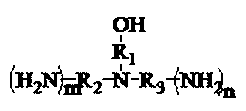

Polyether amine and preparation method thereof

A polyetheramine and polymer technology, applied in the field of polymer material synthesis and preparation, can solve the problems of strict process requirements, high yield and high cost, and achieve the effects of reducing side reactions, reducing costs and avoiding strict requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) In a three-necked flask, dissolve triethylenetetramine and acetone in toluene at a molar ratio of 1:2.5, control the reaction temperature at 90-130°C, react for 6-10 hours, separate the liquid and produce water, and the conversion rate is 95%; Remove toluene, water and excess acetone in the system to obtain triethylenetetramine protected by ketimine;

[0028] (2) Add triethylenetetramine (2mol) and sodium ethoxide (0.3wt%) protected by ketimine into the polymerization reactor, pass through argon protection, add propylene oxide (50mol) dropwise to react, and control the pressure to 0.1~10MPa, after the feeding is completed, continue to react for 5h to obtain polyetheramine protected by ketimine; then add phosphoric acid (0.4mol), deionized water (30mol) and adsorbent (5wt%), at 60~150℃ Hydrolyze for 1 hour to remove the ketimine protecting group, then remove the acetone in the system at a temperature range of 50-130°C, and finally filter to obtain the polyetheramine ...

Embodiment 2

[0030] (1) In a three-necked flask, dissolve tetraethylenepentamine and butyraldehyde in toluene at a molar ratio of 1:3, control the reaction temperature at 90-130°C, react for 5-9 hours, separate the liquid and effluent, and the conversion rate is 93% ; Remove toluene, water and excessive butyraldehyde in the system to obtain the tetraethylenepentamine of aldimine protection;

[0031] (2) Add aldimine-protected tetraethylenepentamine (1mol) and potassium oxide (0.3wt%) into the polymerization reactor, pass through argon protection, add dropwise ethylene oxide (20mol), and control the pressure to 0.1 ~10MPa, after the addition, continue to react for 5h to obtain aldimine-protected polyetheramine; then add oxalic acid (0.5mol), deionized water (35mol) and adsorbent (5wt%), hydrolyze at 60~150℃ Remove the aldimine protecting group for 1 hour, then remove butyraldehyde in the system at a temperature range of 50-130°C, and filter to obtain the polyetheramine product.

Embodiment 3

[0033] (1) In a three-necked flask, dissolve N-aminoethylpiperazine and acetone in toluene at a molar ratio of 1:4, control the reaction temperature at 60-100°C, react for 5-8 hours, and separate the liquid to produce water; remove the system Toluene in, water and excess acetone, obtain the aminoethylpiperazine of ketimine protection;

[0034] (2) Add ketimine-protected aminoethylpiperazine (1mol) and sodium methoxide (0.5wt%) into the polymerization reactor, pass through argon protection, add dropwise butylene oxide (40mol), and control the pressure to 0.1~10MPa, after the feeding is completed, continue to react for 5h to obtain polyetheramine protected by ketimine; then add oxalic acid (0.5mol), deionized water (40mol) and adsorbent (8wt%), at 60~150℃ Hydrolyze for 1 hour to remove the ketimine protecting group, then remove the acetone in the system at a temperature range of 50-130°C, and filter to obtain the polyetheramine product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com