Transition metal doped ZnO-based ferromagnetic polycrystalline thin film and preparation method thereof

A technology of transition metals and transition metal elements, which is applied in the field of preparation of dilute magnetic semiconductor polycrystalline thin films, can solve the problems of high resistivity, difficult application of spin devices, unstable ferromagnetic phenomena, etc., and achieve stable magnetic properties, The effect of adjustable thickness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

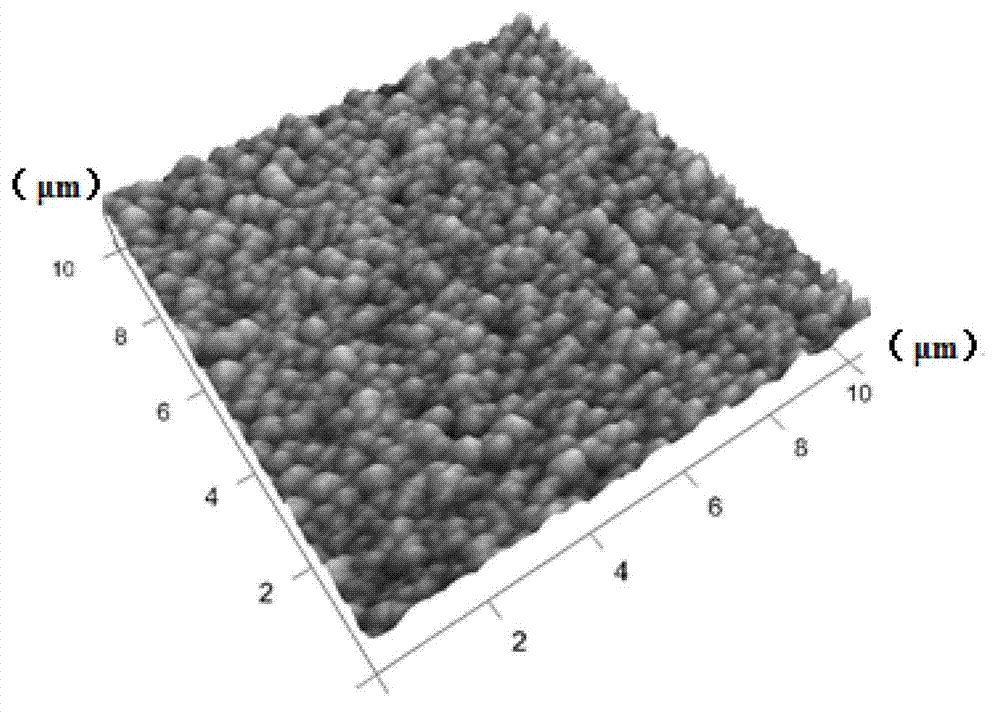

Embodiment 1

[0046] 1) 0.4914g Zn(CH 3 COO) 2 , 0.0103g Cu(CH 3 COO) 2 The powder was dissolved in 30mL and 20mL methanol solutions respectively, and both were refluxed in a water bath at 80°C for 60 minutes to obtain Zn(CH 3 COO) 2 and Cu(CH 3 COO) 2 The precursor solution;

[0047] 2) Add 10mL of 0.2mol / L KOH methanol solution dropwise to the Zn(CH 3 COO) 2 In the precursor solution, add Cu(CH 3 COO) 2 Add the precursor solution to the above solution, after the temperature drops to 60°C, add 10mL of 0.235mol / L KOH methanol solution, and keep the reaction at 60°C for 120 minutes to obtain 2.0% Cu-doped ZnO nanocrystal product;

[0048] 3) The reaction was terminated by cooling with ice water, pre-washed by methanol centrifugation for 3 times, and then the precipitate was dispersed in 20 mL of n-octylamine in an amine bath at 50 °C for 60 minutes, and the purified Cu-doped ZnO nanocrystal precipitate was obtained by centrifugation;

[0049] 4) Add 10 mL of chloroform to the abov...

