamide volatilized, it was ground and passed through a 1000-mesh sieve to obtain the modified clathrate silsesquioxane Silesquioxane powder.

[0027] Step 2, first mix polytetrahydrofuran ether glycol, modified clathrate silsesquioxane powder and N,N-dimethylformamide in a weight ratio of 99:11:288, and stir at 53°C After 0.8h...

Embodiment 3

[0030] The concrete steps of preparation are:

[0031]Step 1, first add diphenylmethane diisocyanate to the nanocage silsesquioxane N,N-dimethylformamide solution with a concentration of 15%, and stir at 80°C for 10h; among them, diphenylmethane The weight ratio of methane diisocyanate to nanocage silsesquioxane in N,N-dimethylformamide solution is 3:10, and the particle size of nanocage silsesquioxane is The diameter is 1.5nm, which is nano-phenyl clathrate silsesquioxane, and the solution of modified clathrate silsesquioxane is obtained. Then the modified clathrate silsesquioxane solution was dried at 80°C, and after the solvent N,N-dimethylformamide volatilized, it was ground and passed through a 1000-mesh sieve to obtain the modified clathrate silsesquioxane Silesquioxane powder.

[0032] Step 2, first mix polytetrahydrofuran ether glycol, modified clathrate silsesquioxane powder and N,N-dimethylformamide in a weight ratio of 100:8:325, and stir at 55°C 0.6h, a mixed so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com