Solar energy mono-crystalline silicon piece flocking solution and application method thereof

A technology of monocrystalline silicon wafer and application method, which is applied in the field of texturing liquid, can solve the problems of reducing the passivation effect, reducing the lifetime of minority carriers, and large size differences, so as to achieve good passivation effect of the textured surface, reduce the density of defect states, The effect of fewer surface defect states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The texturing liquid for solar cell monocrystalline silicon wafers in the present embodiment has the following components: the proportion of alkaline reagent NAOH is 9.6g / L, the ethanol content is 50ml / L, sodium ethylate 0.3g / L, vitamin 1g / L and 0.5g / L perfluoroalkyl ether carboxylate potassium salt FC-5, polyoxyethylene ether, polyethylene glycol ester, polyol ester or lauroyl diethanolamine.

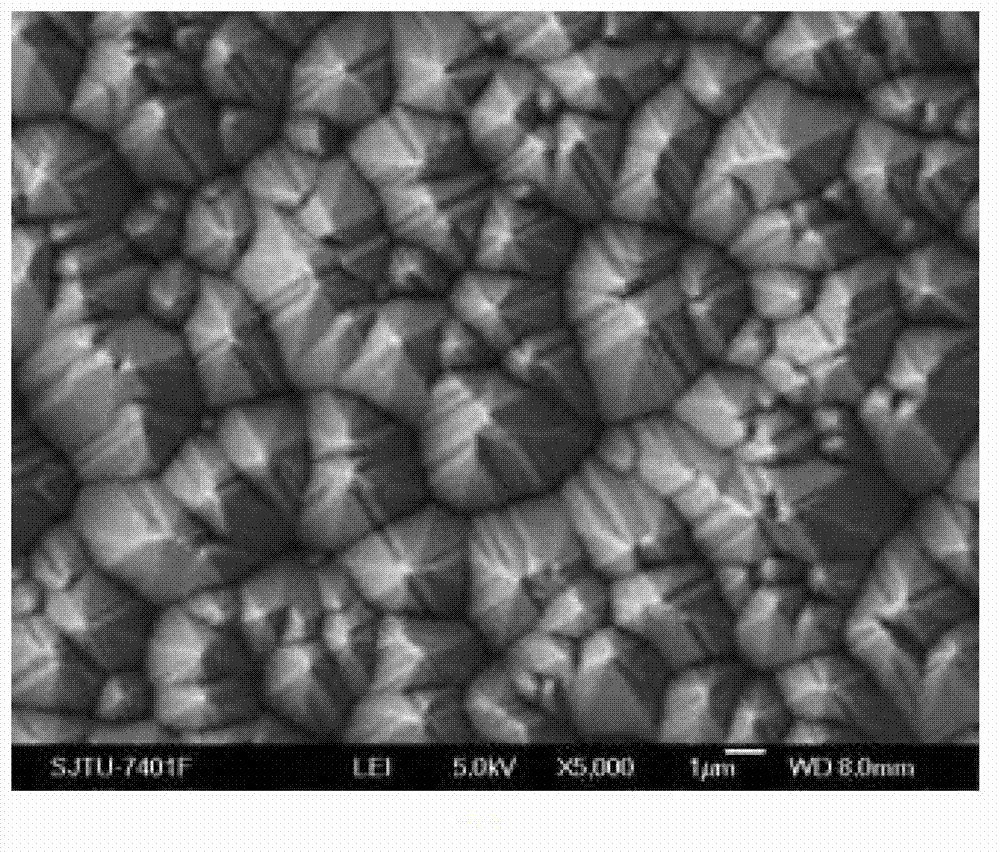

[0022] Put the above proportioned texturing solution in a water bath and control the temperature at 78-80°C, place the cleaned silicon chip in it for 30 minutes, take it out, wash and dry it, observe it with a scanning electron microscope, and get the following: figure 1 Pyramid suede SEM shown.

[0023] The silicon wafers are ultrasonically cleaned and polished.

Embodiment 2

[0025] The texturing liquid for solar cell monocrystalline silicon wafers in the present embodiment has the following components: the proportion of alkaline reagent NAOH is 11.2g / L, the ethanol content is 80ml / L, sodium ethylate 1g / L, and vitamin 1.3g / L and 1g / L perfluoroalkyl ether carboxylate potassium salt FC-5, polyoxyethylene ether, polyethylene glycol ester, polyol ester or lauroyl diethanolamine.

[0026] Put the texturing solution with the above ratio in a water bath and control the temperature at 78-80°C, place the cleaned silicon wafer in it for 30 minutes of corrosion, take it out, wash and dry it.

[0027] The silicon wafers are ultrasonically cleaned and polished.

Embodiment 3

[0029] The texturizing liquid for solar cell monocrystalline silicon wafers in the present embodiment has the following components: the proportion of alkaline reagent NAOH is 12.5g / L, the ethanol content is 100ml / L, sodium ethylate 2g / L, vitamin 2g / L L and 2.5g / L perfluoroalkyl ether carboxylate potassium salt FC-5, polyoxyethylene ether, polyethylene glycol ester, polyol ester or lauroyl diethanolamine.

[0030] Put the texturing solution with the above ratio in a water bath and control the temperature at 78-80°C, place the cleaned silicon wafer in it for 30 minutes of corrosion, take it out, wash and dry it.

[0031] The silicon wafers are ultrasonically cleaned and polished.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com