Method for analytical separation sodium ibandronate and impurities thereof by utilizing high performance liquid chromatography (HPLC)

A technology for analysis and separation of ibandronate sodium, applied in the field of analysis of ibandronate sodium raw materials and preparations, can solve the problems of increased detection cost, many interference factors, low accuracy, etc., and achieve reduced detection cost, accurate High accuracy, high accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] Instruments and Conditions

[0084] High performance liquid chromatography: Shimadzu: LC-20ATSPD-M20A

[0085] Chromatographic column: C18 (150×4.6mm)

[0086] Mobile phase: 0.02mol / L potassium dihydrogen phosphate (0.01% EDTA): acetonitrile=97:3

[0087] Flow rate: 1.2mL / min

[0088] Detection wavelength: 200nm

[0089] Injection volume: 20μL

[0090] Experimental steps:

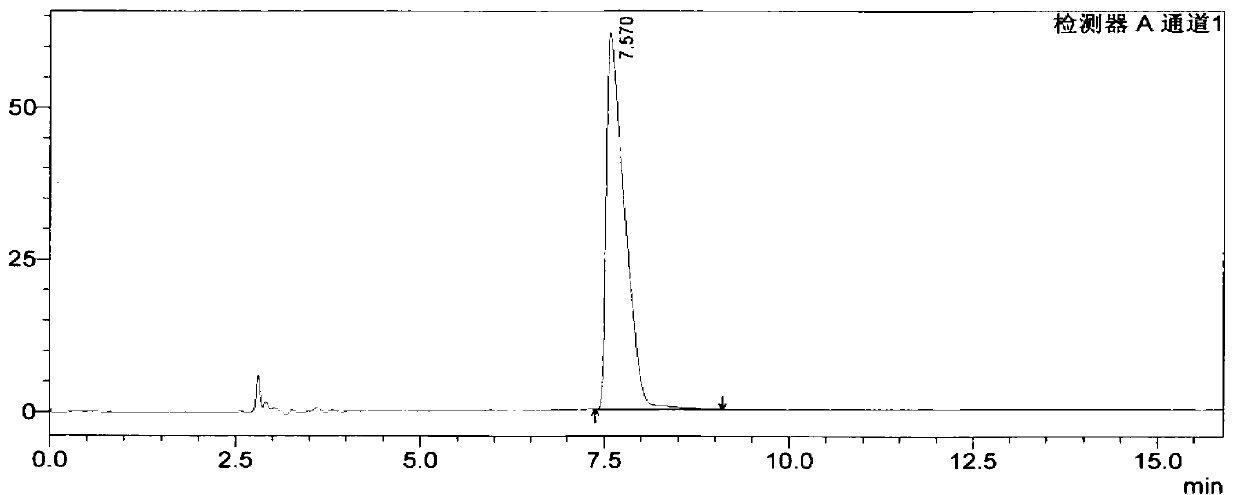

[0091] Take ibandronate sodium impurity I: 10.2mg, impurity II: 9.9mg and ibandronate sodium: 10.3mg, put them in three 10mL measuring bottles respectively, add mobile phase to dissolve and dilute to the mark, as the reference substance solution, Then accurately weigh ibandronate sodium raw material: 10.5mg, impurity I: 10.0mg, impurity II: 10.7mg and place in the same 10ml measuring bottle, add mobile phase to dissolve and dilute to the mark, as the test solution. Get above-mentioned solution and carry out high performance liquid chromatography analysis according to above-mentioned chromatogra...

Embodiment 2

[0094] Instruments and Conditions

[0095] High performance liquid chromatography: Agilent1200

[0096] Chromatographic column: C8 (200×4.6mm)

[0097] Mobile phase: 0.01mol / L sodium dihydrogen phosphate (0.01%EDTA):methanol=98:2

[0098] Flow rate: 0.8mL / min

[0099] Detection wavelength: 195nm

[0100] Injection volume: 10μL

[0101] Experimental procedure

[0102] The preparation method of need testing solution is with embodiment 1.

