Rare-earth sulfide thermoelectric material and preparation method thereof

A rare earth sulfide and thermoelectric material technology, which is applied in the field of rare earth sulfide thermoelectric materials and their preparation, can solve the problems of difficult control of carrier concentration, high processing temperature, etc., achieves good industrial application prospects, improves thermoelectric performance, and improves thermoelectricity. The effect of merit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

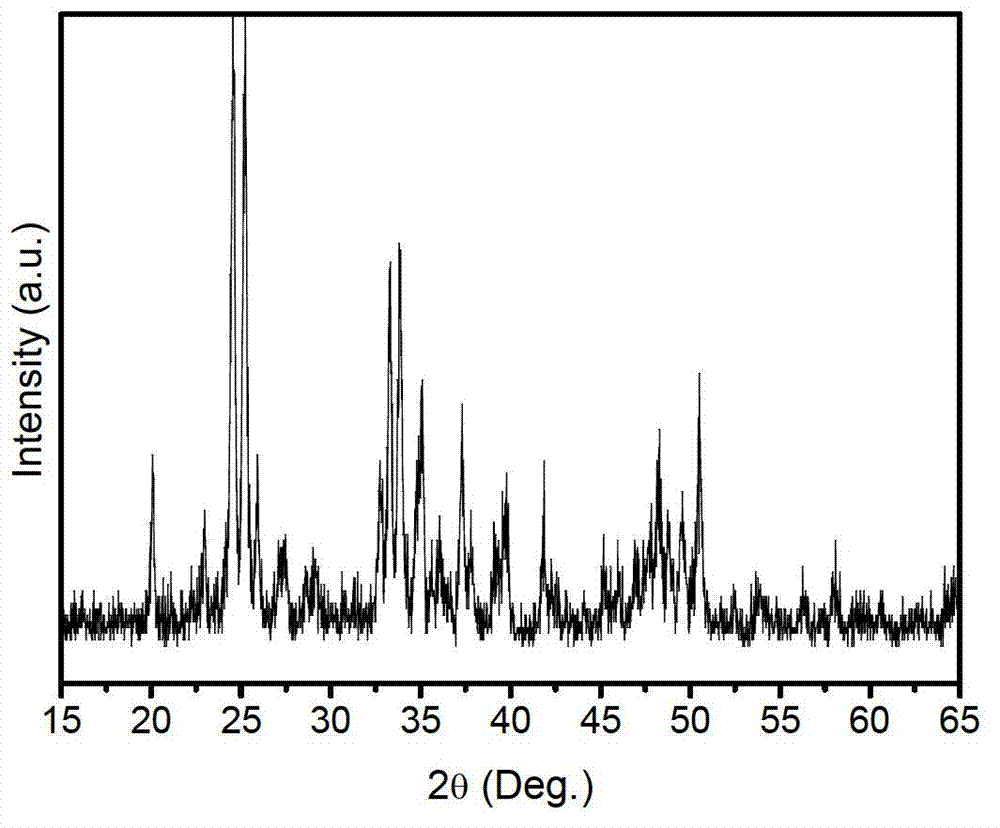

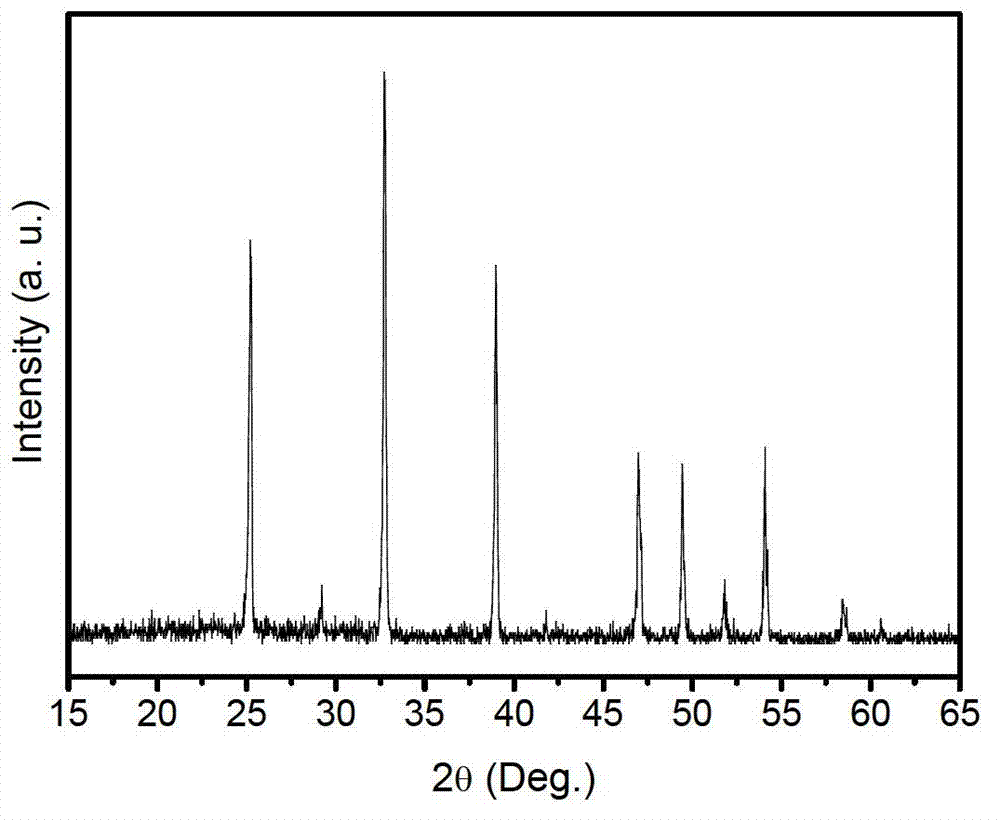

[0026] Raw materials (calcium oxide, lanthanum oxide, cerium oxide) according to the chemical composition formula Ca 0.02 La 0.8 Ce 1.18 S 3 The initial mixture is obtained after calculation and weighing. After the initial mixture is finely ground and mixed, it is vulcanized at 1000°C for 3 hours in a hydrogen sulfide atmosphere, and the powder material is obtained after cooling. The X-ray diffraction pattern of the powder sample is shown in figure 1 . The obtained powder material is pulverized and formed, and vacuum hot-pressed and sintered at 1400° C. under a pressure of 50 MPa for 10 minutes. After cooling, a pure cubic bulk thermoelectric material is obtained. The X-ray diffraction pattern of the sintered sample is shown in figure 2 .

Embodiment 2

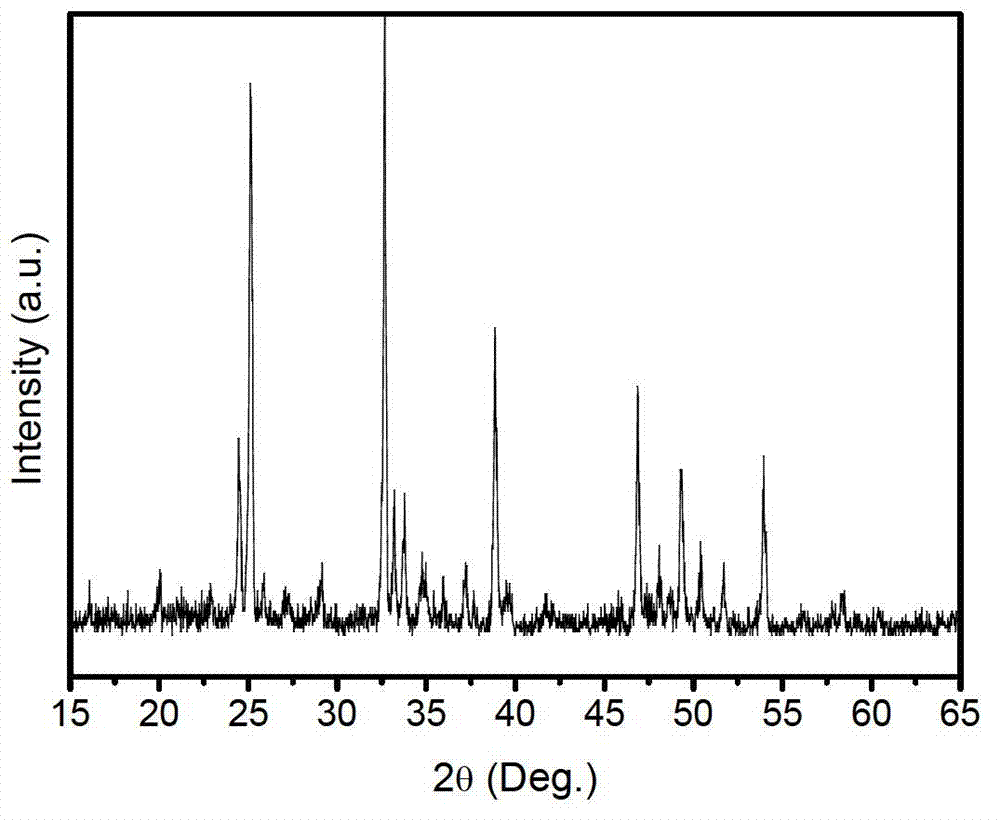

