Normal-temperature chromophilous recycled polyester filament yarn and preparation method thereof

A polyester filament, atmospheric dyeing technology, applied in the manufacture of rayon, single-component polyester rayon, chemical characteristics of fibers, etc. Continuous industrial production and other issues, to achieve the effect of promoting development and utilization, good market prospects, and reducing economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

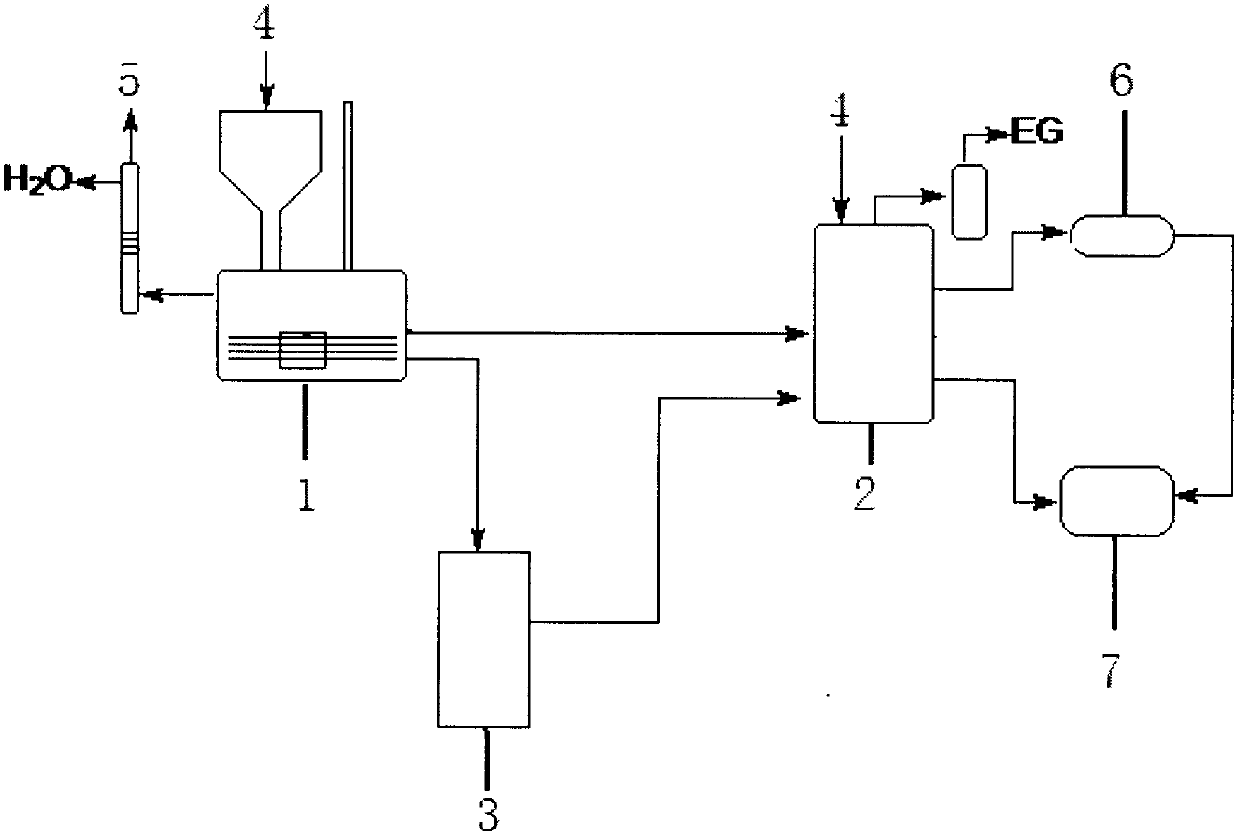

[0041] in such as figure 1 Put 10kg of polyester bottle flakes, 3kg of ethylene glycol, and n-butyl peptide acid accounting for 3‰ of polyester waste into the depolymerization kettle 1 shown in the reaction flow chart, and keep warm and pressurized at 250°C under a pressure of 3kg. Carry out depolymerization reaction in 3 hours;

[0042] After the depolymerization is completed, 5% of the depolymerization product is divided into the low-temperature reactor 3, and 5% of nano-MMT and 5% of polyethylene oxide are added to react at 200° C. for 1 hour, and the reaction is completed and passed into the polymerization reactor 2;

[0043] In the polymerization kettle 2, the depolymerization product in the depolymerization kettle 1 was introduced, and at the same time, 1% of adipic acid, 7% of isophthalic acid and 200ppm of stabilizer trimethyl phosphate were added, and 5% of low temperature The product in the reaction kettle 3, raise the temperature to 235°C and vacuumize for pre-cond...

Embodiment 2

[0045] in such as figure 1 Put 10kg of polyester bottle flakes, 5kg of ethylene glycol, and ethylene-based alumina accounting for 5‰ of polyester waste into the depolymerization kettle 1 shown in the reaction flow chart, and keep warm and pressurized at 260°C under a pressure of 2kg. Carry out depolymerization reaction in 2 hours;

[0046] After depolymerization, divide 10% of the depolymerization product into the low-temperature reactor 3 and add 1% nano-MMT to react at 150° C. for 12 hours, and pass it into the polymerization kettle 2 after the reaction is completed;

[0047] The depolymerization product in the depolymerization kettle 1 is passed into the polymerization kettle 2, and 3% of adipic acid, 4% of isophthalic acid and 50 ppm of stabilizer triphenyl phosphite are added simultaneously, and another 20% of For the product in the low-temperature reactor 3, raise the temperature to 260°C and vacuumize for pre-condensation for 30 minutes. When the vacuum degree reaches be...

Embodiment 3

[0049] in such as figure 1 10kg of polyester bottle flakes, 5kg of ethylene glycol, and ethylene glycol antimony accounting for 5‰ of polyester waste are put into the depolymerization kettle 1 as shown in the reaction flow chart. Hours for depolymerization reaction;

[0050] After depolymerization, divide 10% of the depolymerization product into the low-temperature reactor 3 and add 1% nano-MMT to react at 150° C. for 12 hours, and pass it into the polymerization kettle 2 after the reaction is completed;

[0051] The depolymerization product in the depolymerization kettle 1 is passed into the polymerization kettle 2, and 3% of adipic acid, 4% of isophthalic acid and 50 ppm of stabilizer trimethyl phosphate are added at the same time, and 20% of low temperature The product in the reaction kettle 3, raise the temperature to 260°C and vacuumize for pre-condensation, the time is 30min, when the vacuum reaches below 100Pa, raise the temperature to 280°C for polycondensation; Spin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com