Gene engineering strain Streptomyces chattanoogensis L11 construction and culture method

A technology of genetically engineered strains and Streptomyces caata, applied in the field of microorganisms, can solve the problems of low fermentation unit and long fermentation period, and achieve the effect of increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Acquisition of L11

[0026] (1) Solid culture: inoculate the strain of Streptomyces chattanooga L11 (CGMCC No. 7182) in solid medium, culture in an incubator at 28°C for 10 days, and collect spores;

[0027] (2) Liquid culture: After solid culture, inoculate the spores into the seed medium, culture on a shaker at 30°C for 24 hours at 200 rpm, inoculate into the fermentation culture, inoculum amount 5% (V / V), and cultivate for 168 hours to obtain .

[0028] The solid medium in step (1) is: 0.4% of yeast extract, 1% of malt extract, 0.4% of glucose, 0.2% of calcium carbonate, 2% of agarose, the rest is water, and the pH is adjusted to 7.2. The percentages are all percentages by mass.

[0029] The seed culture medium in step (2) is: 1.75% glucose, 1.5% peptone, 1.0% NaCl, and the rest is water, and the percentages mentioned above are all mass percentages.

[0030] The fermentation medium in step (2) is: 2.8% of raw soybean cake powder, 0.7% of yeast powder, ...

Embodiment 2

[0033] Example 2 Fermentation Verification of L11

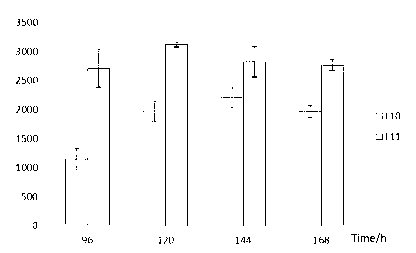

[0034] Inoculate 20 μl of L11 spores into the seed medium at 200 rpm and incubate at 30°C for 24 hours; inoculate the mycelium in the seed medium into the fermentation medium to OD 600 0.15, rotation speed 200 rpm, 30°C for 168 hours, after 12, 24, 48, 72, 96, 120, 144, and 168 hours of cultivation, samples were taken to determine the natamycin production.

[0035] The natamycin standard substance was made into a solution of a certain concentration with methanol, and the OD was measured by a UV-visible spectrophotometer 303 and OD 290 Absorbance to establish natamycin concentration - OD 303 and OD 290 The standard curve of the difference between the two; take 1 ml of the bacterial liquid fermented by the fermentation medium, add 9 ml of methanol, vortex vigorously for 5 minutes, centrifuge to get the supernatant, dilute to a certain multiple with methanol, and measure the OD 303 and OD290 The difference in absorbance wa...

Embodiment 3

[0036] Example 3 Traits and genetic stability of L11

[0037] L11 was cultured on slant medium for 10 days, the hyphae in the base and the aerial hyphae developed well, the spore filaments were flexible or curved, the spores were oval, and the surface was spiny ( figure 2 ). The results of the appearance characteristics in various media are shown in Table 1; the physiological and biochemical characteristics of L11 are shown in Table 2. The spores of strain L11 were collected after being cultured on slant medium for 10 days, and the spores were stored in 10% glycerol at -80°C for 0-6 months, and the genetic traits and natamycin fermentation units were stable.

[0038]

[0039]

[0040] Zhejiang University

[0041] Construction and cultivation method of genetic engineering strain Streptomyces chattanooga L11

[0042] 3

[0043]

[0044] 1

[0045] 660

[0046] DNA

[0047]

[0048] Streptomyces chattanoogensis L11

[0049] 1

[0050] atgatcgaca aactgc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com