Method for preparing gold nano-rods

A technology of gold nanorods and gold species, which is applied in the field of synthesis of nanomaterials, can solve the problems of difficult to obtain high-yield gold nanorods, small-sized gold nanorods with high yield, large size of gold nanorods, etc., and achieve low production cost , good reproducibility and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

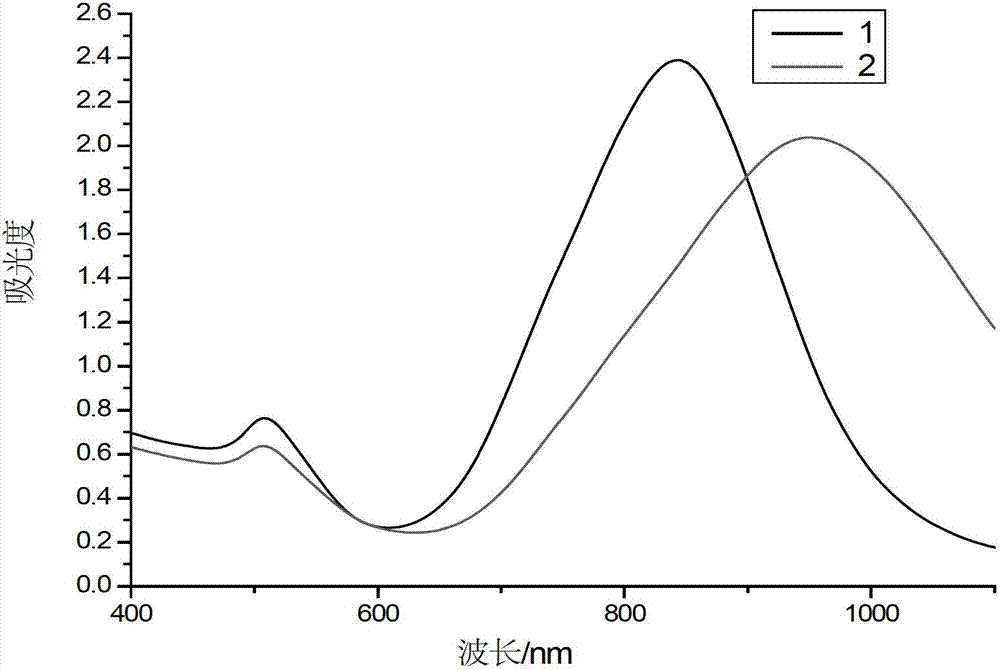

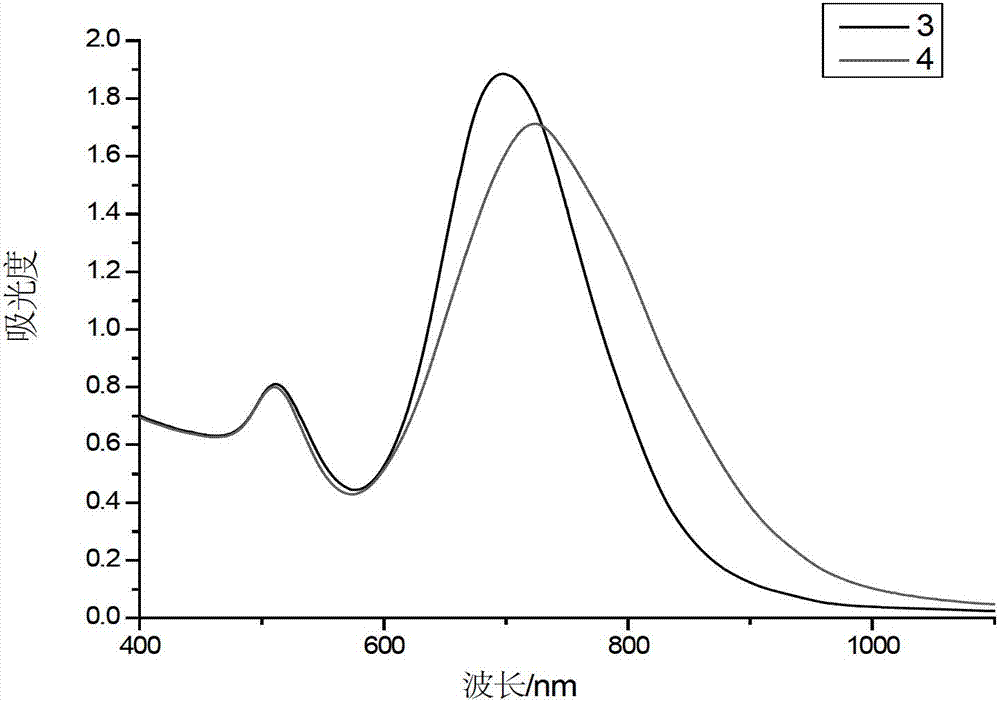

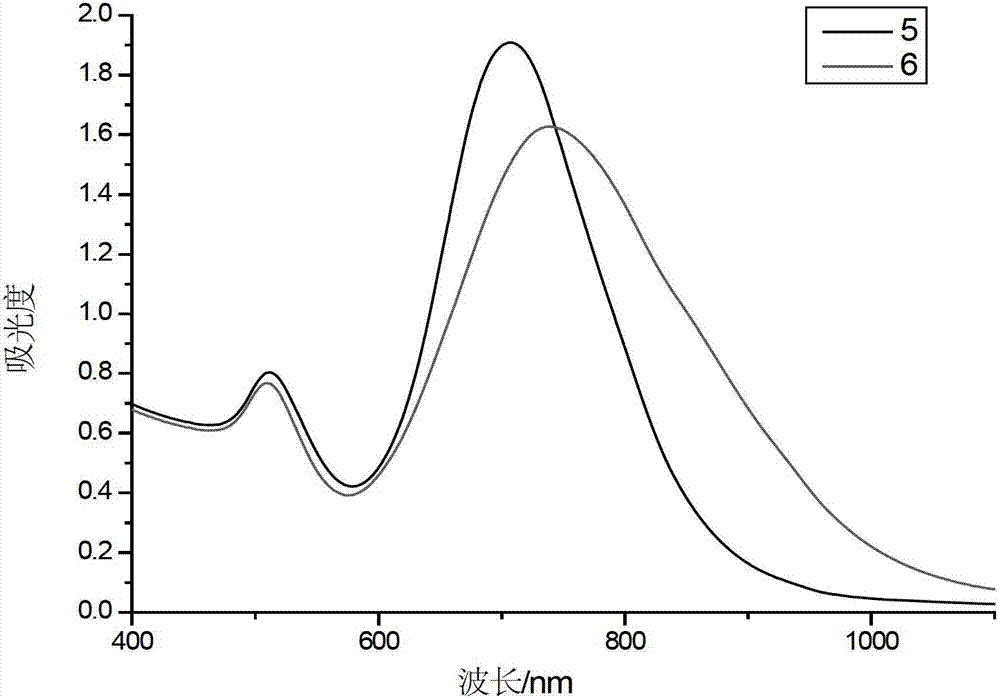

Image

Examples

preparation example Construction

[0043] A preparation method of gold nanorods, comprising the steps of:

[0044] 1) Add chloroauric acid solution and an optional gold species formation regulator to CTAB solution, then add silver nitrate solution, weak reducing agent and strong reducing agent, and react at a constant temperature of 25-40°C for 5-30 minutes to obtain reaction solution A;

[0045] 2) Adding at least one of the silver nitrate solution and the gold nanorod growth regulator solution to the reaction solution A to obtain the reaction solution B, and continue the reaction to obtain the gold nanorods.

[0046] Preferably, in the reaction solution A, the final concentration of CTAB is 0.06-0.12 M, and the final concentration of chloroauric acid is 0.04-0.08 mM.

[0047] Preferably, the reaction solution B is transferred to a constant temperature environment of 15-90° C., and the gold nanorods are grown for 0.1-24 hours.

[0048] The gold seed generation regulator is selected from sodium chloride, C 3~8 ...

Embodiment 1

[0056] Take 5mL 0.1M CTAB (containing 6.8mg NaCl) in a 25mL beaker, add 500μL chloroauric acid solution to the beaker, add 32.5μL silver nitrate solution, 50μL ascorbic acid solution, stir, then add 3μL sodium borohydride solution , transferred to a water bath at 30°C for 11 minutes, added 5 mL of deionized water, 32.5 μL of silver nitrate solution, and 5 μL of heterogeneous crystal nucleus ZnO during stirring, and transferred to a 22°C cooling cycle tank for growth for 24 hours.

Embodiment 2

[0058] Example 2 is similar to Example 1, except that after a 30°C water bath, the amount of silver nitrate solution is changed to 40 μL, the heterogeneous crystal nucleus is changed to 0.1M aluminum sulfate solution, and other conditions remain unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com