Epichloro-hydrin rubber and polyvinyl chloride blending-type thermoplastic elastomer inner tube material and preparation method thereof

A thermoplastic elastomer and polyvinyl chloride technology, which is applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as no and no one, and reduce material loss, increase the scope of use, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1, a method for preparing a thermoplastic elastomer inner tube material blended with epichloride rubber and polyvinyl chloride, the specific steps are as follows:

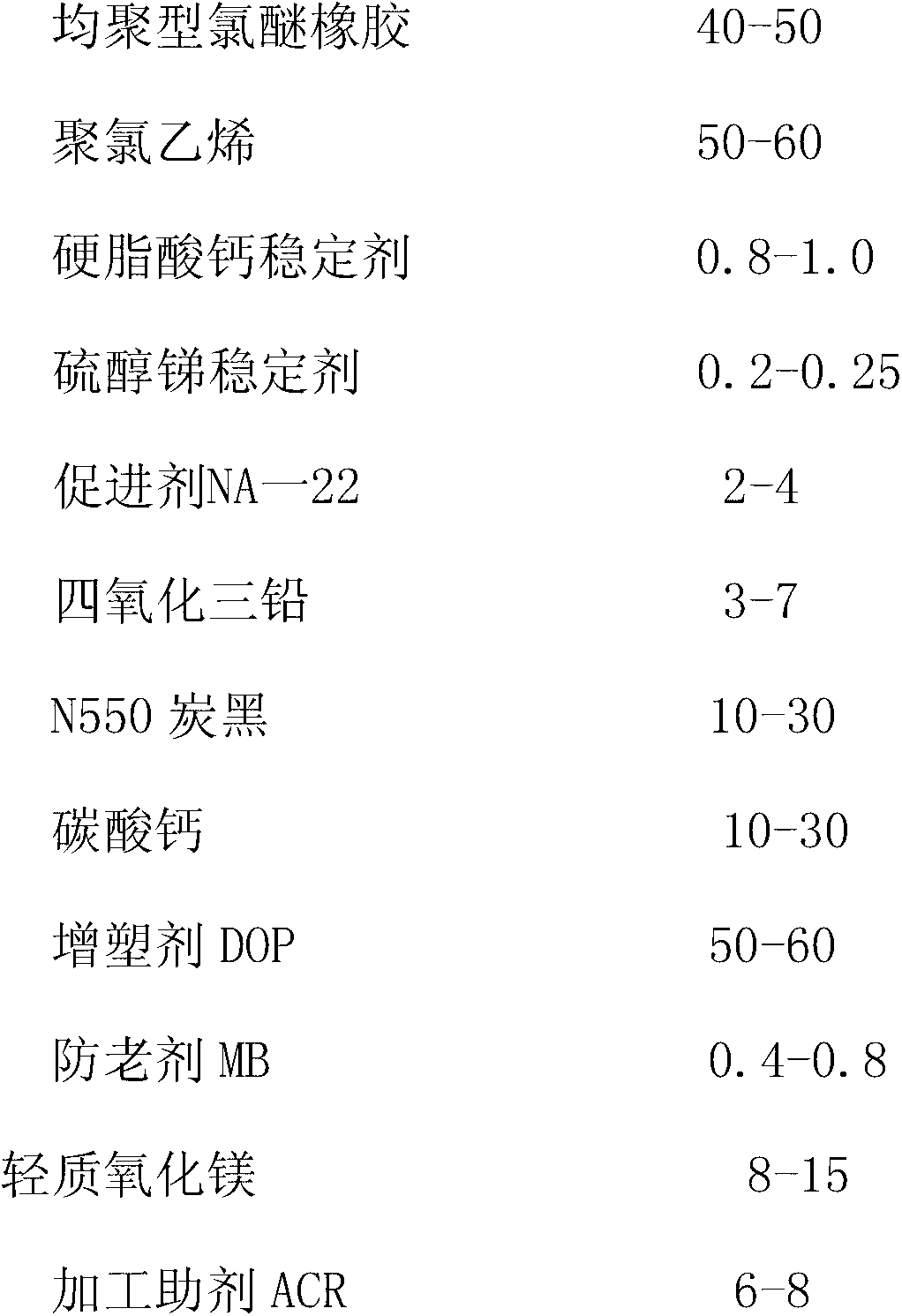

[0029] (1) Prepare the following component materials in parts by mass: 40 parts of homopolychloroether rubber, 60 parts of polyvinyl chloride, 1.0 part of calcium stearate stabilizer, 0.25 part of mercaptan antimony stabilizer, 2 parts of 1.2-substance Ethylthiourea, 4 parts of trilead tetraoxide, 10 parts of N660 carbon black, 30 parts of calcium carbonate, 60 parts of dioctyl phthalate, 0.4 parts of 2-mercaptobenzimidazole, 15 parts of light magnesium oxide, 8 parts Parts of processing aid ACR; wherein the processing aid ACR is a copolymer of acrylate and methacrylate;

[0030] (2) Stir and heat 60 parts of polyvinyl chloride with a high-speed mixing mixer to a temperature of 100±5°C, and then gradually add 60 parts by mass of plasticizer DOP. When adding plasticizer DOP, keep the temperature of...

