Strontium tantalate nanosphere photocatalyst, as well as preparation method and application thereof

A technology of photocatalysts and nanospheres, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of low degradation efficiency, low activity, and high energy consumption of benzene series pollutants, and achieve high practicality Value and application prospect, high-efficiency degradation, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

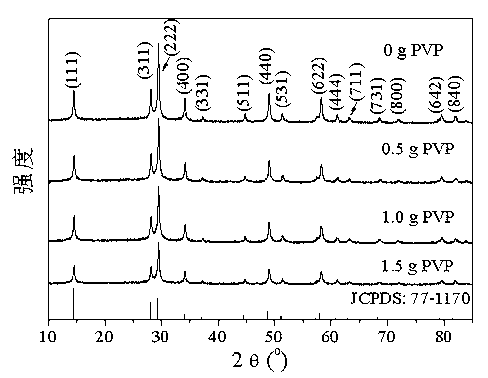

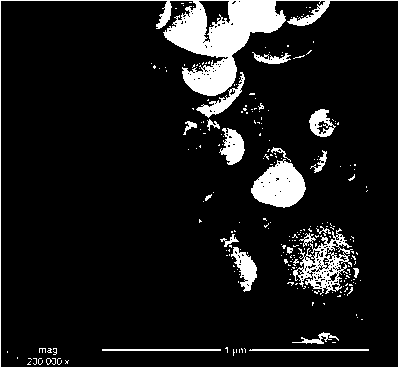

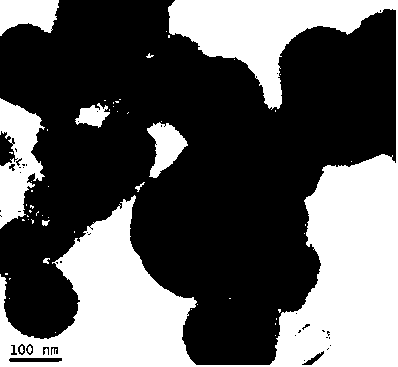

[0022] The first is the preparation of the precursor, weighing 2 g of commercial Ta 2 o 5 dissolved in 30 mL of NH 4 HF 2 In solution, Ta 2 o 5 with NH 4 HF 2 The mass ratio of tantalic acid is 1:2, add ammonia water with a mass fraction of 25% under rapid stirring, adjust the pH value of the solution to not less than 9, until the white tantalic acid precursor precipitates, filter and set aside; in the polytetrafluoroethylene reactor Add 1 g tantalate precursor, Sr(NO 3 ) 2 (The molar ratio of Ta to Sr is 1:1) and 1 g of PVP, then add 70 mL of deionized water and stir rapidly, adjust the pH value to 10 with 4mol / L NaOH solution, and then react hydrothermally at 160°C for 48 h; After natural cooling, washing with ethanol and water, centrifugation, and drying, it becomes the strontium tantalate nanosphere photocatalyst.

Embodiment 2

[0024] The first is the preparation of the precursor, weighing 2 g of commercial Ta 2 o 5 dissolved in 30 mL of NH 4 HF 2 In solution, Ta 2 o 5 with NH 4 HF 2 The mass ratio of tantalic acid is 1:2, add ammonia water with a mass fraction of 25% under rapid stirring, adjust the pH value of the solution to not less than 9, until the white tantalic acid precursor precipitates, filter and set aside; in the polytetrafluoroethylene reactor Add 1 g tantalate precursor, Sr(NO 3 ) 2(The molar ratio of Ta to Sr is 1:1) and 0.5 g of PVP, then add 70 mL of deionized water and stir rapidly, adjust the pH value to 10 with 4 mol / L NaOH solution, and then hydrothermally react at 180 °C for 36 h; After natural cooling, washing with ethanol and water, centrifugation, and drying, it becomes the strontium tantalate nanosphere photocatalyst.

Embodiment 3

[0026] The first is the preparation of the precursor, weighing 2 g of commercial Ta 2 o 5 dissolved in 30 mL of NH 4 HF 2 In solution, Ta 2 o 5 with NH 4 HF 2 The mass ratio of tantalic acid is 1:2, add ammonia water with a mass fraction of 25% under rapid stirring, adjust the pH value of the solution to not less than 9, until the white tantalic acid precursor precipitates, filter and set aside; in the polytetrafluoroethylene reactor Add 1 g tantalate precursor, Sr(NO 3 ) 2 (The molar ratio of Ta to Sr is 1:1) and 1.5 g of PVP, then add 70 mL of deionized water and stir rapidly, adjust the pH value to 10 with 4mol / L NaOH solution, and then hydrothermally react at 160°C for 36 h; After natural cooling, washing with ethanol and water, centrifugation, and drying, it becomes the strontium tantalate nanosphere photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com