Quick thermal cracking technique and device of biomass with fused salt

A thermal cracking and biomass technology, applied in molten salt/molten metal gasification, chemical industry, sustainable manufacturing/processing, etc. Use performance, effect of continuous feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

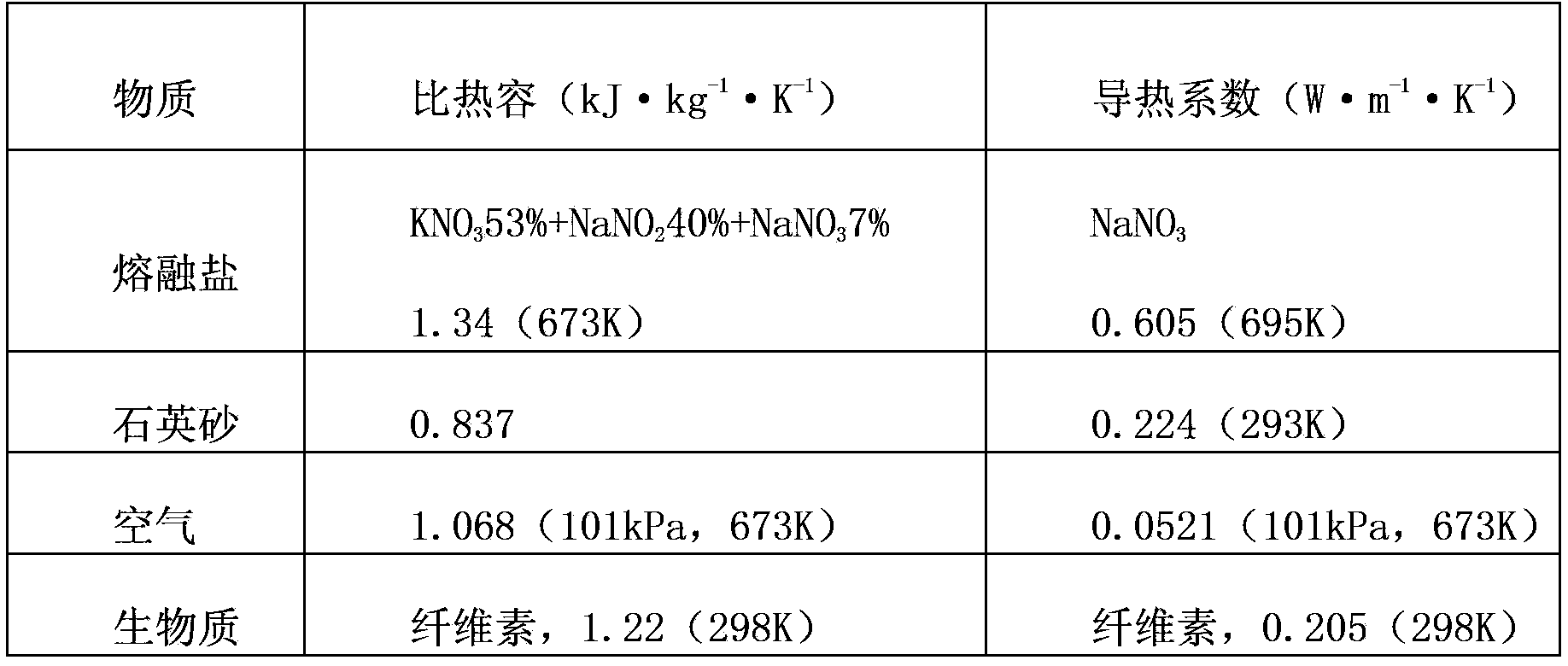

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

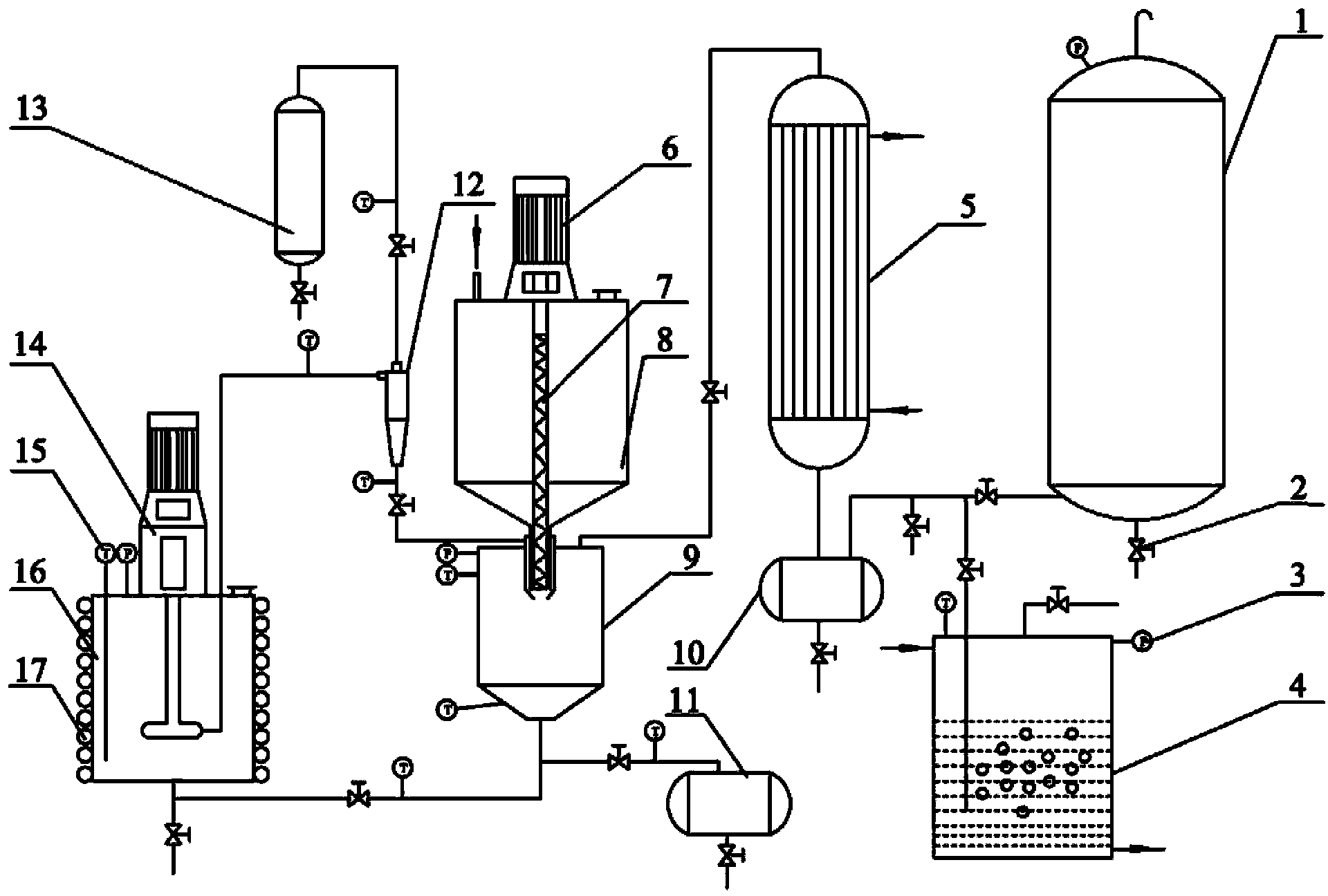

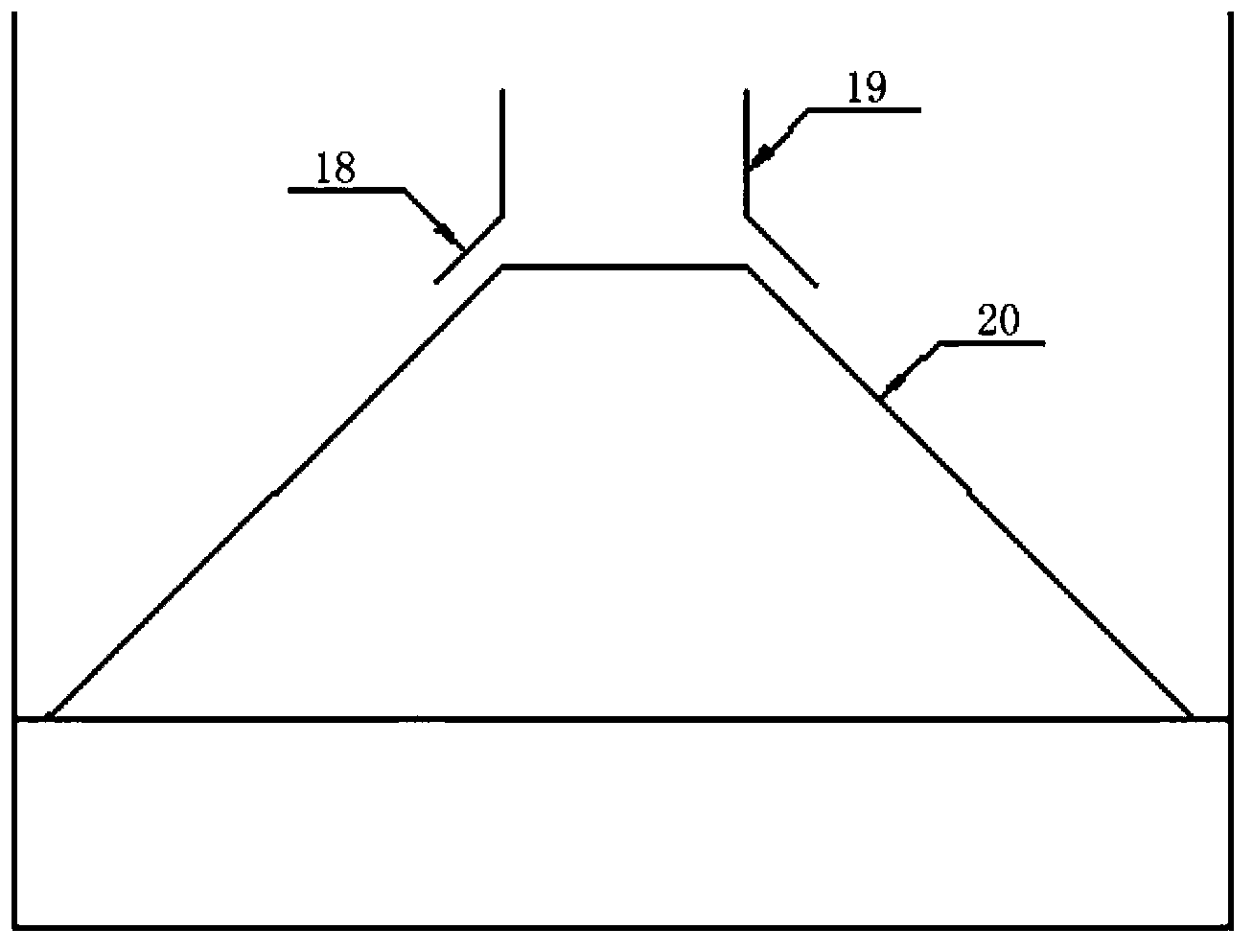

[0043] refer to figure 1 and figure 2 A process and device for co-producing bio-oil and biochar using crop stalks, the composition of molten salt is selected as ZnCl 2 / KCl (molar ratio is 7 / 6) molten salt system, the mass is 160kg; the biomass raw material used is rice straw, the mass is 4kg, and the particle size is 100 mesh; the thermal cracking temperature is 450°C; the pipeline control temperature is 450°C; vacuumize. The pyrolysis results obtained are as follows:

