Dedicated bacterial strains for producing indigo blue pigments

An indigo pigment and production technology, applied in microorganism-based methods, bacteria, microorganisms, etc., can solve the problems of long strain culture period, low pigment secretion capacity, unstable enzyme, etc., and achieve constant synthesis capacity, simple operation, and production. Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

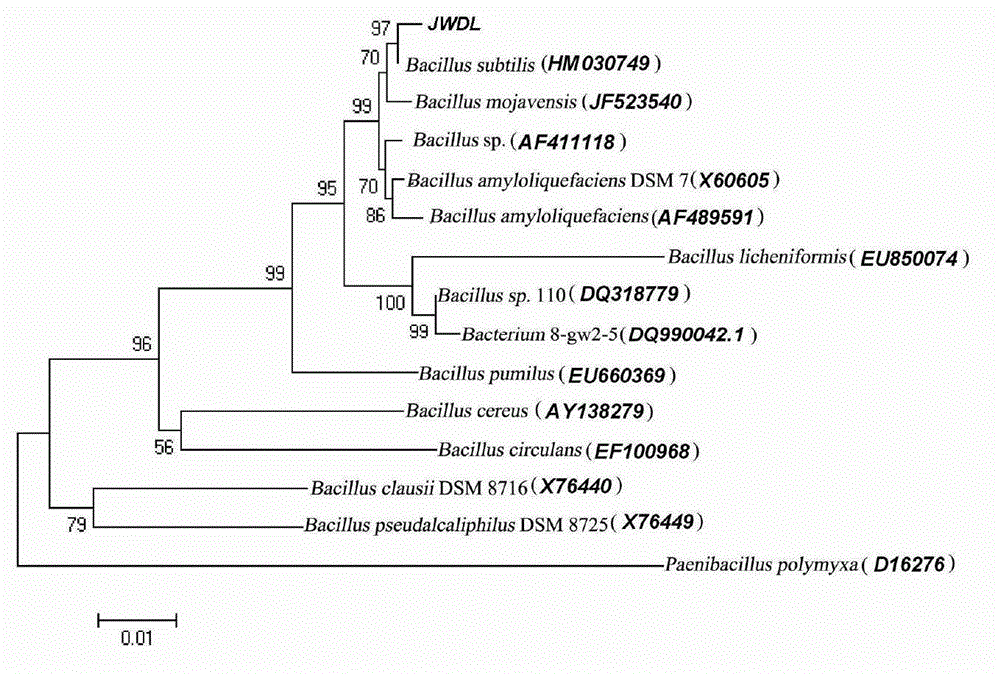

[0029] The screening identification of embodiment 1 producing indigo pigment strain

[0030] 1. Sample collection

[0031] Soil samples were collected from the sludge near the sewage treatment plant in Xuzhou City, Jiangsu Province.

[0032] 2. Isolation and screening of bacterial strains On September 12, 2011, soil samples were collected from the sludge of Kuihe River, Xuzhou City, Jiangsu Province, and the soil samples were collected from Dagao Zhaojian.

[0033] Prepare solid primary screening medium (unit g / 100ml): yeast extract 0.2, NaCl 0.2, (NH 4 ) 2 SO 4 0.2, NH 4 NO 3 0.1,K 2 HPO 4 0.01, MgSO 4 ·7H 2 O 0.01, FeSO 4 ·7H 2 O0.004, agar powder 1.5, pH7.5. The prepared culture is based on 121°C, sterilized for 15 minutes, and poured onto the plate. Indole was made into an indole solution with a final concentration of 0.5g / 100ml with ethanol, and the sterilized medium was cooled to about 50°C, and 3ml of indole solution was added per 100ml of medium, mixed w...

Embodiment 2

[0039] The fermentation culture of embodiment 2 bacterial strains and the extraction of indigo pigment crude product

[0040] 1. Culture of strains

[0041] Prepare seed liquid medium (unit g / 100ml): peptone 1, glucose 0.5, yeast powder 0.5, NaCl 0.2, (NH 4 ) 2 SO 4 0.2, NH 4 NO 3 0.1,K 2 HPO 4 0.01, MgSO 4 ·7H 2 O 0.01, pH7.5. The prepared culture is based on 121°C and sterilized for 15 minutes. Inoculate a single colony of the strain JWDL into the above medium, fill a 250ml Erlenmeyer bottle with 40ml of liquid, and culture with shaking at 32°C and 180r / min for 20h.

