High density ultramicro formation testing working solution and preparation method thereof

An oil testing working fluid, high-density technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of well control risk, excessive gas slippage speed, easy failure of additives, etc., and achieve excellent high temperature subsidence. Effects of stability and rheology, high recycling value, excellent thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

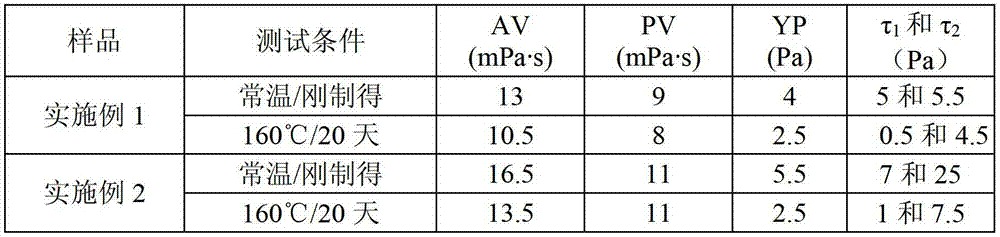

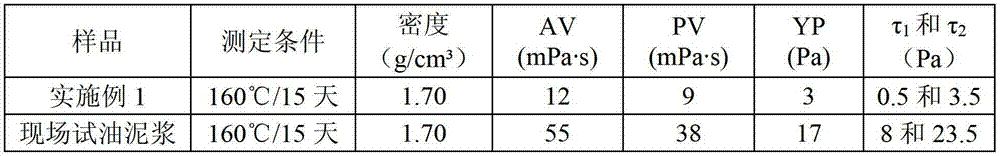

Embodiment 1

[0022] This embodiment provides a density of 1.7g / cm 3 The high-density ultramicro oil test oil working fluid, which is prepared by the following method:

[0023] Put 100m in the preparation tank 3 Fresh water, under high-speed stirring at 8000-12000 rpm, add 0.3t polyacrylate, 0.2t mixture of oleic acid and linoleic acid sodium salt (the two are mixed in any mass ratio), 0.12t sodium hydroxide , 1t of a mixture of sorbitol and polyethylene glycol (the two are mixed in any mass ratio), 0.3t of modified lignosulfonate, 0.2t of low-viscosity PAC, and 17.5t of barite powder to the high-density ultramicro test The density of the oil working fluid reaches 1.7g / cm 3 , after fully stirring and mixing evenly, when the average particle size of the solid phase in the working solution is measured by a laser particle size analyzer (D 50 ) is less than 4 microns (the average particle size of the solid phase is the average particle size of the barite powder), the high-density ultra-micro...

Embodiment 2

[0025] This embodiment provides a density of 2.1g / cm 3 The high-density ultramicro oil test oil working fluid, which is prepared by the following method:

[0026] Put 10m in the high-performance wet mill reactor 3Fresh water, under high-speed stirring at 8000-12000 rpm, add 0.05t of polyacrylate and polyacrylamide salt mixture (the two are mixed in any mass ratio), 0.03t of oleic acid and linoleic acid sodium salt in sequence Mixture (the two are mixed in any mass ratio), 0.012t sodium hydroxide, 0.1t sorbitol and polyethylene glycol mixture (the two are mixed in any mass ratio), 0.05t modified lignosulfonate, 0.01t Low-viscosity PAC, barite powder 2.75t until the density of the high-density ultra-micro test oil test working fluid reaches 2.1g / cm 3 , fully stirred and mixed evenly, when the average particle size of the solid phase in the working fluid is measured by a laser particle size analyzer (D 50 ) is less than 3 microns (the average particle size of the solid phase i...

Embodiment 3

[0028] This embodiment provides a density of 2.3g / cm 3 The high-density ultramicro oil test oil working fluid, which is prepared by the following method:

[0029] Put 10m in the high-performance wet mill reactor 3 Fresh water, under high-speed stirring at 8000-12000 rpm, add 0.08t polyacrylate, 0.04t mixture of oleic acid and linoleic acid sodium salt (the two are mixed in any mass ratio), 0.01t methyl polyacrylate Acrylate, 0.012t sodium hydroxide, 0.1t sorbitol, a mixture of polyethylene glycol and triethanolamine (the three are mixed in any mass ratio), 0.08t modified lignosulfonate, 0.01t low-viscosity PAC and yellow The mixture of raw gum (the two are mixed in any mass ratio), barite powder 3.25t until the density of the high-density ultra-micro test oil test working fluid reaches 2.3g / cm 3 , fully stirred and mixed evenly, when the average particle size of the solid phase in the working fluid is measured by a laser particle size analyzer (D 50 ) is less than 2 microns...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com