Novel cationic liposome nucleic acid pharmaceutical preparation as well as preparation method and application thereof

A technology of cationic liposomes and cationic lipids, which can be used in liposome delivery, other methods of inserting foreign genetic materials, drug combinations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

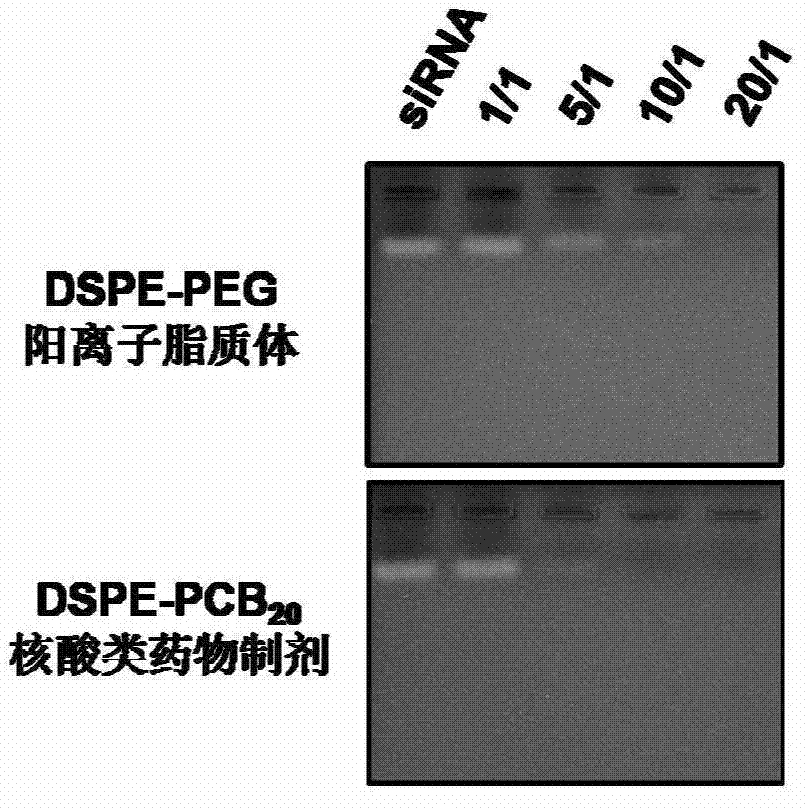

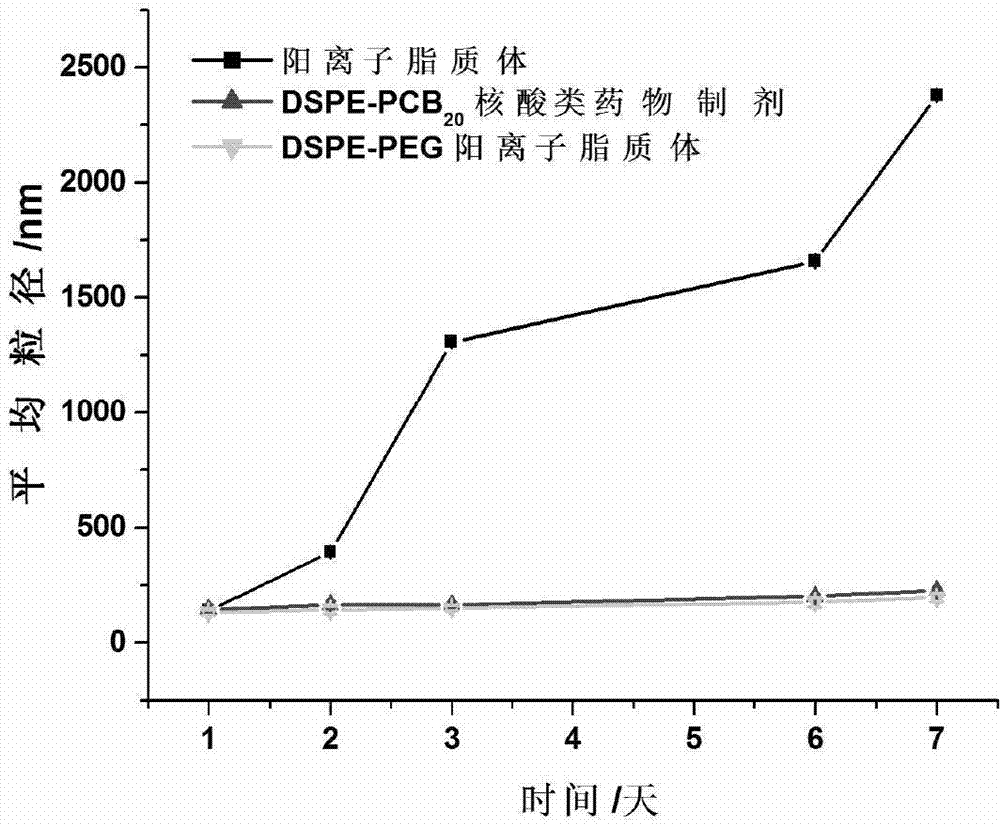

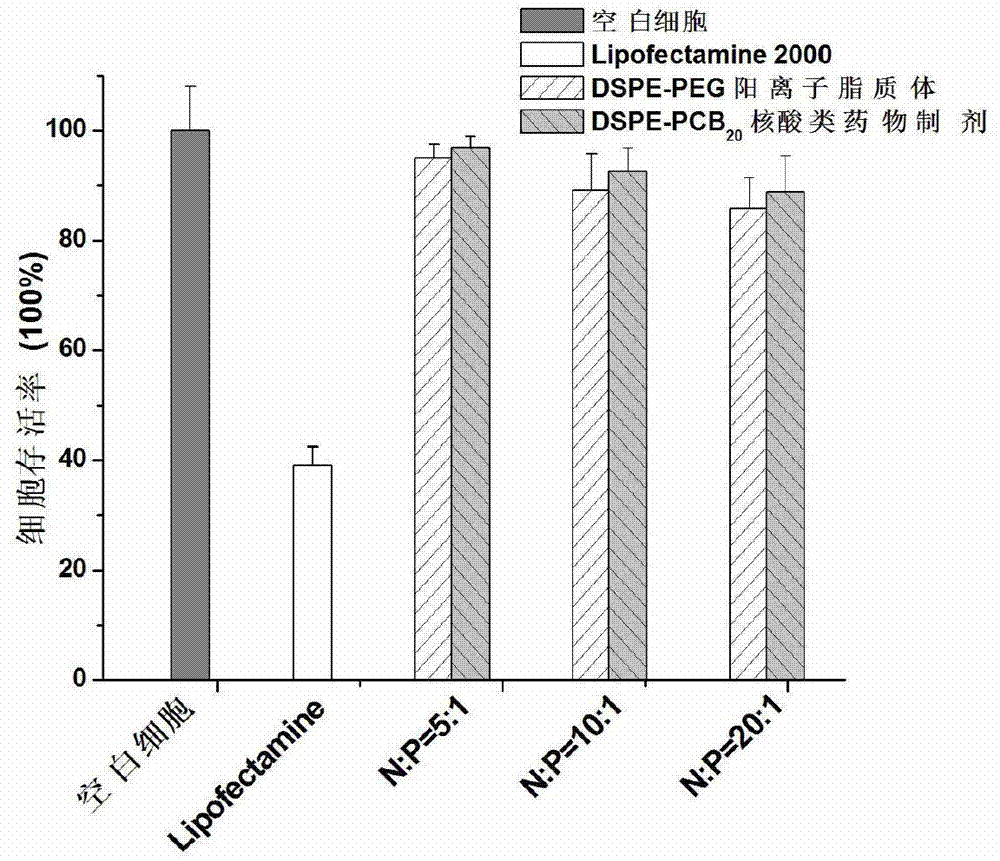

[0062] The preparation of embodiment 1 cationic liposome nucleic acid drug preparation

[0063] 1) Preparation of cationic liposomes: weigh cationic lipid DDAB (9.46 mg, 15 μmol), cholesterol (5.80 mg, 15 μmol) and DSPE-PCB 20 (32.86mg, 6μmol) in a 100mL round bottom flask, add 30mL of chloroform to fully dissolve the solid, shake well. Using a rotary evaporator at a rotational speed of 140 rpm and a temperature of 55° C., the solvent chloroform was removed by rotary evaporation under reduced pressure to form a thin oil film, which was dried with a vacuum pump for 12 hours to ensure that the chloroform was completely removed. Add 30 mL of phosphate buffer saline (PBS, pH=7.4) containing 10% lactose to the flask, and use an ultrasonic cleaner to ultrasonicate for 30 min at a frequency of 90% to form a translucent emulsion. The emulsion is added to a high-pressure homogenizer, and under the condition of a pressure of 100 MPa, overpressure is performed 5 times. Add the emulsion...

Embodiment 2

[0066] The preparation of embodiment 2 cationic liposome nucleic acid drug preparation

