Method for synthesizing carbide/porous graphitized carbon nano compound through one-step method

A technology of porous graphitic carbon and nanocomposite, applied in the fields of carbon compounds, chemical instruments and methods, nanotechnology, etc., can solve the problems of small specific surface area, large particle size, uneven distribution of tungsten carbide, etc. The effect of small size and cheap carbon source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

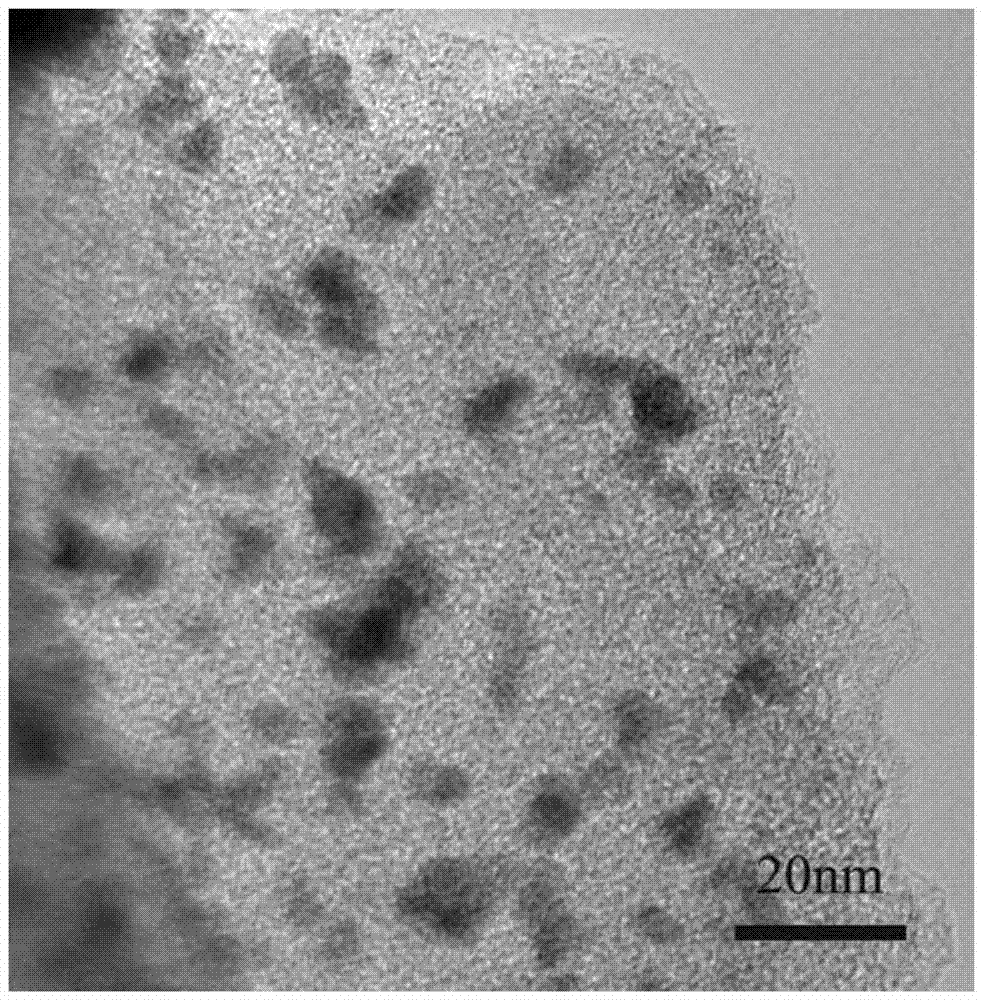

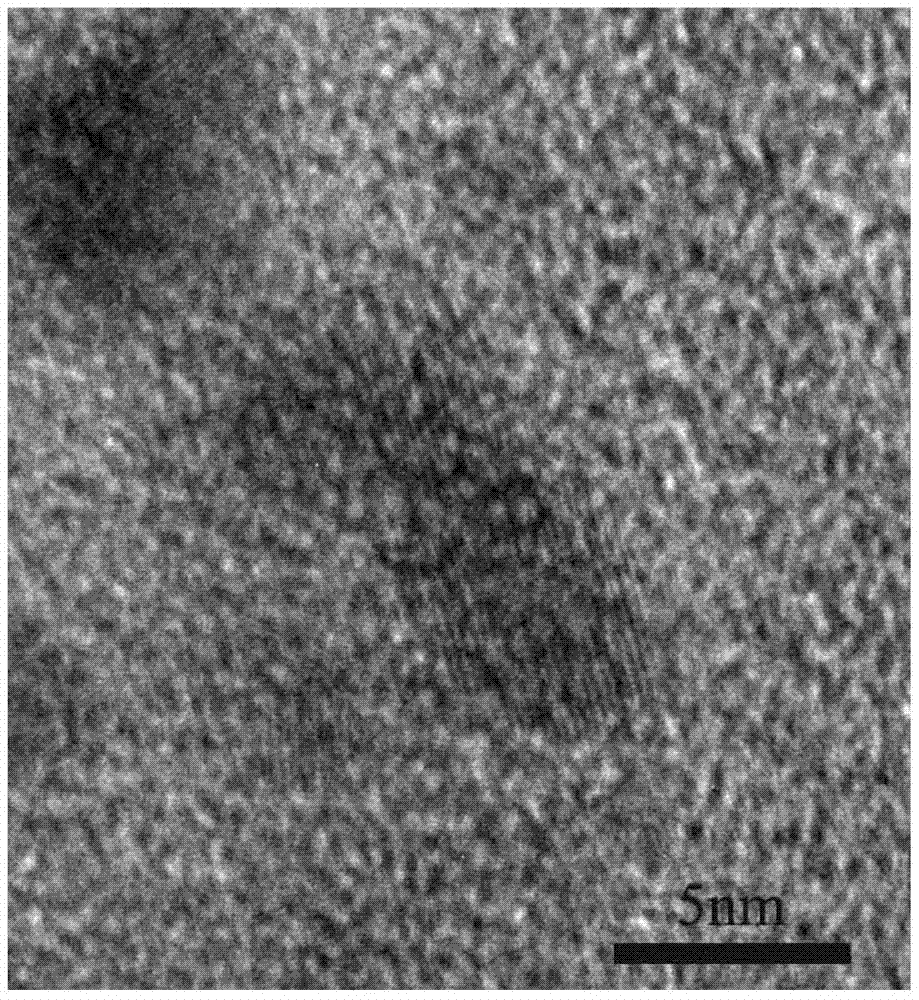

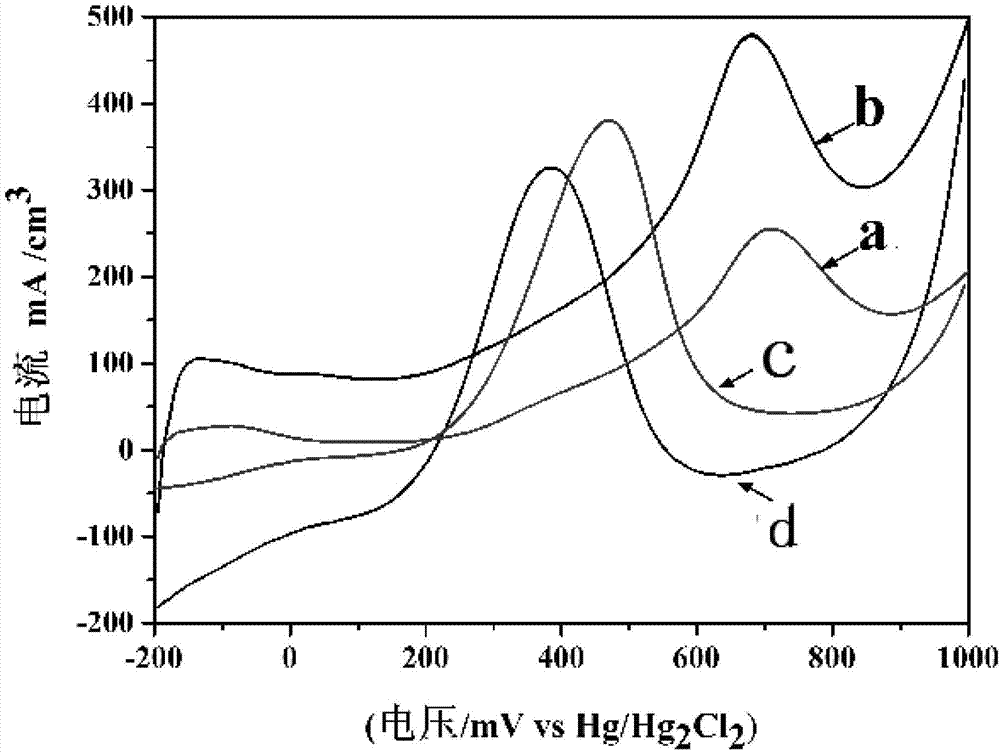

[0009] Specific embodiment one: the method for synthesizing carbide / porous graphite carbon nanocomposites in one step in this embodiment is completed by the following steps: one, the carbon source and transition metal salts are dissolved in the mass ratio of 10:2 In solvent, then add pore forming agent, then add graphitization catalyst, dry, obtain precursor; Wherein the mass volume