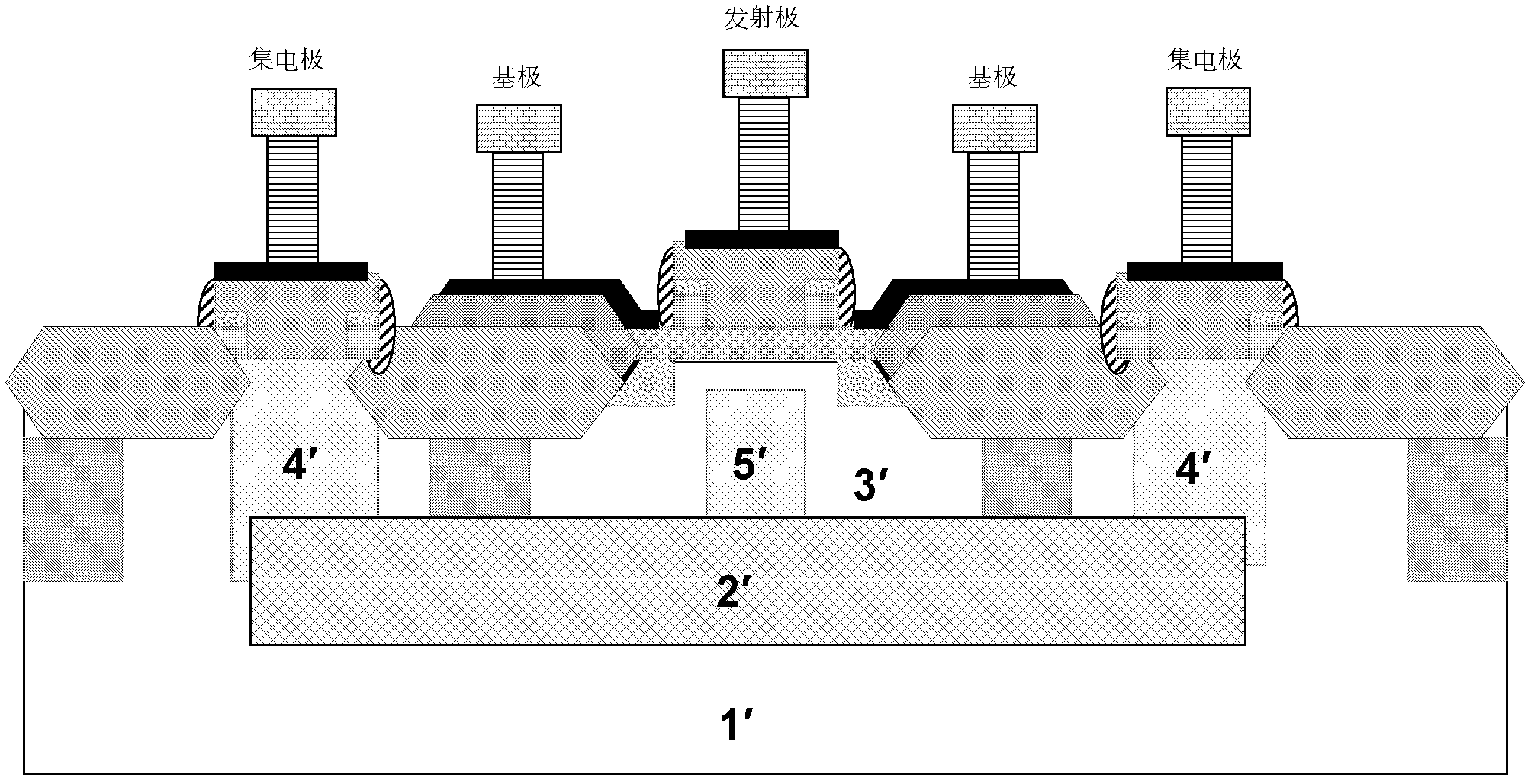

Germanium-silicon heterojunction bipolar transistor (HBT) single tube structure, manufacture method thereof and germanium-silicon HBT multi-finger structure

A single-tube structure, silicon germanium technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of large active area size, high doping concentration, large devices, etc., to reduce collector resistance, The effect of large output power and power gain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

