Preparation method of macromolecule plasticizer based on recycled cooking oil

A technology of macromolecular plasticizer and waste oil, which is applied in the field of preparation and modification of functional polymer materials, can solve harmful and toxic problems, achieve significant economic benefits, excellent compatibility, and avoid the effect of flowing to the dining table again

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

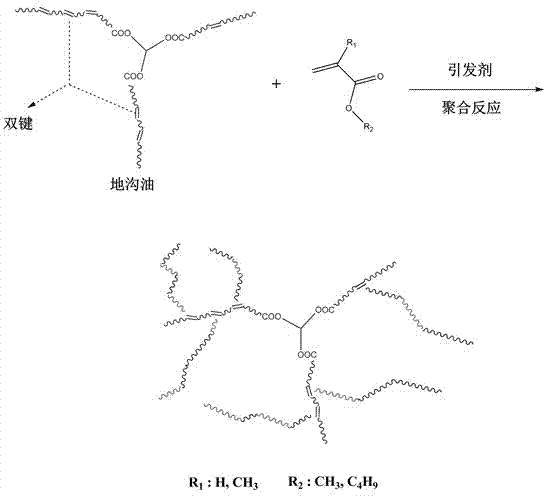

[0030] A kind of preparation method of the macromolecule plasticizer based on waste oil, wherein, comprises the following steps:

[0031] Step 1, washing, decolorizing, filtering, absorbing, and sterilizing the waste oil to obtain purified waste oil whose main chemical composition is unsaturated fatty acid glyceride;

[0032] Step 2, the purified waste oil obtained in step 1 and high polymerization activity monomer, glass transition temperature regulating monomer and PVC similar solubility parameter monomer are mass ratio 5~100: 5~20: 0~100: 0~50 Mix to obtain a mixed solution, add an initiator with a mass ratio of 0% to 15% to the mixed solution, react at a temperature of 0°C to 150°C, and undergo conventional free radical or living free radical polymerization for 1 hour After 10 hours, a macromolecular plasticizer based on waste oil was obtained.

[0033] In an embodiment, the initiator is azobisisobutyronitrile, azobisisoheptanonitrile, dibenzoyl peroxide, dicumyl peroxide...

Embodiment 1

[0046] Add 100 g of ethyl acetate, 100 g of purified waste oil, 10 g of styrene, 50 g of butyl acrylate, 25 g of methyl methacrylate and 10 g of diphenyl peroxide into a three-necked flask with a heating and stirring device. Formyl, after mixing evenly, gradually increase the system temperature to 70°C, after 7 hours of heat preservation reaction, raise the system temperature to 78°C, continue the heat preservation reaction for 2 hours, then cool the system temperature to 40°C, to obtain waste oil based A solution-polymerizable macromolecular plasticizer.

Embodiment 2

[0048] Add 80 g absolute ethanol, 20 g purified water, 100 g purified waste oil, 25 g styrene, 100 g n-octyl acrylate, 50 g methyl acrylate and 20 g Ammonium persulfate, after mixing evenly, gradually raise the system temperature to 75°C, after 8 hours of heat preservation reaction, raise the system temperature to 80°C, continue the heat preservation reaction for 2 hours, then cool the system temperature to 40°C, that is, the trench-based Precipitation polymerization macromolecule plasticizer of oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com