[0067] 1) Preparation of cationic liposomes: weigh cationic lipid DDAB (4.73 mg, 7.5 μmol), cholesterol (5.80 mg, 15 μmol) and DSPE-PCB 10 (16.83mg, 6μmol) in a 100mL round bottom flask, add 30mL of chloroform to fully dissolve the solid, shake well. Using a rotary evaporator at a rotational speed of 100 rpm and a temperature of 40°C, the solvent chloroform was removed by rotary evaporation under reduced pressure to form a thin oil film, which was dried with a vacuum pump for 6 hours to ensure that the chloroform was completely removed. Add 10 mL of phosphate buffer saline (PBS, pH=7.4) containing 5% lactose to the flask, and use an ultrasonic cleaner to ultrasonicate for 15 minutes at a frequency of 50% to form a translucent emulsion. Add the emulsion into a high-pressure homogenizer, and under the condition of a pressure of 50 MPa, overpressure 3 times. Add the emulsion into the liposo...

Embodiment 3

[0070]The preparation of embodiment 3 cationic liposome nucleic acid drug preparation

[0071] 1) Preparation of cationic liposomes: weigh cationic lipid DDAB (9.46 mg, 15 μmol), cholesterol (5.80 mg, 15 μmol) and DSPE-PCB 20 (16.43mg, 3μmol) in a 100mL round bottom flask, add 30mL of chloroform to fully dissolve the solid, shake well. Using a rotary evaporator at a rotational speed of 200 rpm and a temperature of 80°C, the solvent chloroform was removed by rotary evaporation under reduced pressure to form a thin oil film, which was dried with a vacuum pump for 36 hours to ensure that all chloroform was removed. Add 15 mL of phosphate buffered saline (PBS, pH=7.4) containing 20% maltose to the flask, and use an ultrasonic cleaner to sonicate for 1 hour at a frequency of 150% to form a translucent emulsion. Add the emulsion into a high-pressure homogenizer, and under the pressure of 150MPa, overpressurize 10 times. Add the emulsion into the liposome extruder, under the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com