[0044] (1) Liquid phase yield The yield rate is 25wt.%. The elemental analysis of the liquid phase product is carried out with an elemental analyzer. The elemental composition is: C element 2.47%, H element 7.904%, N element 0.99%, S element 0.012% , O element 88.624%.

[0045] (2) The liquid phase product is GC7890A / MS5975C of Agilent Company (Santa Clara, CA), and the chromatographic column is Agilent 19091S-433; 325° C.; 30 m×250 μm×0.25 μm. The analysis conditions are: GC carrier gas is He; flow rate...

Embodiment 2

[0049] Select the molten salt composition as ZnCl 2 / KCl (molar ratio is 7 / 6) molten salt system, the mass is 166kg; the biomass raw material used is rice straw, the mass is 5kg, and the particle size is 100 mesh; the pyrolysis temperature is 450°C; the pipeline control temperature is 450°C; vacuumize. The pyrolysis results obtained are as follows:

[0050] (1) Liquid phase yield The yield is 30wt.%. The elemental analysis of the liquid phase product is carried out with an elemental analyzer. The elemental composition is: C element 1.92%, H element 4.46%, N element 0.73%, S element 0.045% , O element 92.85%.

[0051] (2) The GC / MS analysis results of the liquid phase products were: phenols 56.70%, aldehydes 30.29%, alcohols 1.20%, esters 9.39%, acids 2.40%.

[0052] (3) The gas phase product composition distribution in the cracking process is: H 2 1.81%~28.16%, CO4.12%~14.67%, CH 4 3.38%~8.70%, CO 2 62.99% to 87.14%.

[0053] (4) The element composition of the solid pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| cracking temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com