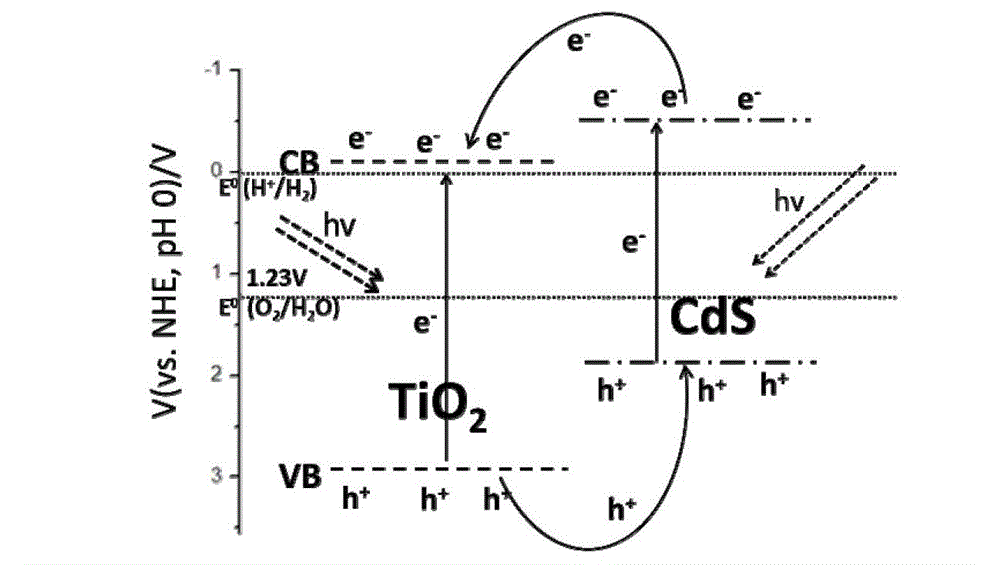

Cadmium sulfide (CdS) quantum dot sensitized branching titanium dioxide (TiO2) nanorod array electrode and preparation method and usage thereof

A nanorod array and quantum dot sensitization technology, applied in the field of photoelectrochemistry, can solve the problems of insufficient stability of CdS, unusable nanorod array materials, small contact area, etc., so as to alleviate the shortage of fossil fuels, improve the efficiency of photolysis, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

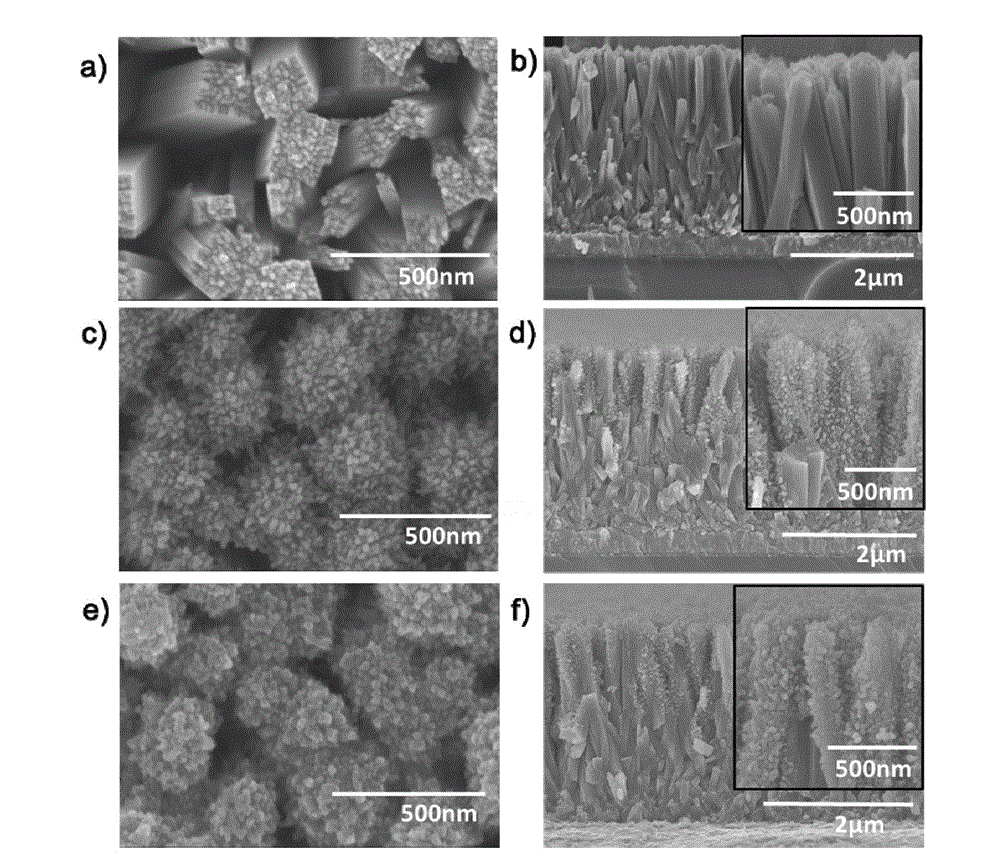

[0045] (1) TiO 2 Fabrication of Nanorod Arrays

[0046] ① Sonicate the FTO conductive glass in deionized water, acetone and ethanol solution for 10 minutes successively, wash it with deionized water, and dry it for later use;

[0047] ② Prepare the precursor solution of titanium source: first mix 30ml of concentrated hydrochloric acid (37.5% mass concentration) with 30ml of deionized water, stir for 5 minutes, add 1ml of butyl titanate and continue stirring for 5 minutes to obtain the titanium source precursor solution ;

[0048] ③ Place the conductive surface of the FTO conductive glass obliquely downward in the crystallization kettle, add the titanium source precursor solution, and hydrothermally synthesize it at 150°C for 14 hours to prepare TiO 2 Nanorod arrays were washed with deionized water and dried at 80°C.

