Purification enrichment pre-treatment technology for food packaging material and container transfer pollutant bisphenol substance

A technology for food packaging and bisphenols, which is applied in the field of purification and enrichment of bisphenols using solid phase extraction, can solve problems such as food pollution and achieve high recovery rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

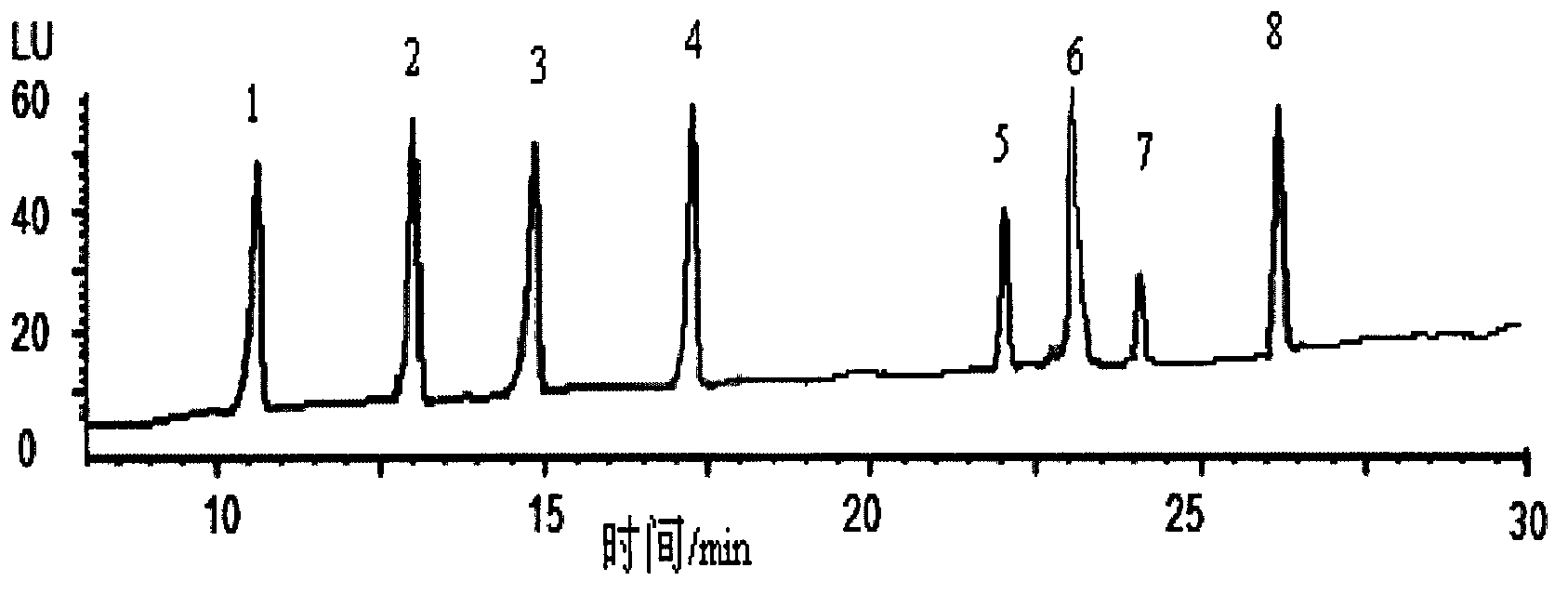

[0016] Simultaneous detection of 6 bisphenols (BPA, BPB, BPE, BPF, BADGE and BFDGE) by HPLC-FD, the selected chromatographic column is Symmetry C 18 (4.6×250mm, 5μm); column temperature: 25°C; injection volume: 20μL; mobile phase: ultrapure water and acetonitrile; gradient elution program see Table 1; flow rate: 1.0mL / min; excitation wavelength of fluorescence detector 227nm, absorption wavelength 313nm.

[0017] The HPLC-FD spectra of 6 kinds of bisphenols are attached figure 1 , the regression equation of the quantitative standard curve is shown in Table 2.