[0028] Raw materials (calcium carbonate, lanthanum carbonate, cerium carbonate) according to the chemical composition formula Ca 0.03 La 0.5 Ce 1.47 S 3 The initial mixture is obtained after calculation and weighing. After the initial mixture is finely ground and mixed, it is vulcanized in a carbon disulfide atmosphere at 1200°C for 2 hours, and the powder material is obtained after cooling. The X-ray diffraction pattern of the powder sample is shown in image 3 . The obtained powder material is pulverized and formed, and vacuum discharge plasma sintering is carried out at 1500° C. under a pressure of 30 MPa for 20 minutes. After cooling, a block thermoelectric material of pure cubic crystal system is obtained.

Embodiment 3

[0030] Raw materials (calcium nitrate, lanthanum nitrate, cerium nitrate) according to the chemical composition formula Ca 0.04 La 0.4 Ce 1.56 S 3 The initial mixture is obtained after calculation and weighing. After the initial mixture is finely ground and mixed, it is vulcanized in a hydrogen sulfide atmosphere at 1300°C for 2 hours, and the powder material is obtained after cooling. The X-ray diffraction pattern of the powder sample is shown in Figure 4 . The obtained powder material is pulverized and formed, and vacuum hot-pressed and sintered at 1600° C. under a pressure of 80 MPa for 30 minutes. After cooling, a pure cubic bulk thermoelectric material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com