Preparation method for low-dielectric halogen-free flame retardant glass fiber pre-impregnation material

A technology of flame-retardant glass fiber and prepreg, which is applied in the field of composite materials, can solve problems such as high dielectric constant and unsatisfactory production process, and achieve the effect of improving flame-retardant performance and low water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

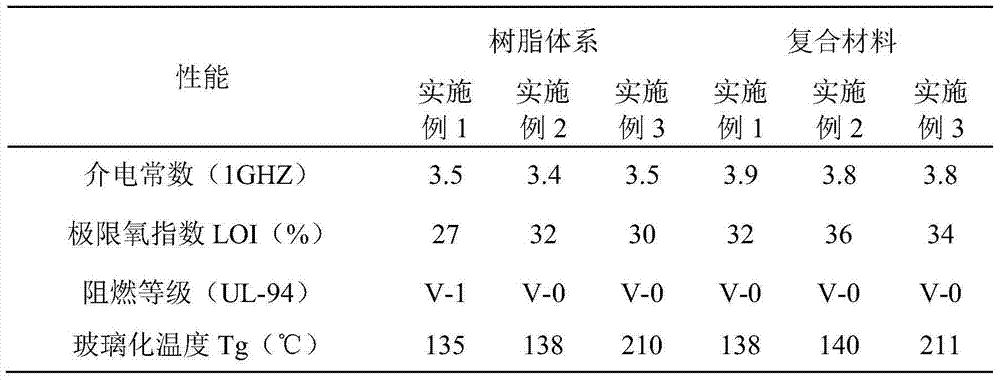

[0016] Weigh 2000g liquid novolak epoxy resin, 500g DOPO and 2g triphenylphosphorus catalyst respectively, place in the reactor, under nitrogen protection, react at 160 ℃ for 3 hours, then add 100g double-terminated hydroxyl polyphenylene ether (number average molecular weight 2000, GPC test), continue to react for 1h, then add 3903g of bisphenol A glycidyl ether and mix, cool down to 120°C, add 500g of dicyandiamide curing agent, stir evenly and vacuum degassing, and prepare a pre-prepared compound with a phosphorus content of 1.0wt%. The resin system used for impregnation is prepared according to the curing process of 130°C / 2h+150°C / 2h to prepare cast body specimens. The adhesive film of the above resin system is combined with glass fiber to make a prepreg, and then laminated to make a composite material. The dielectric constant, limiting oxygen index, flame retardant grade and glass transition temperature of the resin system and the composite sheet were tested respectively....

Embodiment 2

[0018] Weigh 2000g of bisphenol A glycidyl ether, 900g of DOPO and 10g of benzyl triphenylphosphine bromide catalyst respectively, place them in a reaction kettle, and react at 140°C for 4.5 hours under the protection of nitrogen, then add 300g of double-terminated hydroxyl polyphenylene Ether (number-average molecular weight 1800, GPC test), continue to react for 2 hours, then add 1370g of liquid novolak epoxy to mix, cool down to 120°C, add 458g of dicyandiamide curing agent, stir evenly and vacuum defoam to obtain a phosphorus content of 2.5wt % resin system for prepreg, according to the curing process of 130 ℃ / 2h + 150 ℃ / 2h, to prepare cast body samples. The adhesive film of the above resin system is combined with glass fiber to make a prepreg, and then laminated to make a composite material. The dielectric constant, limiting oxygen index, flame retardant grade and glass transition temperature of the resin system and the composite sheet were tested respectively. The re...

Embodiment 3

[0020] Weigh 2000g of bisphenol A glycidyl ether, 820g of DOPO and 40g of tetramethylammonium hydroxide catalyst respectively, place in a reaction kettle, under the protection of nitrogen, react at 120°C for 6 hours, then add 200g of double-ended hydroxyl polyphenylene ether ( Number average molecular weight 1700, GPC test), continue to react for 3 hours, then add 2020g trifunctional glycidylamine epoxy resin and mix, cool down to 120°C, add 730gDDS curing agent, stir evenly and vacuum degassing, the obtained phosphorus content is 2.0wt % resin system for prepreg, according to the curing process of 130 ℃ / 2h + 180 ℃ / 2h + 200 ℃ / 1h, to prepare cast body samples. The adhesive film of the above resin system is combined with glass fiber to make a prepreg, and then laminated to make a composite material. The dielectric constant, limiting oxygen index, flame retardant grade and glass transition temperature of the resin system and the composite sheet were tested respectively. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com