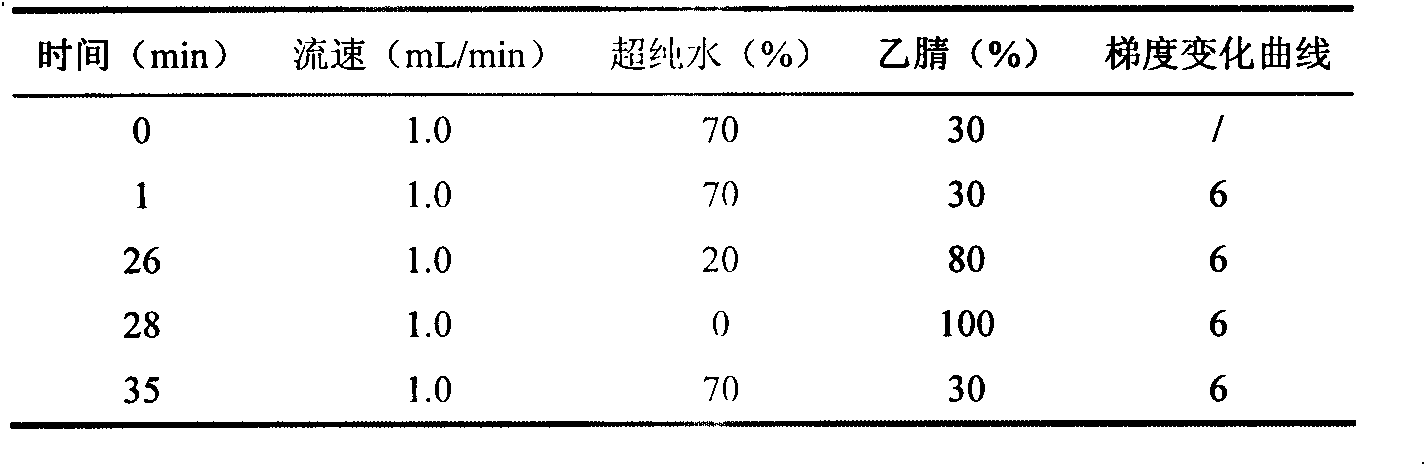

[0018] Table 1 Gradient elution conditions

[0019]

