Ultra-low density block-shaped fully stabilized zirconia gel and preparing method thereof

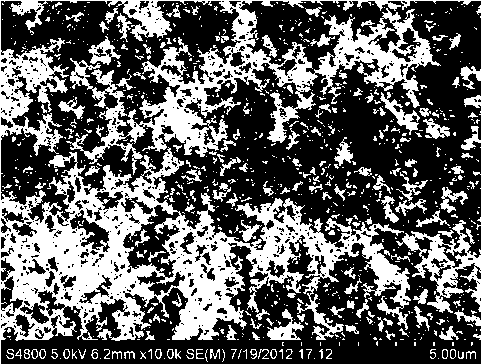

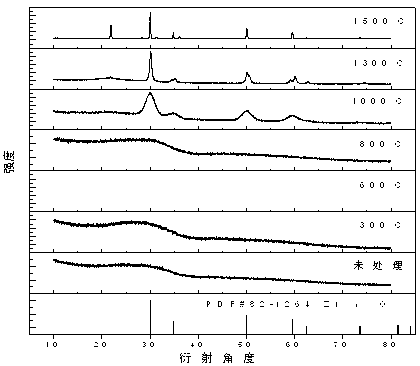

A fully stable zirconia, ultra-low density technology, applied in the field of material science, can solve the problems of high porosity, unsatisfactory effect, and inability to produce low density, etc., to achieve high porosity, excellent thermal stability, and microstructure units controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The preparation method of the zirconia airgel stabilized by ultra-low density bulk yttria comprises the following steps:

[0026] (1) Zirconium oxynitrate is used as the source of zirconium, and yttrium nitrate, calcium nitrate or magnesium nitrate is used as the stabilizer, wherein Y is expressed in molar percentage 2 o 3 : ZrO 2 =15-23%, CaO: ZrO 2 =10-20%, MgO:ZrO 2 =20-30%, add deionized water, seal with plastic wrap, put it on a magnetic stirrer and stir until completely dissolved, then add ethanol, continue to stir and mix evenly, the volume ratio of ethanol and deionized water is 4:1;

[0027](2) Add formamide and stir for 30 minutes; in terms of molar ratio, zirconyl nitrate: formamide = 1:1; add 1,2-propylene oxide, and stir while adding; in terms of molar ratio, zirconyl nitrate : 1,2-propylene oxide=1:3.8-1:12;

[0028] (3) Pour it into a petri dish, seal it with plastic wrap, put it in a tray, and put it in an oven at 60°C for gelation and aging proc...

Embodiment 1

[0033] (1) Add 0.92g of zirconium oxynitrate and 0.34g of yttrium nitrate hexahydrate, add 10ml of deionized water, seal it with plastic wrap, put it on a magnetic stirrer and stir until completely dissolved, then add 40ml of ethanol, continue to stir and mix evenly;

[0034] (2) Add 0.16ml formamide and stir for 30 minutes; add 3.41ml 1,2-propylene oxide and stir while adding;

[0035] (3) Pour it into a petri dish, seal it with plastic wrap, put it in a tray, and put it in an oven at 60°C for gelation and aging process to obtain a wet gel;

[0036] (4) Put the wet gel into a closed container filled with absolute ethanol, and put it in an oven at 60°C for aging for 3 days;

[0037] (5) Submerge the wet gel aged in absolute ethanol in a mixed solution of absolute ethanol and tetraethylorthosilicate with a volume ratio of 1:1, put it in an oven at 60°C for aging for 3 days, and finally use Dehydrated alcohol was aged for another 3 days to obtain the aged wet gel;

[0038] (7)...

Embodiment 2

[0040] (1) Add 2.3g of zirconyl nitrate and 0.73g of yttrium nitrate hexahydrate, add 10ml of deionized water, seal it with plastic wrap, put it on a magnetic stirrer and stir until completely dissolved, then add 40ml of ethanol, and continue to stir and mix evenly;

[0041] (2) Add 0.4ml formamide and stir for 30 minutes; add 3.41ml 1,2-propylene oxide and stir while adding;

[0042] (3) Pour it into a petri dish, seal it with plastic wrap, put it in a tray, and put it in an oven at 60°C for gelation and aging process to obtain a wet gel;

[0043] (4) Put the wet gel into a closed container filled with absolute ethanol, and put it in an oven at 60°C for aging for 3 days;

[0044] (5) Submerge the wet gel aged in absolute ethanol in a mixed solution of absolute ethanol and tetraethylorthosilicate with a volume ratio of 1:1, put it in an oven at 60°C for aging for 3 days, and finally use Dehydrated alcohol was aged for another 3 days to obtain the aged wet gel;

[0045] (7) F...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com