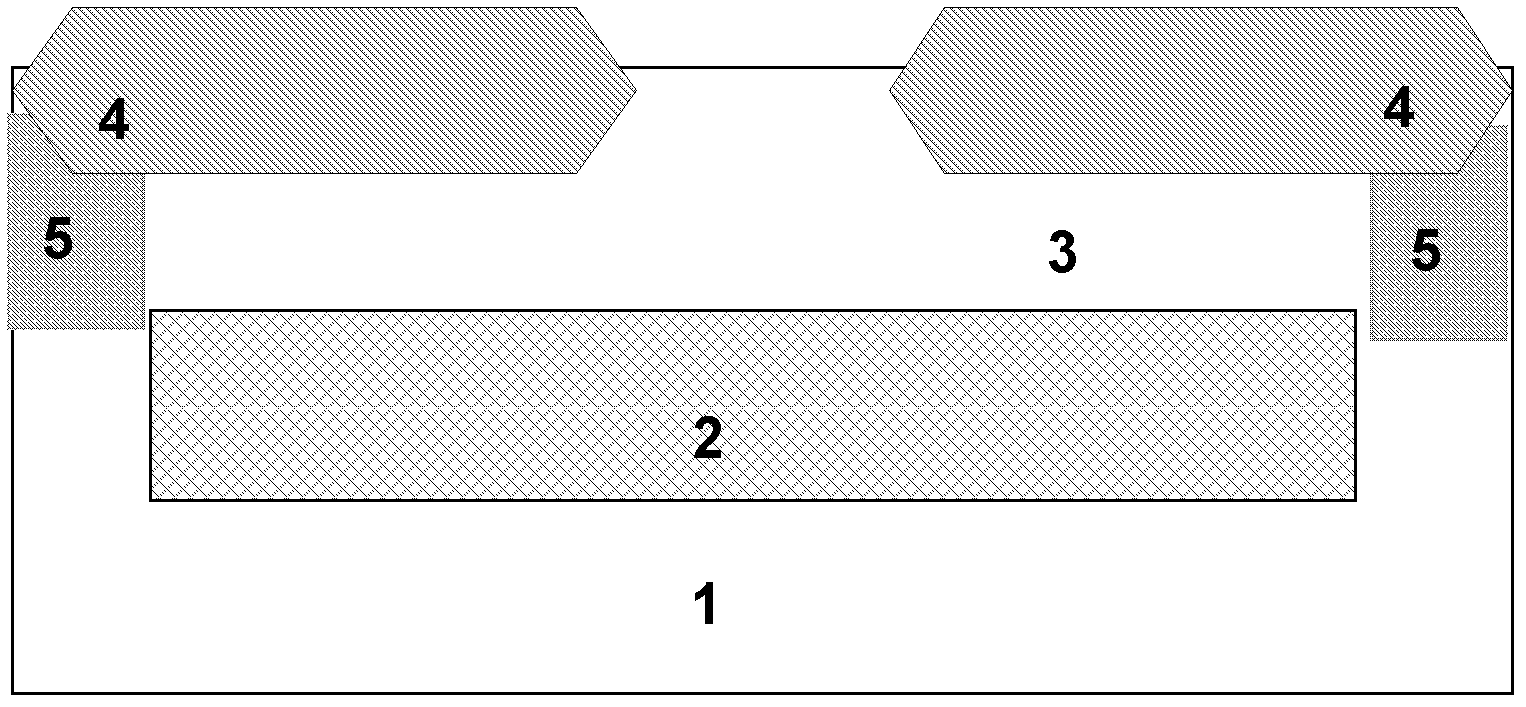

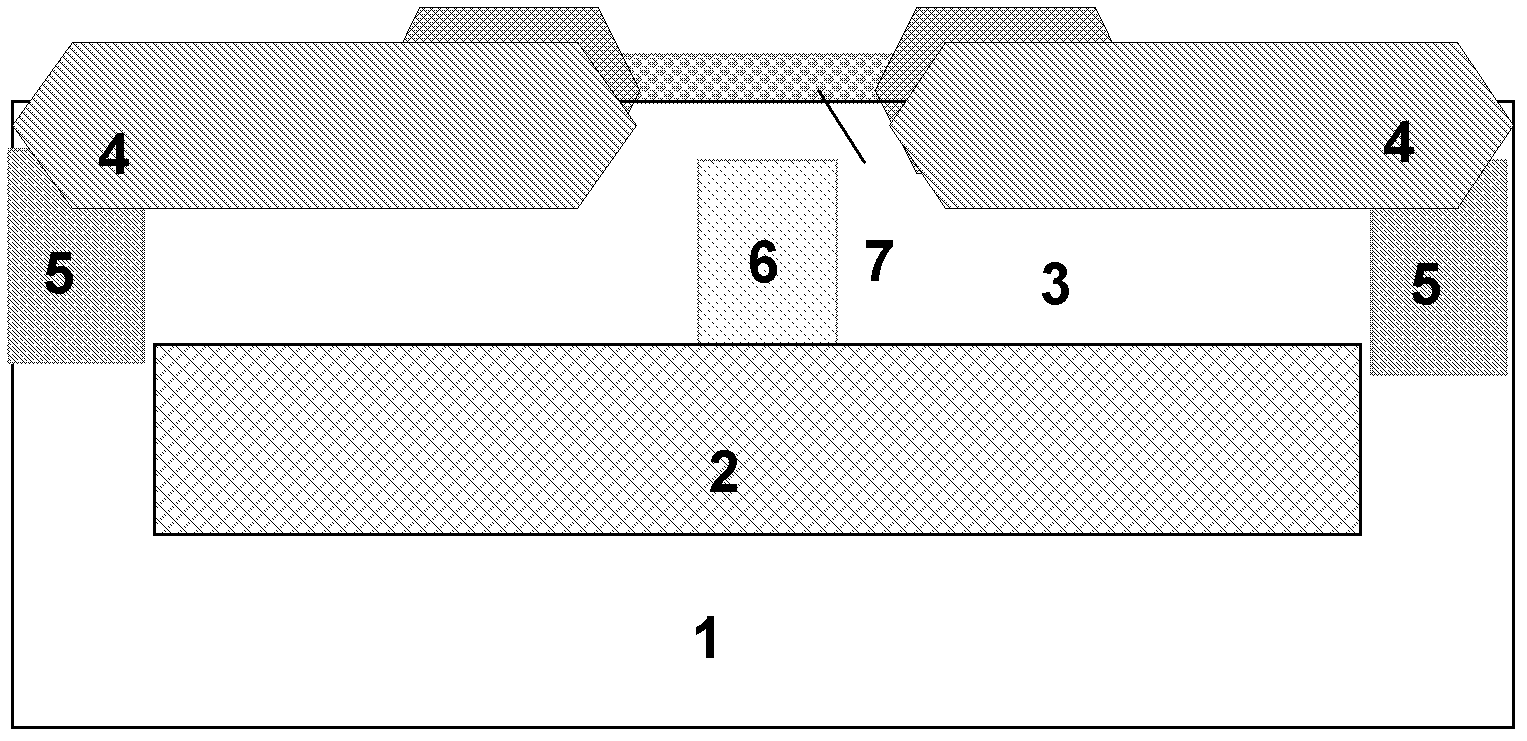

[0050] The manufacturing method of silicon germanium HBT single tube structure of the present invention comprises the following steps:

[0051] Step 1, carry out high dose (10 15 cm -2 ~10 16 cm -2 ), medium-energy (50KeV~100KeV) N-type ion implantation, high-temperature annealing after implantation, the temperature is between 1050°C and 1150°C, and the annealing time is more than 60 minutes to form a low-resistance N-type buried layer 2 channel, implant The ion is preferably arsenic, which is heavy enough to prevent further diffusion during the subsequent annealing process without causing significant damage to the silicon substrate;

[0052] Step 2, perform low N-doped epitaxial growth on the N-type buried layer, the thickness is between 0.8 μm and 2.0 μm, and the doping concentration is 10 15 cm -3 ~10 16 cm -3 ;

[0053] Step 3: Perform medium and high doses (10 14 cm -2 ~5×10 15 cm -2 ), medium-energy (50keV~200keV) P-type ion implantation to form a P-type ion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com