[0042] Preparation of fermentation medium (g / L): peptone 0.5, glucose 0.5, yeast powder 0.5, (NH 4 ) 2 5O 4 0.25, MgSO 4 ·7H 2 O0.01, FeSO 4 ·7H 2 O0.04, NH 4 NO 3 0.1, pH7.5. The prepared culture is based on 121°C and sterilized for 15 minutes. Inoculate the cultured seed liquid into the sterilized fermentation medium according to the inoculum amount of 4%, fill the volume of liquid in ...

Embodiment 3

[0045] The structural identification of embodiment 3 pigment

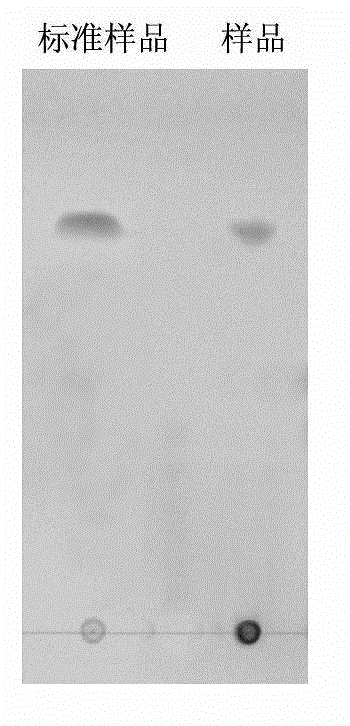

[0046] 1. Thin-layer chromatography (TLC) analysis: the prepared crude indigo sample was dissolved in N,N-dimethylformamide (DMF). The sample and the standard sample were respectively spotted on the thin electrode of TLC. The developing solvent is methanol-acetone / 1:1 (v / v) solvent system. After fully unfolding, blow dry with a hair dryer. The result is as figure 2 As shown, a blue spot appears at the same position on the chromatographic plate.

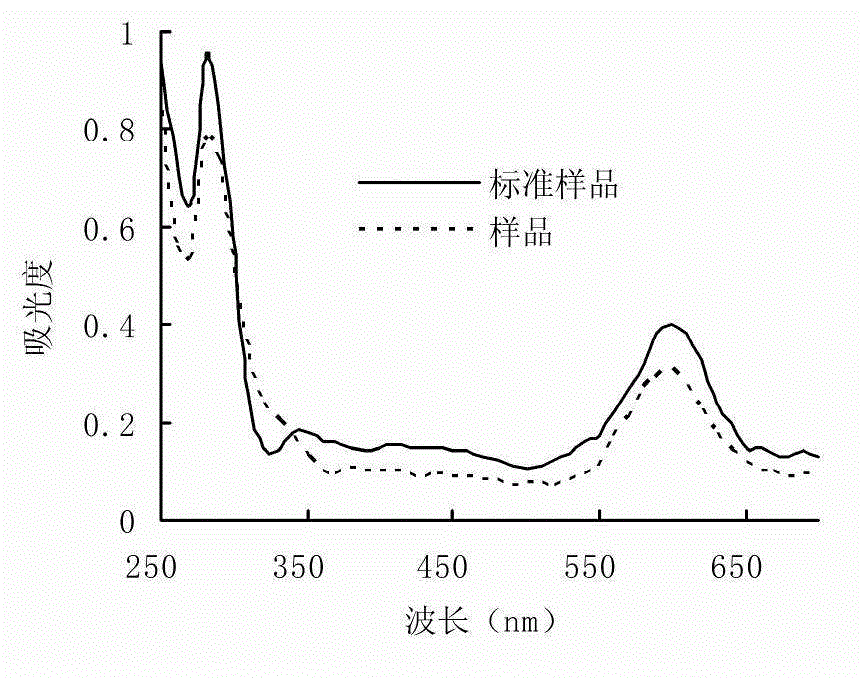

[0047] 2. Ultraviolet-visible broad-spectrum scanning analysis: the indigo sample dissolved in N,N-dimethylformamide (DMF) is the same as the standard indigo sample, and the ultraviolet-visible (250nm-700nm) broad-spectrum scanning is performed. The result is as image 3 As shown, the prepared sample is basically consistent with the scanning broad-spectrum absorption curve of the standard sample, and both show absorption peaks at 285nm and 600nm. This proves that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com