Method for extracting anthocyanidin from aria

A technology of anthocyanin and extraction solution, applied in the direction of organic chemistry, which can solve the problems of high process conditions, long extraction time, high equipment cost, etc., and achieve the effect of simple and easy operation, short extraction time and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

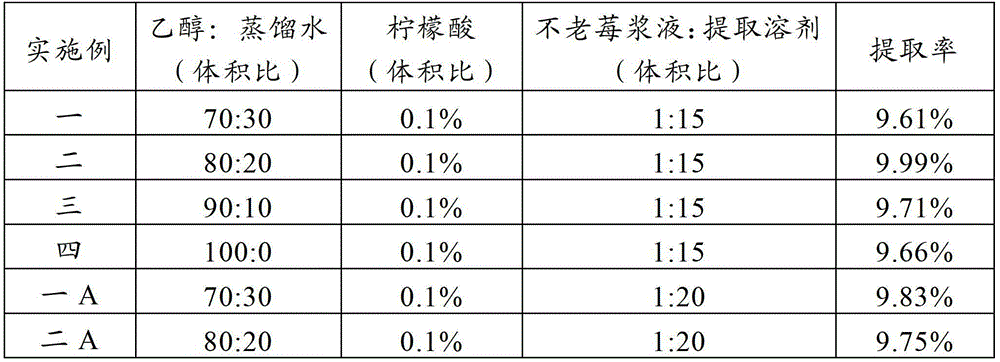

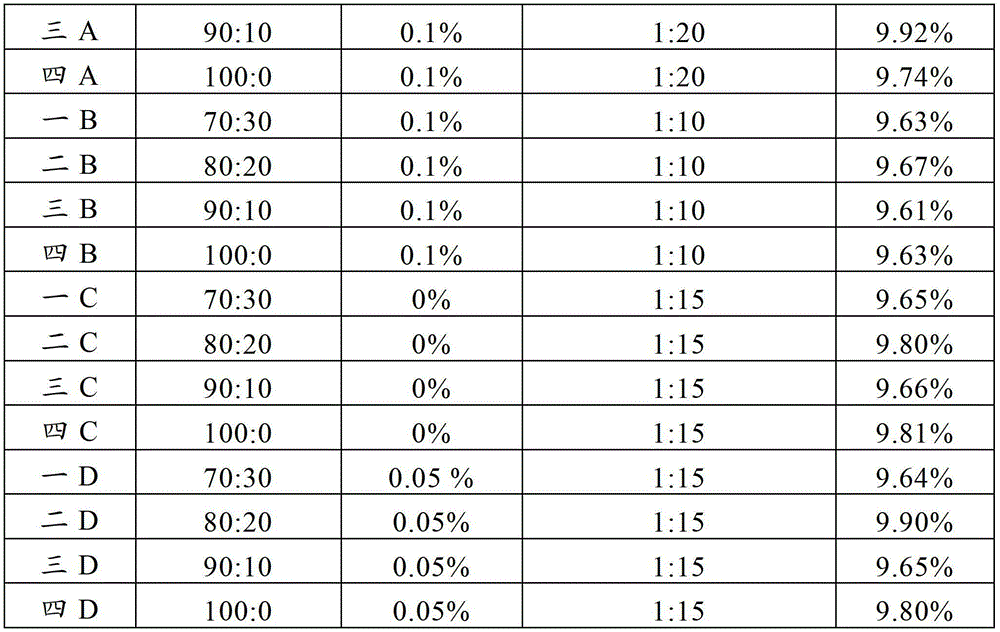

Embodiment 1

[0034] (1) 500g of oldberry is pulverized and beaten by a beater to obtain the oldberry slurry;

[0035] (2) Ethanol: distilled water (volume ratio) = 70:30, 0.1% citric acid and mix well as the extraction solvent; take 20g of bulangberry slurry and 300ml of extraction solvent, mix well, and use a full-temperature shaker at 30℃~33℃ for 250r / min vibration extraction 60min;

[0036] (3) After shaking and extracting, filter the mixture of slurry and extraction solvent, centrifuge at 4200r / min for 15min, and collect the supernatant as the extract;

[0037] (4) The extract is concentrated by vacuum rotary evaporation in a water bath at 40°C, and most of the ethanol is removed to obtain an anthocyanin concentrate;

[0038] (5) Measure the content of monomeric anthocyanins, and obtain 1.83g of monomeric anthocyanins per 100g of berry, and the extraction rate is 9.61%.

Embodiment 2

[0040] (1) 500g of oldberry is pulverized and beaten by a beater to obtain the oldberry slurry;

[0041] (2) Ethanol: distilled water (volume ratio) = 80:20, 0.1% citric acid and mix well as the extraction solvent; take 20g of berry slurry and 300ml of extraction solvent, mix well, and use a full-temperature shaker at 30℃~33℃ for 250r / min vibration extraction 60min;

[0042] (3) After shaking and extracting, filter the mixture of slurry and extraction solvent, centrifuge at 4200r / min for 15min, and collect the supernatant as the extract;

[0043] (4) The extract is concentrated by vacuum rotary evaporation under the condition of 42°C water bath, most of the ethanol is removed, and anthocyanin concentrate is obtained;

[0044] (5) Measure the content of monomeric anthocyanins, and obtain 1.90g of monomeric anthocyanins per 100g of berry, and the extraction rate is 9.99%.

Embodiment 3

[0046] (1) 500g of oldberry is pulverized and beaten by a beater to obtain the oldberry slurry;

[0047] (2) Ethanol: distilled water (volume ratio) = 90:10, and 0.1% citric acid are mixed evenly as the extraction solvent; take 20g of the berry slurry and 300ml of the extraction solvent, mix evenly, and shake with a full-temperature oscillator at 30°C to 33°C 250r / min extraction 60min;

[0048] (3) After shaking and extracting, filter the mixture of slurry and extraction solvent, centrifuge at 4200r / min for 15min, and collect the supernatant as the extract;

[0049] (4) The extract is concentrated by vacuum rotary evaporation under the condition of 42°C water bath, most of the ethanol is removed, and anthocyanin concentrate is obtained;

[0050] (5) Measure the content of monomeric anthocyanins, and obtain 1.85g of monomeric anthocyanins per 100g of berry, and the extraction rate is 9.71%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com