Preparation method of jarosite

A technology of jarosite and potassium permanganate, which is applied in the field of sulfate mineral preparation, can solve the problems of unfriendly environment, high preparation cost, and many reagents, and achieve the effects of simple process, mild reaction conditions, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0020] The preparation method of the jarosite of the present embodiment is as follows:

[0021] Dissolve 2.0 g of ammonium ferrous sulfate hexahydrate in 15 mL of distilled water, add 0.2 g of potassium permanganate while stirring, then transfer the mixed solution into a hydrothermal reaction kettle, and heat the reaction system temperature under airtight conditions to 140°C, and carried out hydrothermal reaction at this temperature for 16h.

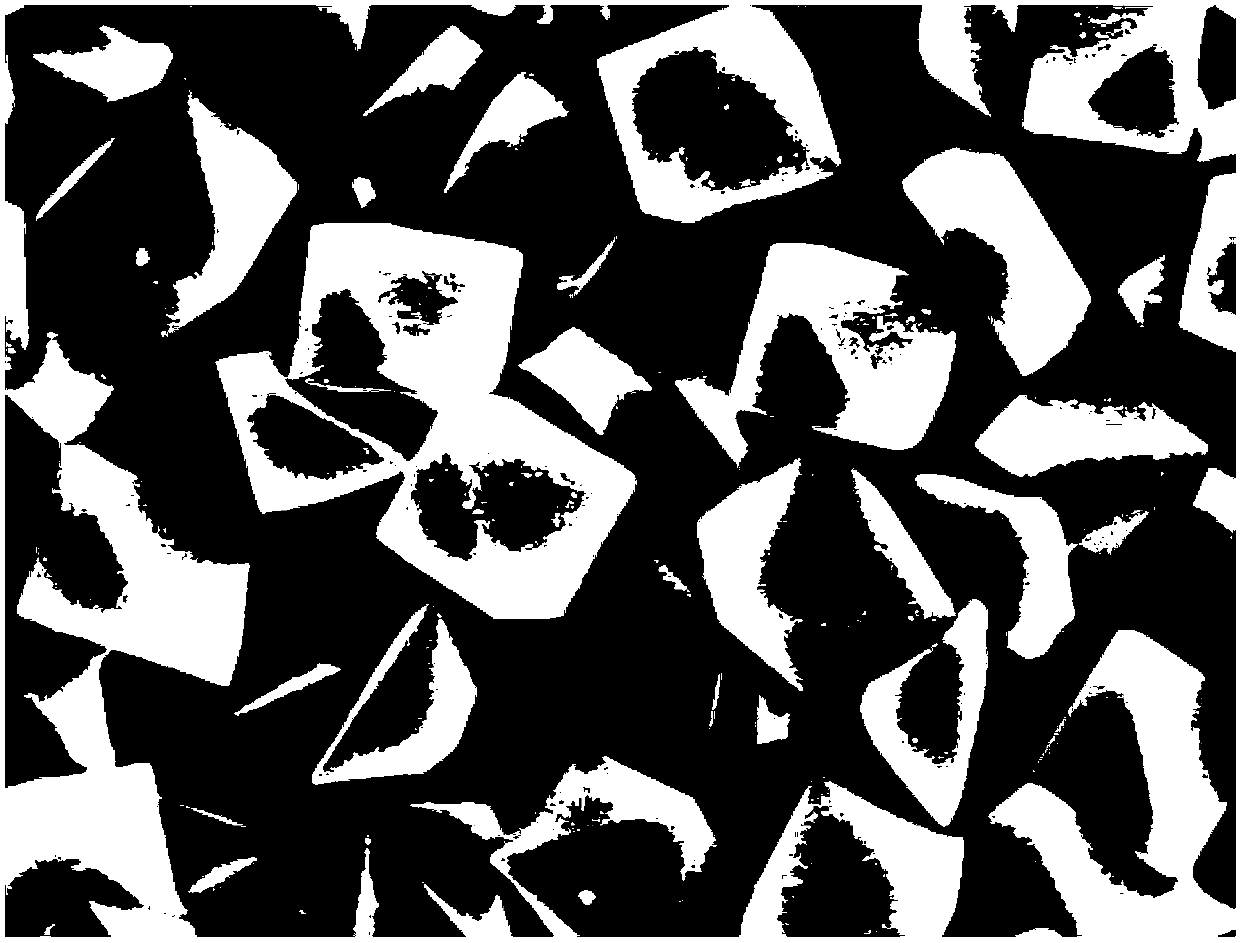

[0022] After the reaction is over, cool the reacted material naturally, filter, then wash the solid with distilled water and absolute ethanol in turn, and finally vacuum-dry it at a temperature of 80°C for 2 hours, and the air pressure in the drying oven is 0.02MPa to obtain a solid with a regular shape. And basically octahedral structure of jarosite powder, see figure 1 .

Embodiment 2~ Embodiment 6)

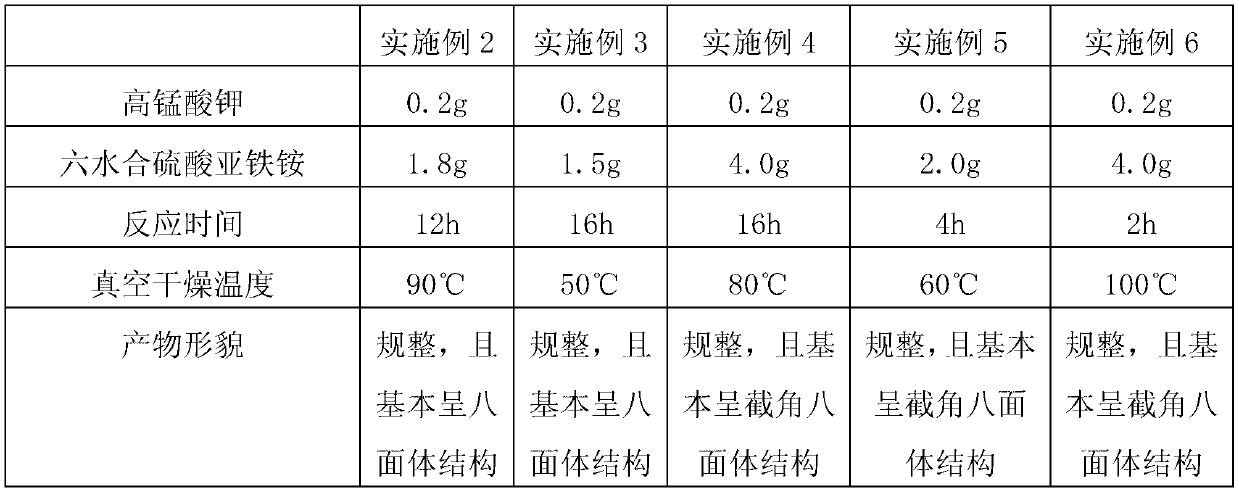

[0024] Each embodiment is basically the same as Embodiment 1, and the differences are shown in Table 1.

[0025] Table 1

[0026]

[0027] .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com