Method for producing stock seeds of enoki mushrooms

A technology of white Flammulina velutipes and production methods, applied in botany equipment and methods, horticulture, applications, etc., can solve the problems of mycelium not easy to decompose, low content of mycelium in strains, high production cost, etc., and achieve easy control of process conditions, The effect of strong vitality and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

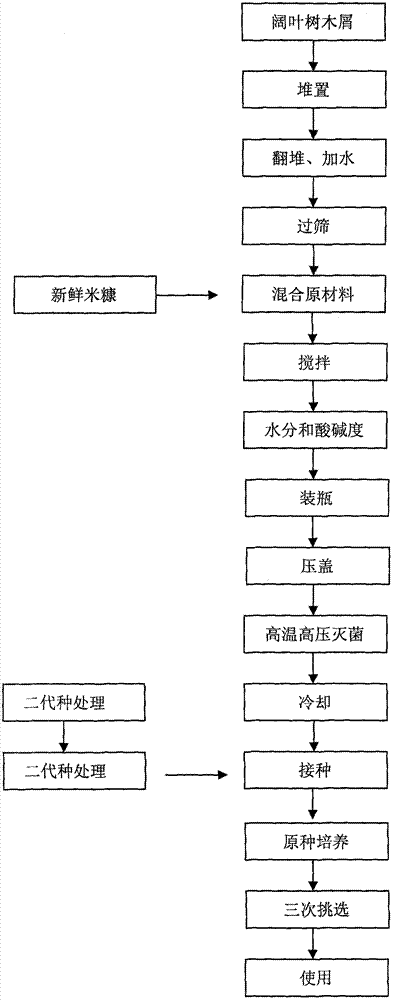

Method used

Image

Examples

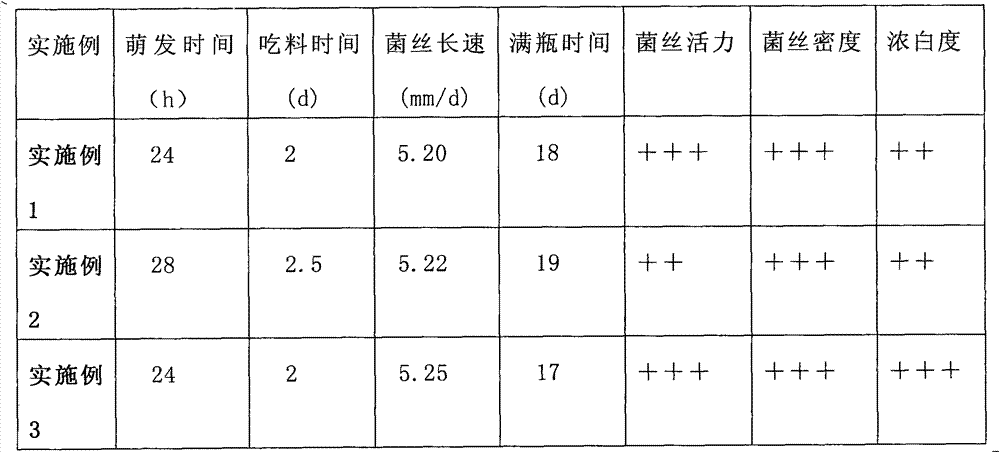

Embodiment 1

[0017] 1) The weight percent of each raw material in the culture medium is: sawdust 60%, rice bran 34%, cottonseed hull 5%, light calcium carbonate 1%;

[0018] 2) Material preparation: The wood chips used are poplar and willow broad-leaved wood chips. During the stacking process of the wood chips, water should be added to the stack for 1-2 months, and the stack should be turned over and added with water for 1-2 months. Once, water should be replenished each time the pile is turned, so that the water content of the sawdust pile is controlled at 60-65wt%; sieve before use, and the particle size of the sawdust is 2-4mm;

[0019] Before preparing materials, use an infrared moisture analyzer to measure the water content of wood chips and rice bran (the amount of cottonseed hulls and light calcium carbonate is small, and the water content is negligible), and calculate the amount of raw materials added according to the water content; first add wood chips to the stirring pot, Then ad...

Embodiment 2

[0027] 1) The percentage by weight of each raw material in the culture medium is: wood chips 50%, rice bran 38%, cottonseed hulls 10%, light calcium carbonate 2%;

[0028] 2) Material preparation: The wood chips used are poplar, willow and elm broad-leaved wood chips. During the stacking process of the wood chips, water should be added to the stack for 1-2 months, and the stack should be turned over and then watered for 1-2 months. Turn the pile at least twice, and replenish water for each turn, so that the water content of the sawdust pile is controlled at 60-65wt%; sieve before use, and the particle size of the sawdust is 2-4mm;

[0029] Before preparing materials, use an infrared moisture analyzer to measure the water content of wood chips and rice bran, and calculate the amount of raw materials added according to the water content; first add wood chips to the stirring pot, then add rice bran, cottonseed hulls and light calcium carbonate and stir for 20 minutes to make the c...

Embodiment 3

[0037] 1) The weight percent of each raw material in the culture medium is: sawdust 56%, rice bran 35%, cottonseed hull 8%, light calcium carbonate 1%;

[0038] 2) Material preparation: The wood chips used are poplar and willow broad-leaved wood chips. During the stacking process of the wood chips, water should be added to the stack for 1-2 months, and the stack should be turned over and added with water for 1-2 months. Once, water should be replenished each time the pile is turned, so that the water content of the sawdust pile is controlled at 60-65wt%; sieve before use, and the particle size of the sawdust is 2-4mm;

[0039] Before preparing materials, use an infrared moisture analyzer to measure the water content of wood chips and rice bran, and calculate the amount of raw materials added according to the water content; first add wood chips to the stirring pot, then add rice bran, cottonseed hulls and light calcium carbonate and stir for 20 minutes to make the culture medium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com