Phosphazene fire retardant graft modification carbon nano tube and preparation method thereof

A phosphazene flame retardant, carbon nanotube technology, applied in the direction of fibrous filler, dyed low-molecular-weight organic compounds, etc., can solve the problems of high cost, complicated reaction process, etc., achieve high conversion rate, large preparation amount, improve dispersive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

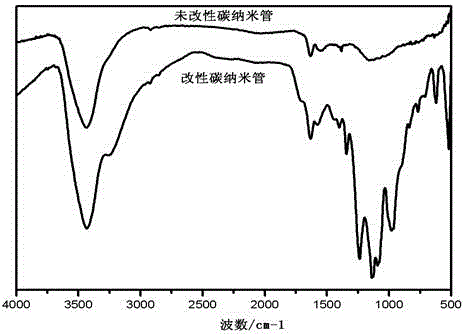

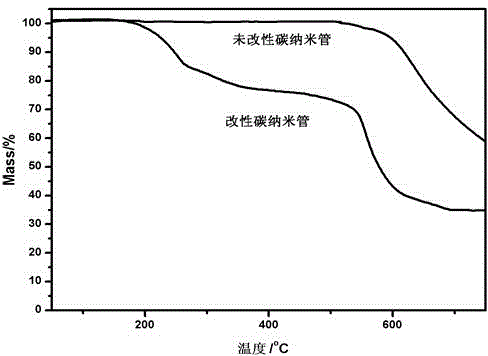

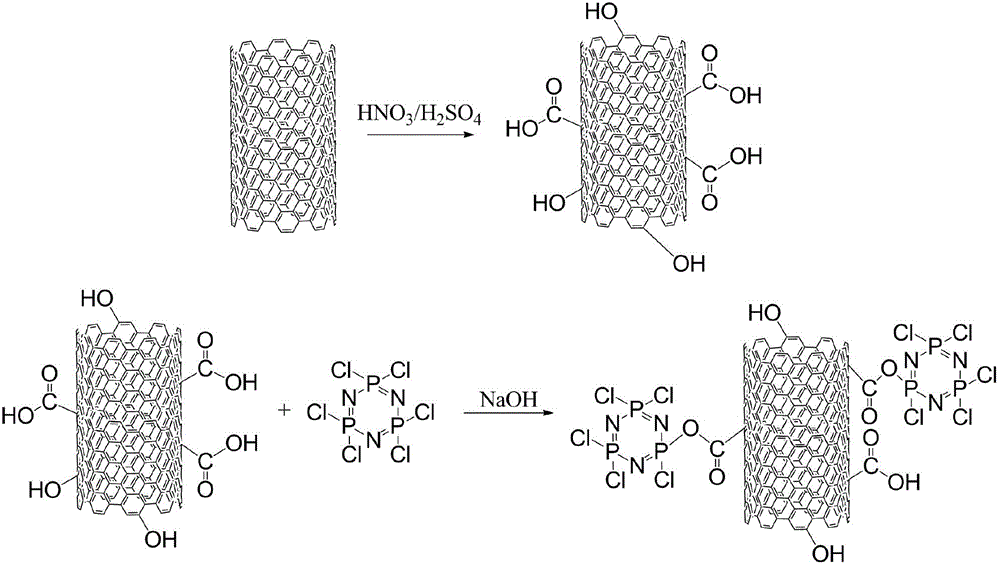

[0025] (1) Add 2 g of purified carbon nanotubes into a conical flask filled with 45 ml of concentrated sulfuric acid and concentrated nitric acid (volume ratio 3:1), and ultrasonicate at 50°C for 3 hours. After sonication, pour a large amount of deionized water to dilute, vacuum filter and continuously wash with deionized water until neutral. The solid was dried in a vacuum oven at 80° C. for 12 h to constant weight to obtain acidified carbon nanotubes.

[0026] (2) Take 2g of acidified carbon nanotubes, 2g of hexachlorocyclotriphosphazene, 0.7g of sodium hydroxide, and 80ml of tetrahydrofuran, pour them into a three-necked flask and mix them thoroughly, and ultrasonicate for 30 minutes to fully dissolve and disperse them. After purging nitrogen for 20 minutes to remove oxygen, the reaction was refluxed for 36 hours at 65° C. under strong magnetic stirring. After the reaction, the obtained product was vacuum filtered, washed with tetrahydrofuran and acetone several times, and...

Embodiment 2

[0030] (1) Add 2 g of purified carbon nanotubes into a conical flask filled with 45 ml of concentrated sulfuric acid and concentrated nitric acid (volume ratio 3:1), and sonicate at 50°C for 4 hours. After sonication, pour a large amount of deionized water to dilute, vacuum filter and continuously wash with deionized water until neutral. The solid was dried in a vacuum oven at 80° C. for 12 h to constant weight to obtain acidified carbon nanotubes.

[0031] (2) Take 2g of acidified carbon nanotubes, 2g of hexachlorocyclotriphosphazene, 0.7g of sodium hydroxide, and 80ml of tetrahydrofuran, pour them into a three-necked flask and mix them thoroughly, and ultrasonicate for 30 minutes to fully dissolve and disperse them. After purging nitrogen for 20 minutes to remove oxygen, the reaction was refluxed for 36 hours at 65° C. under strong magnetic stirring. After the reaction, the obtained product was vacuum filtered, washed with tetrahydrofuran and acetone several times, and drie...

Embodiment 3

[0033] (1) Add 2 g of purified carbon nanotubes into a conical flask filled with 45 ml of concentrated sulfuric acid and concentrated nitric acid (volume ratio 3:1), and ultrasonicate at 50°C for 5 hours. After sonication, pour a large amount of deionized water to dilute, vacuum filter and continuously wash with deionized water until neutral. The solid was dried in a vacuum oven at 80° C. for 12 h to constant weight to obtain acidified carbon nanotubes.

[0034] (2) Take 2g of acidified carbon nanotubes, 2g of hexachlorocyclotriphosphazene, 0.7g of sodium hydroxide, and 80ml of tetrahydrofuran, pour them into a three-necked flask and mix them thoroughly, and ultrasonicate for 30 minutes to fully dissolve and disperse them. After purging nitrogen for 20 minutes to remove oxygen, the reaction was refluxed for 48 hours at 65° C. under strong magnetic stirring. After the reaction, the obtained product was vacuum filtered, washed with tetrahydrofuran and acetone several times, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com