Embodiment 2

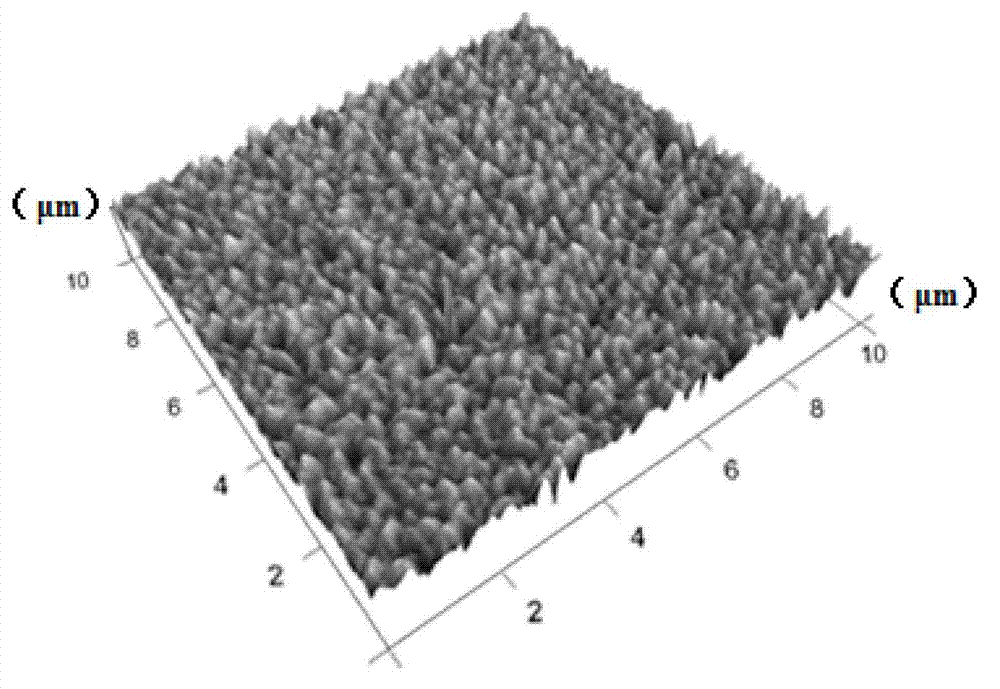

[0054] 1) 0.4914g Zn(CH 3 COO) 2 , 0.0396g Co(CH 3 COO) 2 The powder was dissolved in 20mL and 10mL methanol solutions respectively, and both were refluxed in a water bath at 65°C for 120 minutes to obtain Zn(CH 3 COO) 2 and Co(CH 3 COO) 2 The precursor solution;

[0055] 2) Add 20mL of 0.4mol / L KOH methanol solution dropwise to the Zn(CH 3 COO) 2 In the precursor solution, add Co(CH 3 COO) 2 Add the precursor solution of the above solution to the above solution, after the temperature drops to 50°C, add 20mL of 0.4mol / L KOH methanol solution, and keep the reaction at 50°C for 210 minutes to obtain 6.0% Co-doped ZnO nanocrystal product;

[0056] 3) Stop the reaction by cooling with ice water, pre-wash with methanol for 5 times, then disperse the precipitate into 30 mL of n-octylamine in an amine bath at 50°C for 90 minutes, and centrifuge to obtain the purified Co-doped ZnO nanocrystal precipitate;

[0057] 4) Add 15 mL of chloroform to the nanocrystal precipitate pr...

Embodiment 3

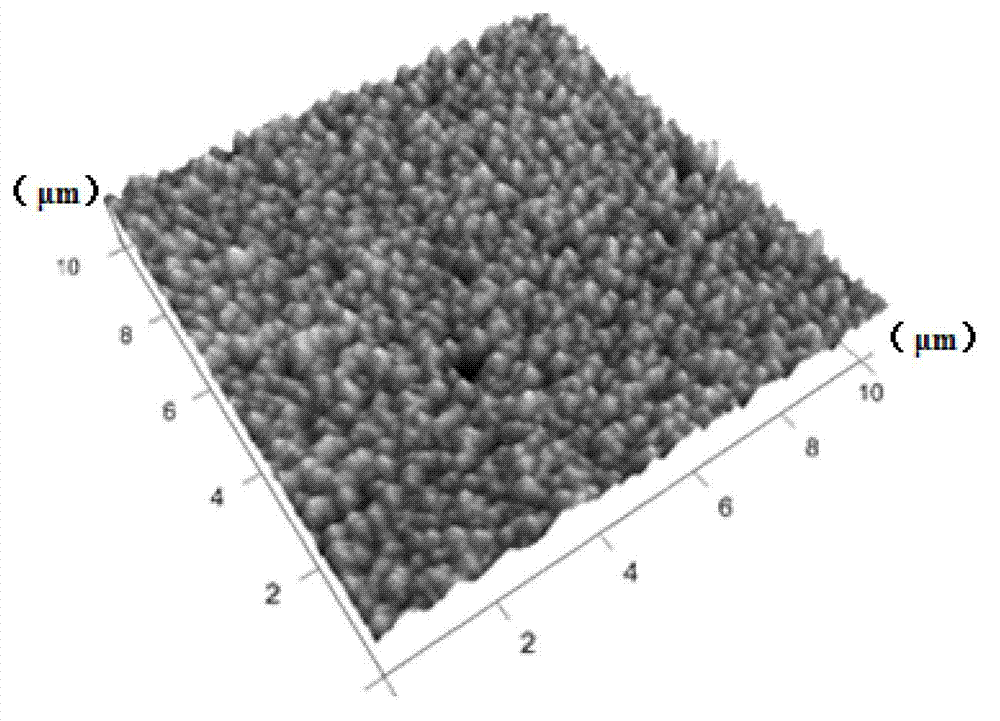

[0062] 1) 0.4914g Zn(CH 3 COO) 2 , 0.0194g Mn(CH 3 COO) 2 The powder was dissolved in 20mL and 10mL methanol solutions respectively, and both were refluxed in a water bath at 70°C for 80 minutes to obtain Zn(CH 3 COO) 2 and Mn(CH 3COO) 2 The precursor solution;

[0063] 2) Add 20mL of 0.3mol / L KOH methanol solution dropwise to the Zn(CH 3 COO) 2 In the precursor solution, add Mn(CH 3 COO) 2 Add the precursor solution to the above solution, after the temperature drops to 50°C, add 20mL of 0.3mol / L KOH methanol solution, and keep the reaction at 50°C for 150 minutes to obtain 4.0% Mn-doped ZnO nanocrystal product;

[0064] 3) Stop the reaction by cooling with ice water, pre-wash with methanol for 5 times, then disperse the precipitate into 20 mL of n-octylamine in an amine bath at 50°C for 60 minutes, and centrifuge to obtain the purified Mn-doped ZnO nanocrystal precipitate;

[0065] 4) Add 10 mL of chloroform to the nanocrystal precipitate prepared above to fully di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com