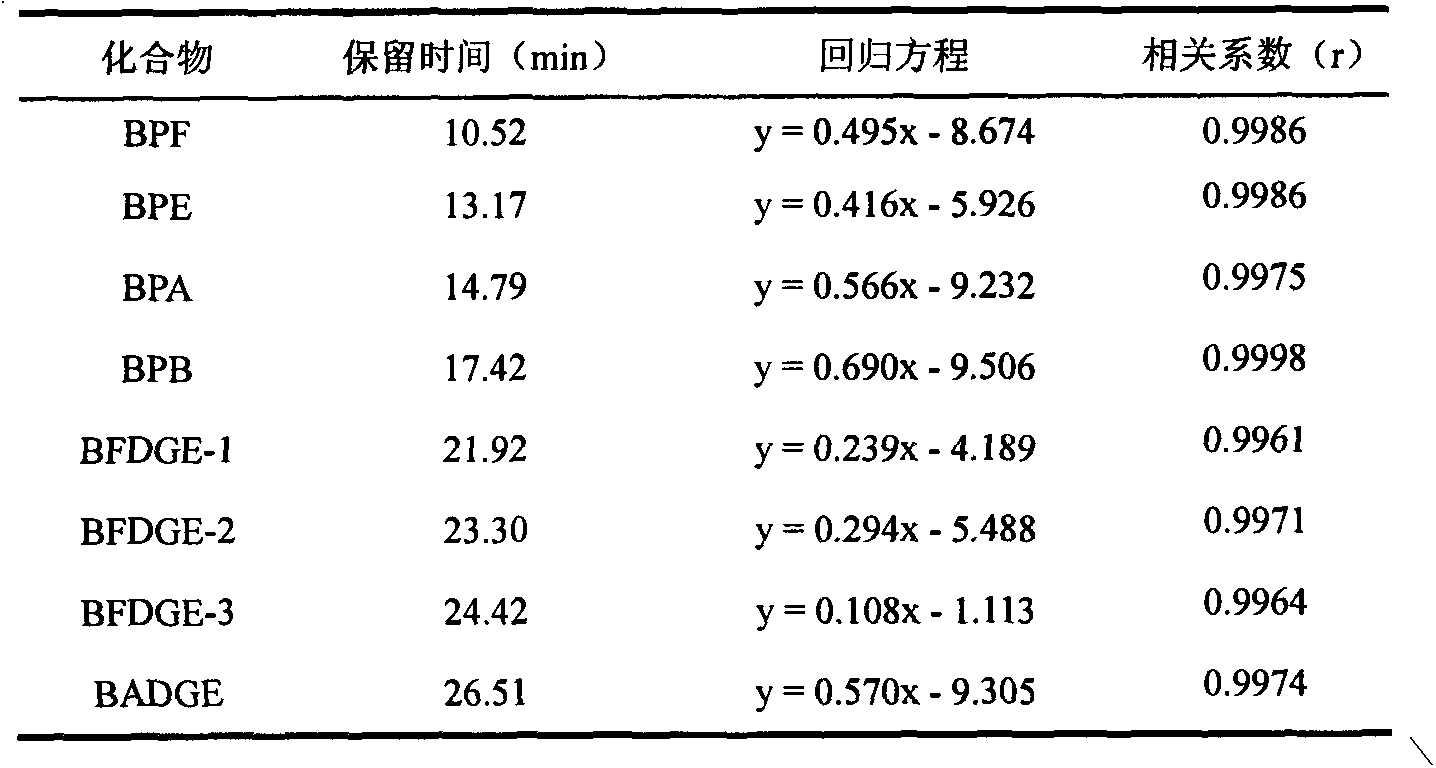

[0020] Table 2HPLC-FD detects the linear parameters of 6 kinds of bisphenol compounds

[0021]

Embodiment 2

[0023] Six kinds of bisphenols (BPA, BPB, BPE, BPF, BADGE and BFDGE) were mixed and diluted with ultrapure water so that the concentration of each substance was 100 μg / L. Will CNWBOND LC 18 SPE small column (500mg / 3mL) was activated with 5mL methanol and 5mL water, put 100mL standard solution in a 125mL separatory funnel, slowly introduce it into the SPE device, and control the flow rate to about 2mL / min. After all the solution passed through the small column, rinse the separatory funnel with 10 mL of ultrapure water. Next, rinse the SPE cartridge with 3 mL of 20% methanol solution. Finally, 6 mL of methanol was added dropwise twice to elute the target substance, and the eluate was collected into a 10 mL test tube, blown dry slowly with nitrogen at 40°C, then reconstituted the residue with 1 mL of acetonitrile, and filtered the acetonitrile with a 0.45 μm PTFE needle filter solution, and carry out HPLC-FD detection, and assay condition is as embodiment 1. To verify the reco...

Embodiment 3

[0028] Six bisphenols (BPA, BPB, BPE, BPF, BADGE and BFDGE) were mixed and diluted with 3% acetic acid solution to make the concentrations of each substance 20 μg / L, 50 μg / L, and 100 μg / L, respectively. Will CNWBOND LC 18 The SPE cartridge (500mg / 3mL) was activated with 5mL of methanol and 5mL of water, and 100mL of the above-mentioned 3% acetic acid solution with different concentrations was placed in a 125mL separatory funnel, and slowly introduced into the SPE device, and the flow rate was controlled at about 2mL / min. After all the solution passed through the small column, rinse the separatory funnel with 10 mL of ultrapure water. Next, rinse the SPE cartridge with 3 mL of 20% methanol solution. Finally, 6 mL of methanol was added dropwise twice to elute the target substance, and the eluate was collected into a 10 mL test tube, blown dry slowly with nitrogen at 40°C, then reconstituted the residue with 1 mL of acetonitrile, and filtered the acetonitrile with a 0.45 μm PTFE...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com