Application of sulfonated lignin in wood fibre material enzyme hydrolysis saccharification

A technology for lignocellulosic raw material and sulfonated lignin, which is applied in the field of enzyme engineering, can solve the problems of increasing additional costs and the like, and achieves the effects of reducing the amount of enzymes, easy preparation and easy acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

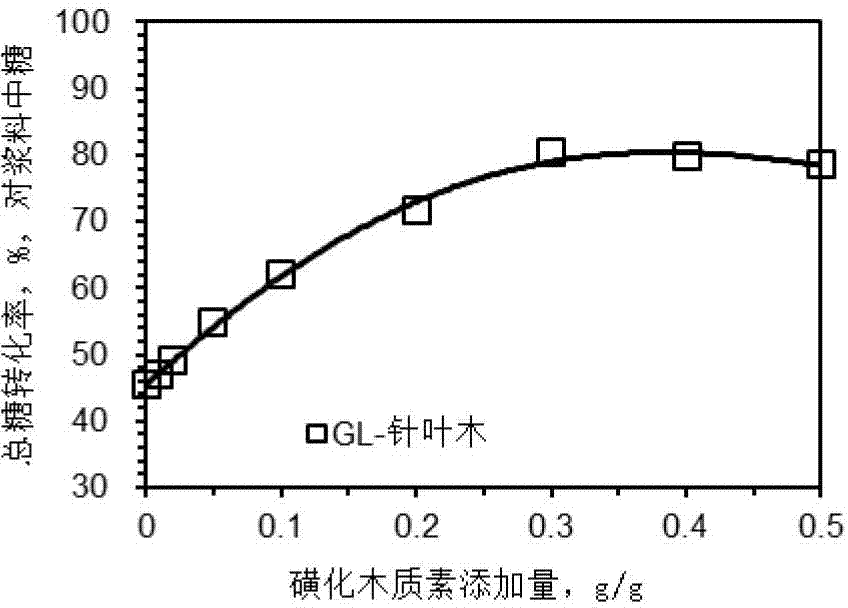

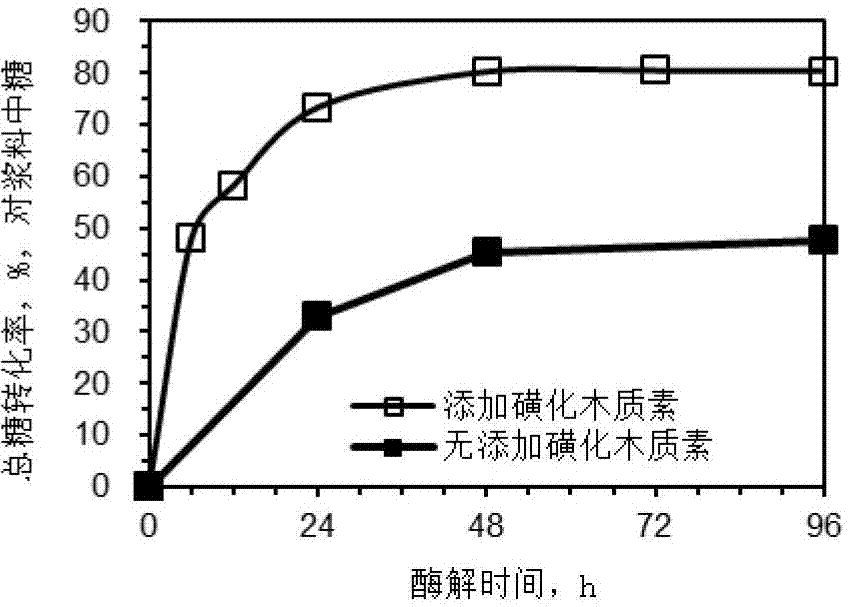

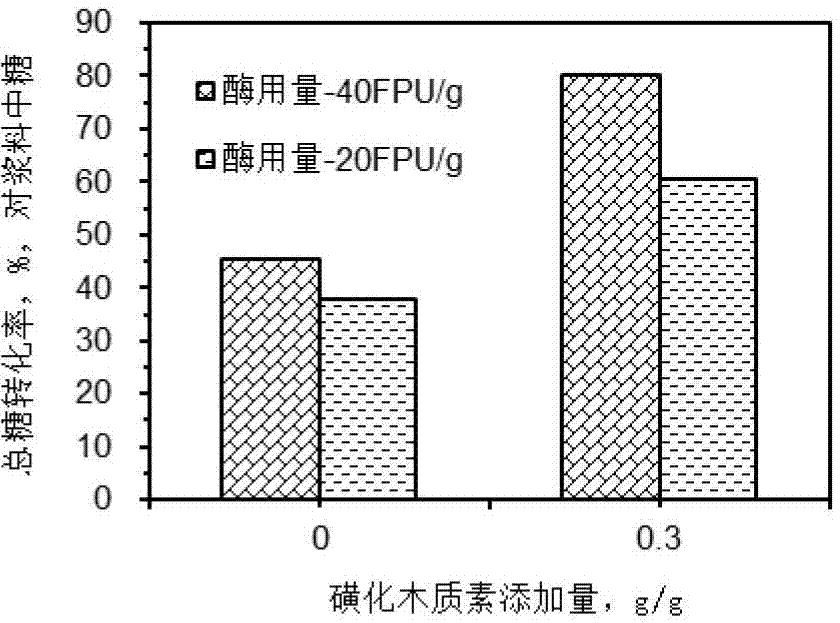

[0053] Embodiment 1: Pretreatment and enzymatic hydrolysis method using coniferous wood as raw material.

[0054] raw material:

[0055] The coniferous wood used in the experiment was produced in Fujian and provided by a paper mill in Fujian. The wood chips are about 1.5cm long, 2.5cm wide and 0.3cm thick. After air drying, balance the moisture for later use.

[0056] The mixed enzyme solution for enzymatic hydrolysis is composed of cellulase, xylanase and β-cellobiase. The enzyme activity ratio per unit volume of the three enzymes is cellulase: xylanase: β-cellobiase = 1FPU: 1.2FXU: 1CBU. The enzyme activity of the mixed enzyme solution is 20 FPU / ml based on the enzyme activity of cellulase filter paper.

[0057] Green liquor pretreatment process:

[0058] Green liquor comes from the alkali recovery system of kraft pulping and is mainly composed of sodium carbonate and sodium sulfide. In a self-made 10×1L oil bath, weigh 150g air-dried wood chips equivalent to absolute ...

Embodiment 2

[0074] Embodiment 2: Pretreatment and enzymatic hydrolysis method using hardwood as raw material.

[0075] raw material:

[0076] The hardwood used in the experiment was produced in northern Jiangsu. The wood chips are about 1.5cm long, 2.5cm wide and 0.2cm thick. After air drying, balance the moisture for later use.