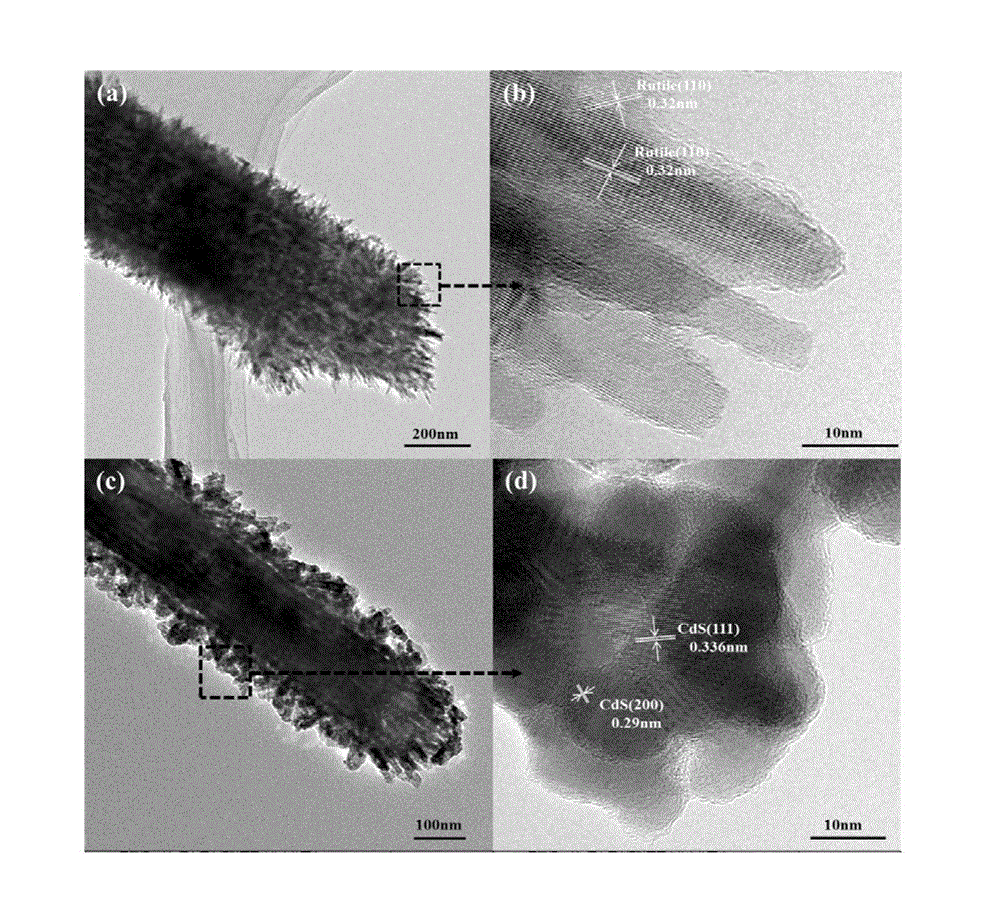

[0049] (2) Branched TiO 2 Fabrication of Nanorod Arrays

[0050] ① Prepare 0.2M TiCl 4 Aqueous solution: the preparation process is to take a certain amoun...

Embodiment 2

[0066] (1) TiO 2 The preparation of the nanorod array is the same as in Example 1.

[0067] (2) Branched TiO 2 The preparation of the nanorod array is the same as in Example 1.

[0068] (3) CdS quantum dots sensitized branched TiO 2 Fabrication of Nanorod Arrays

[0069] ① Prepare 0.1M Cd(NO 3 ) 2 Aqueous solution, 0.1M Na 2 S aqueous solution;

[0070] ② branched TiO 2 CdS quantum dots sensitized branched TiO prepared by continuous chemical water bath deposition with nanorod arrays as substrates through multiple sensitization cycles 2 Nanorod Arrays:

[0071] A single sensitization cycle is to first convert the branched TiO 2 Nanorod arrays soaked in Cd(NO 3 ) 2 in aqueous solution, rinsed after 5 minutes, and then put in Na 2 S aqueous solution, rinse after 5 minutes;

[0072] Repeat the sensitization cycle operation 7 times to obtain CdS quantum dot sensitized branched TiO 2 Nanorod array electrodes.

[0073] The experimental results show that the diameter o...

Embodiment 3

[0076] (1) TiO 2 The preparation of the nanorod array is the same as in Example 1.

[0077] (2) Branched TiO 2 Fabrication of Nanorod Arrays

[0078] ① Prepare 0.1M TiCl 4 Aqueous solution: the preparation process is to take a certain amount of TiCl under stirring conditions 4 soluble in ice water;

[0079] ②The prepared TiO 2 Nanorod arrays placed in 0.2M TiCl 4 In aqueous solution, amorphous branched TiO was prepared by chemical water bath deposition under sealed conditions for 24 hours 2 nanorod arrays;

[0080] ③Under the condition of 450℃, the above-prepared amorphous branched TiO 2 The nanorod arrays were fired for 30 min under air atmosphere to form branched TiO 2 nanorod arrays.

[0081] (3) CdS quantum dots sensitized branched TiO 2 Fabrication of Nanorod Arrays

[0082] ① Prepare 0.01M CdCl 2 Aqueous solution, 0.01M Na 2 S aqueous solution;

[0083] ② branched TiO 2 CdS quantum dots sensitized branched TiO prepared by continuous chemical water bath de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com