Method for refining and purifying propylene oxide

A technology of propylene oxide and propane, which is applied in the field of refining propylene oxide, can solve the problems of long process and high energy consumption, and achieve the effects of increasing yield, reducing losses, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

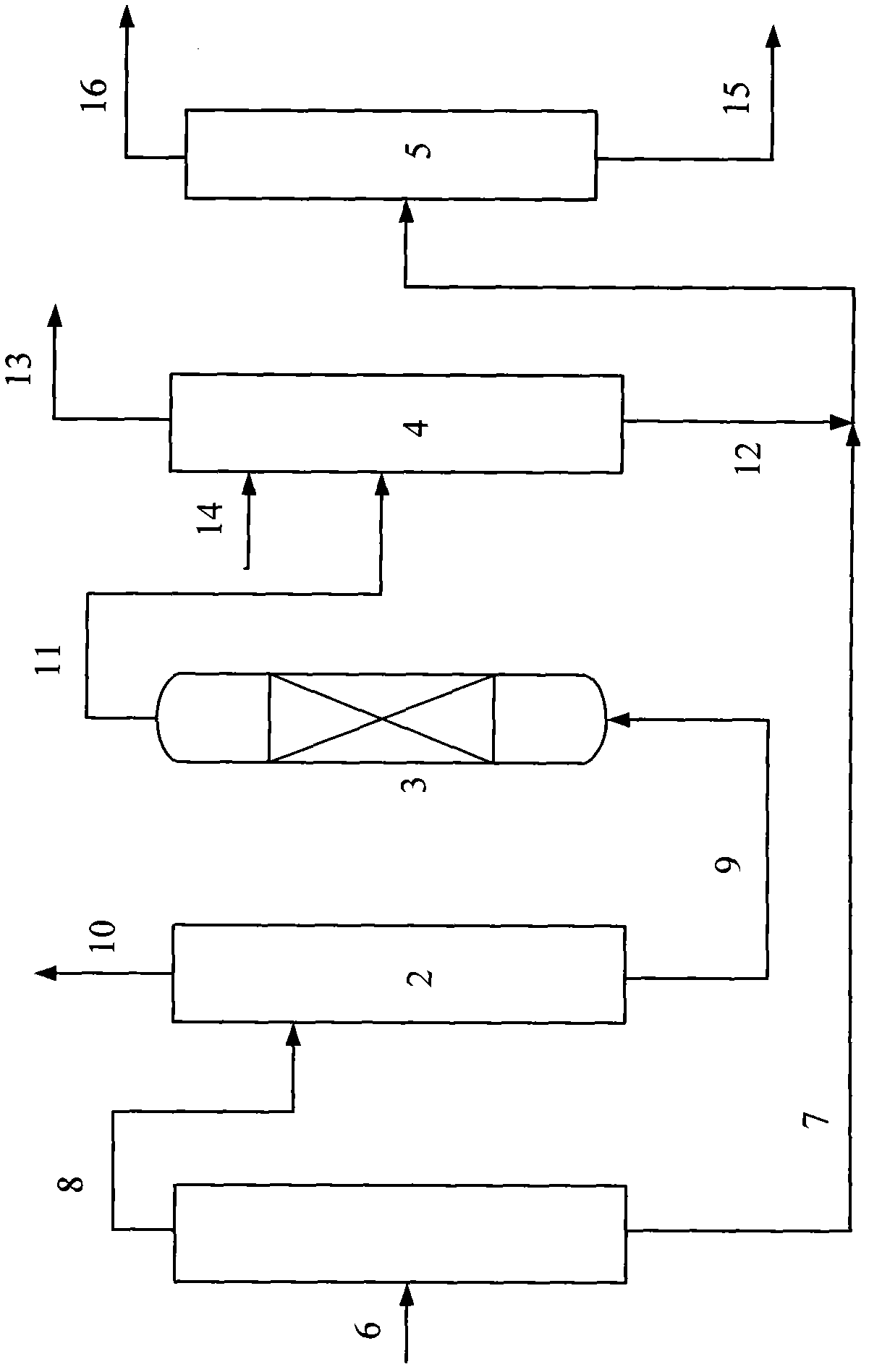

[0019] The present invention provides the refining method of propylene oxide in direct epoxidation reaction product, and direct epoxidation reaction and separation method are specifically implemented like this:

[0020] A method for refining and purifying propylene oxide, comprising:

[0021] The reaction product from the epoxidation reactor enters the propylene separation tower for separation, and the obtained tower top material contains propylene, with or without propane, propylene oxide, methanol, a small amount of aldehyde and ketone impurities, with or without water, and the tower bottom material contains methanol , water, hydrogen peroxide and high-boiling point by-products; the top material of the propylene separation tower enters the propylene stripper, and the top gas contains propylene, with or without propane, and a small amount of propylene oxide, which is recycled to the reaction system after being compressed; The bottom material of the propylene stripper contains...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com