[0077] The mixed enzyme solution for enzymatic hydrolysis is prepared by mixing cellulase, xylanase and β-cellobiase. The enzyme activity ratio per unit volume of the three enzymes is cellulase: xylanase: β-cellobiase = 1FPU: 1.2FXU: 1CBU. The enzyme activity of the mixed enzyme solution is 20 FPU / ml based on the enzyme activity of cellulase filter paper.

[0078] Green liquor pretreatment process:

[0079] Green liquor comes from the alkali recovery system of kraft pulping and is mainly composed of sodium carbonate and sodium sulfide. In a self-made 10×1L oil bath, weigh 150g air-dried wood chips equivalent to absolute dryness in each tank, add the cookin...

Embodiment 3

[0093] Embodiment 3: Pretreatment and enzymatic hydrolysis method using gramineous plants as raw materials.

[0094] raw material:

[0095] The gramineous plant Nandi used in the experiment was produced in Hunan. Cut the ingredients to about 3cm in length, air-dry and balance the moisture for later use.

[0096] The mixed enzyme solution for enzymatic hydrolysis is prepared by mixing cellulase, xylanase and β-cellobiase. The enzyme activity ratio per unit volume of the three enzymes is cellulase: xylanase: β-cellobiase = 1FPU: 1.2FXU: 1CBU. The enzyme activity of the mixed enzyme solution is 20 FPU / ml based on the enzyme activity of cellulase filter paper.

[0097] Green liquor pretreatment process:

[0098] Green liquor comes from the alkali recovery system of kraft pulping and is mainly composed of sodium carbonate and sodium sulfide. In a self-made 10×1L oil bath, weigh 100g of air-dried wood chips equivalent to dryness in each tank, add the cooking liquid with a solid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com