Spina date seed total saponin dispersible tablet and preparation method thereof

The technology of total saponins from jujube seed and jujube seed saponins is applied in the field of dispersible tablets of total saponins from jujube seed and its preparation, which can solve the problems of affecting the full absorption of drugs, slow drug dissolution of tablets, trouble for patients and the like, so as to avoid excessive local concentration. , to avoid the effect of poor stability and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

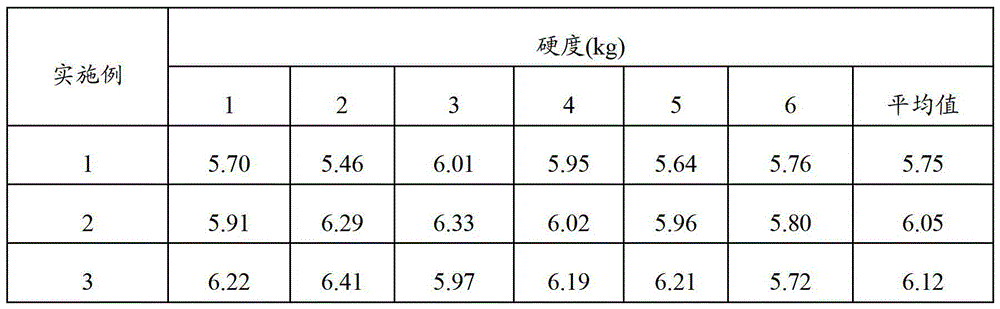

Examples

Embodiment 1

[0023] 1. Weigh jujube seed saponin extract 5.0g, croscarmellose sodium 3.0g, microcrystalline cellulose 10g, talcum powder 1.0g, stevioside 0.5g, and grind them through 80-mesh sieve respectively for later use.

[0024] 2. Jujube seed saponin extract is used as raw material drug, microcrystalline cellulose is used as filler, croscarmellose sodium is used as disintegrating agent, stevioside is used as flavoring agent, and 75% ethanol solution is used as The wetting agent is made into soft material, granulated with 18-mesh stainless steel sieve, the wet granules are dried in an oven at 50-60°C for 1-2 hours, and the dried granules are granulated through an 18-mesh sieve.

[0025] 3. Add talcum powder to the above-mentioned dry granules, mix evenly with the method of increasing in equal amounts, and press into tablets to make 50 dispersible tablets of total saponins of Jujube Semen.

Embodiment 2

[0027] 1. Take jujube seed saponin extract 5.0g, croscarmellose sodium 3.5g, compressible starch 5g, microcrystalline cellulose 5g, magnesium stearate 0.5g, stevioside 0.5g, and grind them respectively Finely sieve and set aside.

[0028] 2. Jujube seed saponin extract is used as the raw material drug, compressible starch and microcrystalline cellulose are used as fillers (the mass ratio of compressible starch and microcrystalline cellulose is 1:1), and cross-linked carboxymethyl Cellulose sodium is used as a disintegrating agent, stevioside is used as a flavoring agent, and 75% ethanol solution is used as a wetting agent to make a soft material, granulated with a 18-mesh stainless steel sieve, and the wet granules are dried in an oven at 50-60°C for 1 -2 hours, the dried granules are passed through a 18-mesh sieve for granulation.

[0029] 3. Add magnesium stearate to the above-mentioned dry granules, mix evenly with the method of equal increase, and tablet to make 50 Zizior...

Embodiment 3

[0031] 1. Weigh 5.0g of jujube seed saponin extract, 3.0g of croscarmellose sodium, 5g of compressible starch, 5g of microcrystalline cellulose, 1.0g of talcum powder, and 0.5g of stevioside, and grind them finely Sieve and set aside.

[0032] 2. Jujube seed saponin extract is used as the raw material drug, compressible starch and microcrystalline cellulose are used as fillers (the mass ratio of compressible starch and microcrystalline cellulose is 1:1), and cross-linked carboxymethyl Cellulose sodium is used as a disintegrating agent, stevioside is used as a flavoring agent, and 75% ethanol solution is used as a wetting agent to make a soft material, granulated with a 18-mesh stainless steel sieve, and the wet granules are dried in an oven at 50-60°C for 1 -2 hours, the dried granules are passed through a 18-mesh sieve for granulation.

[0033] 3. Add talcum powder to the above-mentioned dry granules, mix evenly with the method of increasing in equal amounts, and press into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com