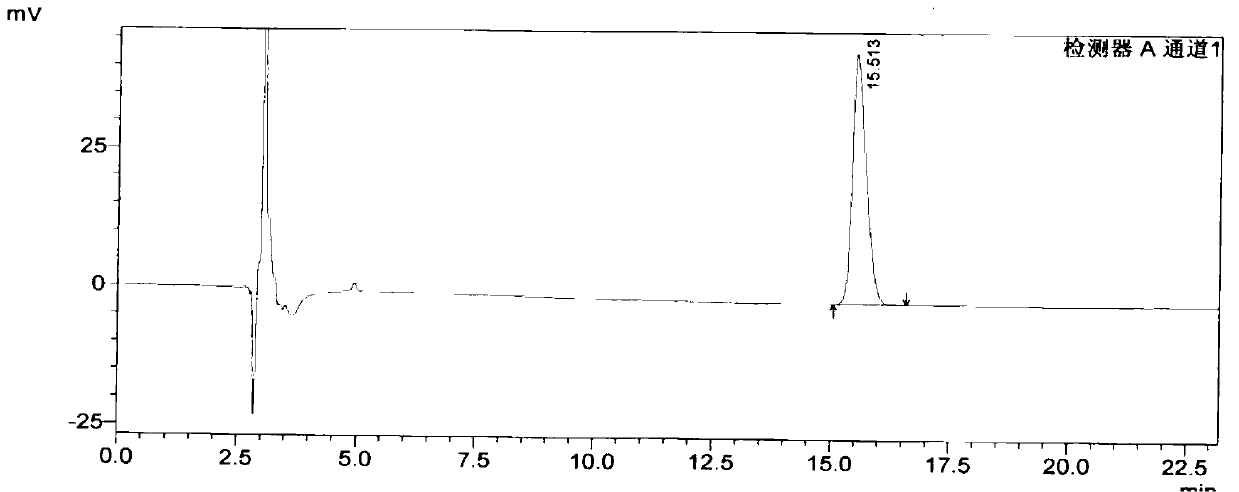

[0103] Get need testing solution, carry out HPLC analysis by above-mentioned chromatographic condition, record chromatogram, the result sees attached Figure 5 . In the figure, peak No. 1 is the chromatographic peak of impurity II, peak No. 2 is the chromatographic peak of ibandronic acid, and peak No. 3 is the chromatographic peak of impurity I. It can be seen that under this condition, ibandronic acid and two of them All impurities can be effectively separated, and the retention time of ibandronic acid is about 12.3min.

Embodiment 3

[0105] Instruments and Conditions

[0106] High performance liquid chromatography: Agilent1200

[0107] Chromatographic column: C18 (250×4.6mm)

[0108] Mobile phase: 0.05mol / L potassium dihydrogen phosphate (0.01% EDTA):methanol=94:6

[0109] Flow rate: 1.0mL / min

[0110] Detection wavelength: 205nm

[0111] Injection volume: 50μL

[0112] Experimental procedure

[0113] The preparation method of need testing solution is with embodiment 1.

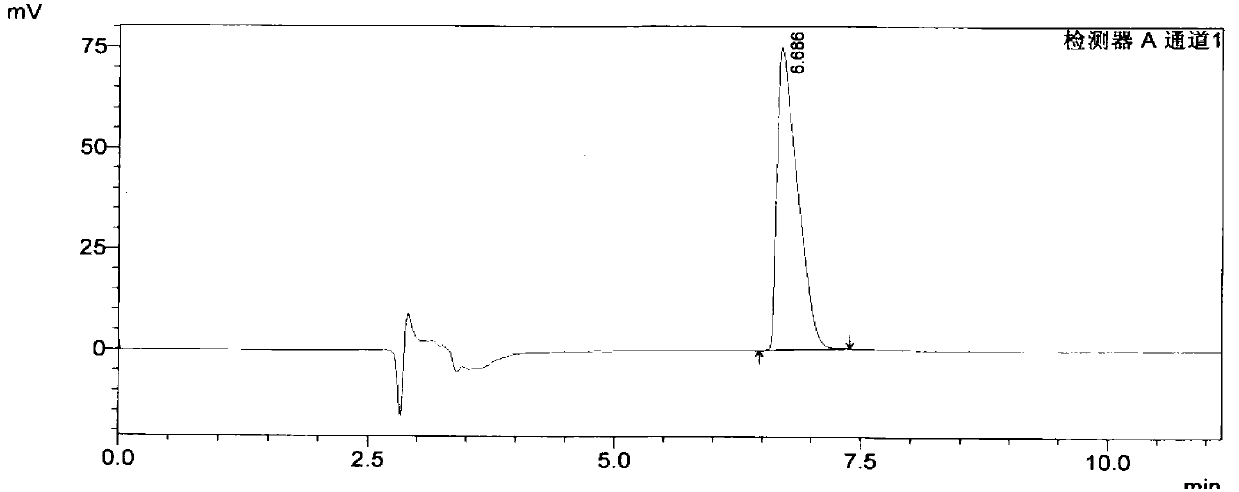

[0114] Get need testing solution, carry out HPLC analysis by above-mentioned chromatographic condition, record chromatogram, the result sees attached Image 6 .

[0115] In the figure, peak No. 1 is the chromatographic peak of impurity II, peak No. 2 is the chromatographic peak of ibandronic acid, and peak No. 3 is the chromatographic peak of impurity I. It can be seen that under this condition, ibandronic acid and two of them All impurities can be separated effectively, and the retention time of ibandronic acid is about 8.3min. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com