Embodiment 2

[0032] Embodiment 2, a preparation method of a thermoplastic elastomer inner tube material blended with epichloride rubber and polyvinyl chloride, the specific steps are as follows:

[0033] (1) Prepare the following component materials in parts by mass: 45 parts of homopolychloroether rubber, 55 parts of polyvinyl chloride, 0.9 part of calcium stearate stabilizer, 0.23 part of mercaptan antimony stabilizer, 3 parts of 2-sulfur Alcohol-based imidazoline, 5.5 parts of trilead tetraoxide, 20 parts of N660 carbon black, 20 parts of calcium carbonate, 55 parts of dioctyl phthalate, 0.6 parts of 2-mercaptobenzimidazole, 12 parts of light magnesium oxide, 7 Parts of processing aid ACR; wherein the processing aid ACR is a copolymer of acrylate and methacrylate;

[0034](2) Stir and heat 55 parts of polyvinyl chloride with a mixing mixer to a temperature of 100±5°C, then gradually add 55 parts by mass of plasticizer DOP, when adding plasticizer DOP, keep the temperature of the materia...

Embodiment 3

[0036] Embodiment 3, a method for preparing a thermoplastic elastomer inner tube material blended with epichloride rubber and polyvinyl chloride, the specific steps are as follows:

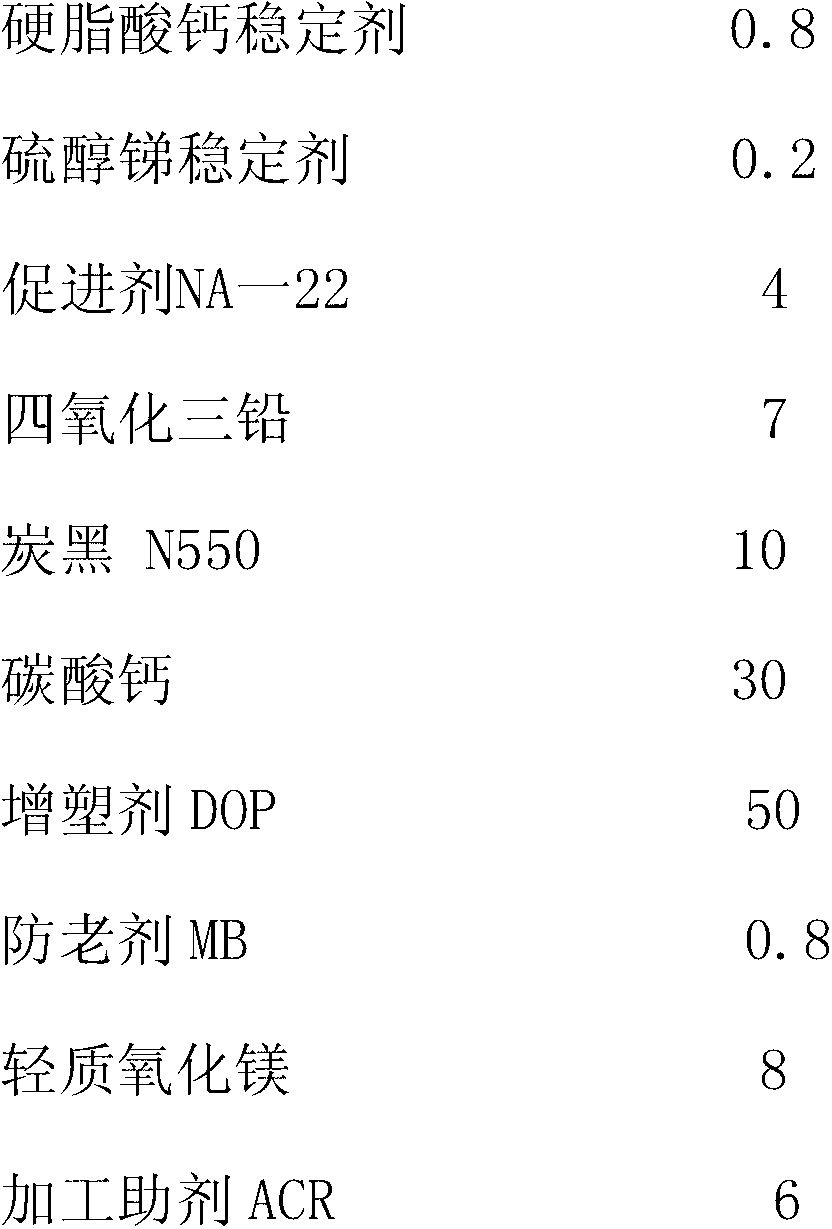

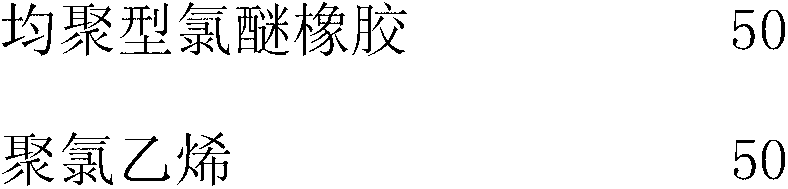

[0037] (1) Prepare the following component materials in parts by mass: 50 parts of homopolychloroether rubber, 50 parts of polyvinyl chloride, 0.8 part of calcium stearate stabilizer, 0.2 part of mercaptan antimony stabilizer, 4 parts of 1.2-substance Ethylthiourea, 7 parts of trilead tetraoxide, 30 parts of N660 carbon black, 10 parts of calcium carbonate, 50 parts of dioctyl phthalate, 0.8 parts of 2-mercaptobenzimidazole, 8 parts of light magnesium oxide, 6 parts Parts of processing aid ACR; wherein the processing aid ACR is a copolymer of acrylate and methacrylate;

[0038] (2) Stir and heat 50 parts of polyvinyl chloride with a high-speed mixing mixer to a temperature of 100±5°C, and then gradually add 50 parts by mass of plasticizer DOP. When adding plasticizer DOP, keep the temperature of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com