ratio of carbon source and solvent is 1: (5~30), the mass volume ratio of carbon source and pore forming agent is 1: (1 ~ 10), the mass ratio of carbon source and graphite catalyst is 1: (0.5 ~ 5), wherein the transition metal salts are tungsten source, molybdenum source or vanadium source; 2. Under the condition of inert gas protection, From room temperature to 500-1100°C, the temperature rise rate is 2-20°C / min, and then heat-treat the precursor in step 1 for 0.5-10 hours to obtain the pre-product; 3. Grind the pre-product obtained in step 2, and then carry out Acid treatment, and then washed wit...

specific Embodiment approach 2

[0011] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the carbon source in step one is the extract of crops, high molecular polymer or shell extract, wherein the extract of crops is glucose, sucrose, citric acid , sucrose, fructose, maltose, oxalic acid, tartaric acid or starch; the polymer is one of polystyrene, polyacrylamide, polyfurfuryl alcohol, polyimide, polyurethane, polyglucosamine, polyvinyl acid methyl ester and polyaniline or a mixture of several of them in any ratio; the shell extract is chitosan or chitin. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0012] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the tungsten source in step one is H 2 W 6 o 19 、H 3 PW 12 o 40 、H 3 SiW 12 o 40 、H 4 W 10 o 32 , (NH 4 ) 6 W 7 o 24 、Na 2 WO 4 、Na 2 W 6 o 19 , WCl 6 、Na 3 PW 12 o 40 、Na 3 SiW 12 o 40 、Na 4 W 10 o 32 、K 2 W 6 o 19 、K 3 PW 12 o 40 、K 3 SiW 12 o 40 or K 4 W 10 o 32 ;Molybdenum source is H 2 Mo 6 o 19 、H 3 PMo 12 o 40 、H 3 SiMo 12 o 40 、H 4 Mo 10 o 32 , (NH 4 ) 6 Mo 7 o 24 、Na 2 MoO 4 、Na 2 Mo 6 o 19 、Na 3 PMo 12 o 40 、Na 3 SiMo 12 o 40 、Na 4 Mo 10 o 32 、K 2 Mo 6 o 19 、K 3 PMo 12 o 40 、K 3 SiMo 12 o 40 or K 4 Mo 10 o 32 ; Vanadium source is: HVO 3 、H 3 VO 4 、H 4 V 2 o 7 、H 3 V 3 o 9 、NaVO 3 , NH 4 VO 3 , Na 3 VO 4 or (NH 4 ) 2 V 6 o 16 . Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com