Method for preparing lithium iron phosphate/carbon composite material by using aniline

A technology of carbon composite materials and lithium iron phosphate, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of shortening Li+ diffusion path and inability to effectively improve the electronic conductivity of materials, and achieve the effect of improving electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

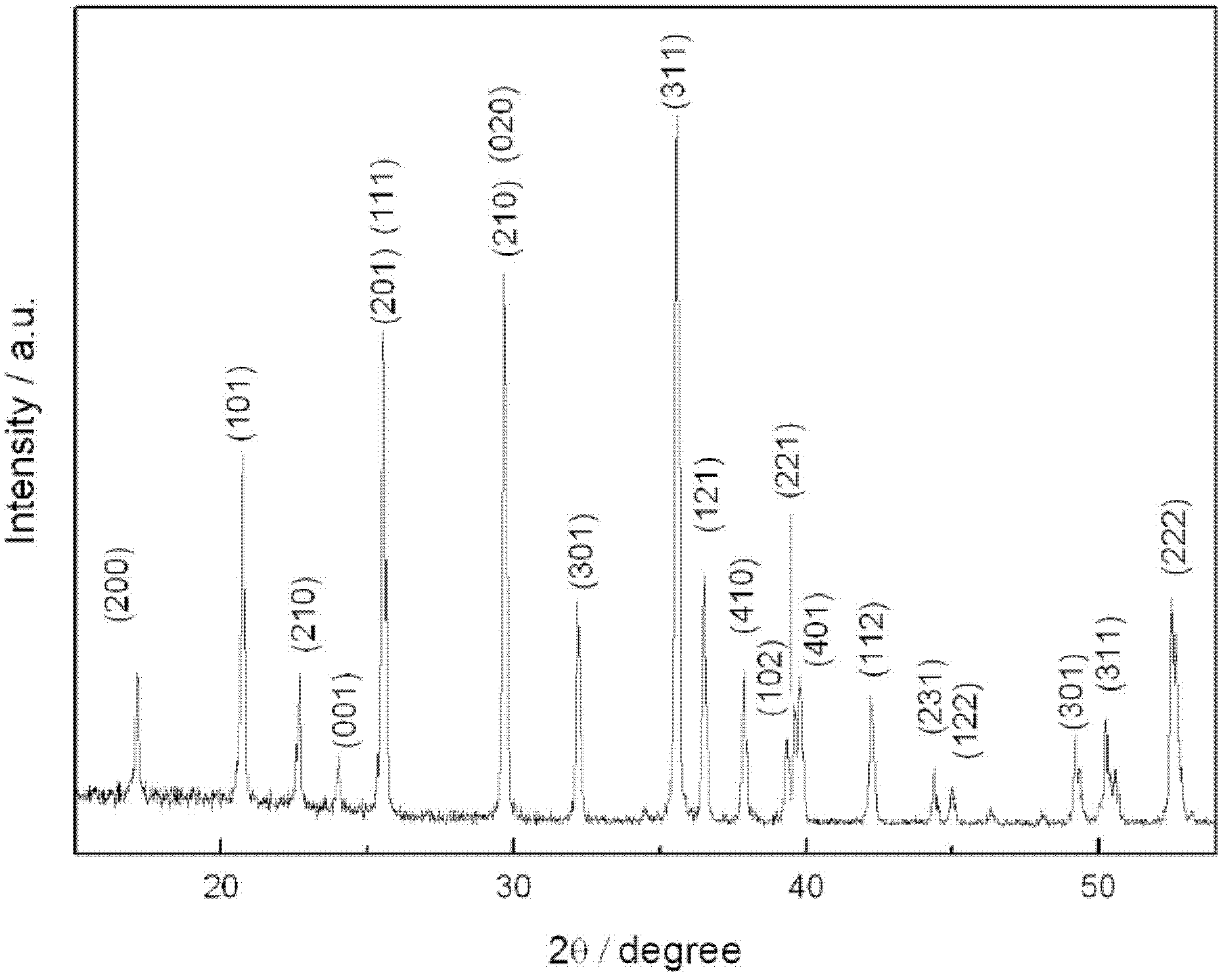

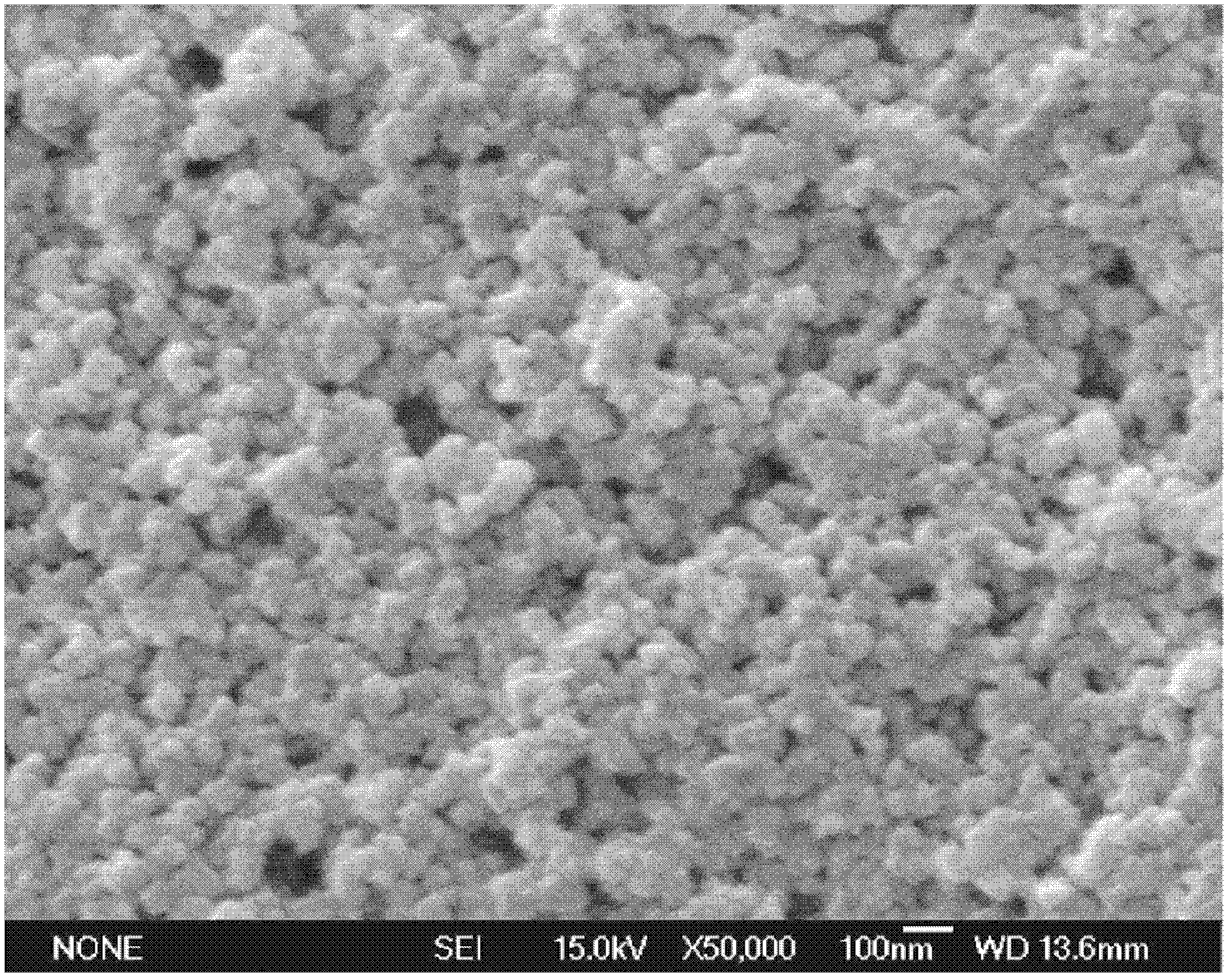

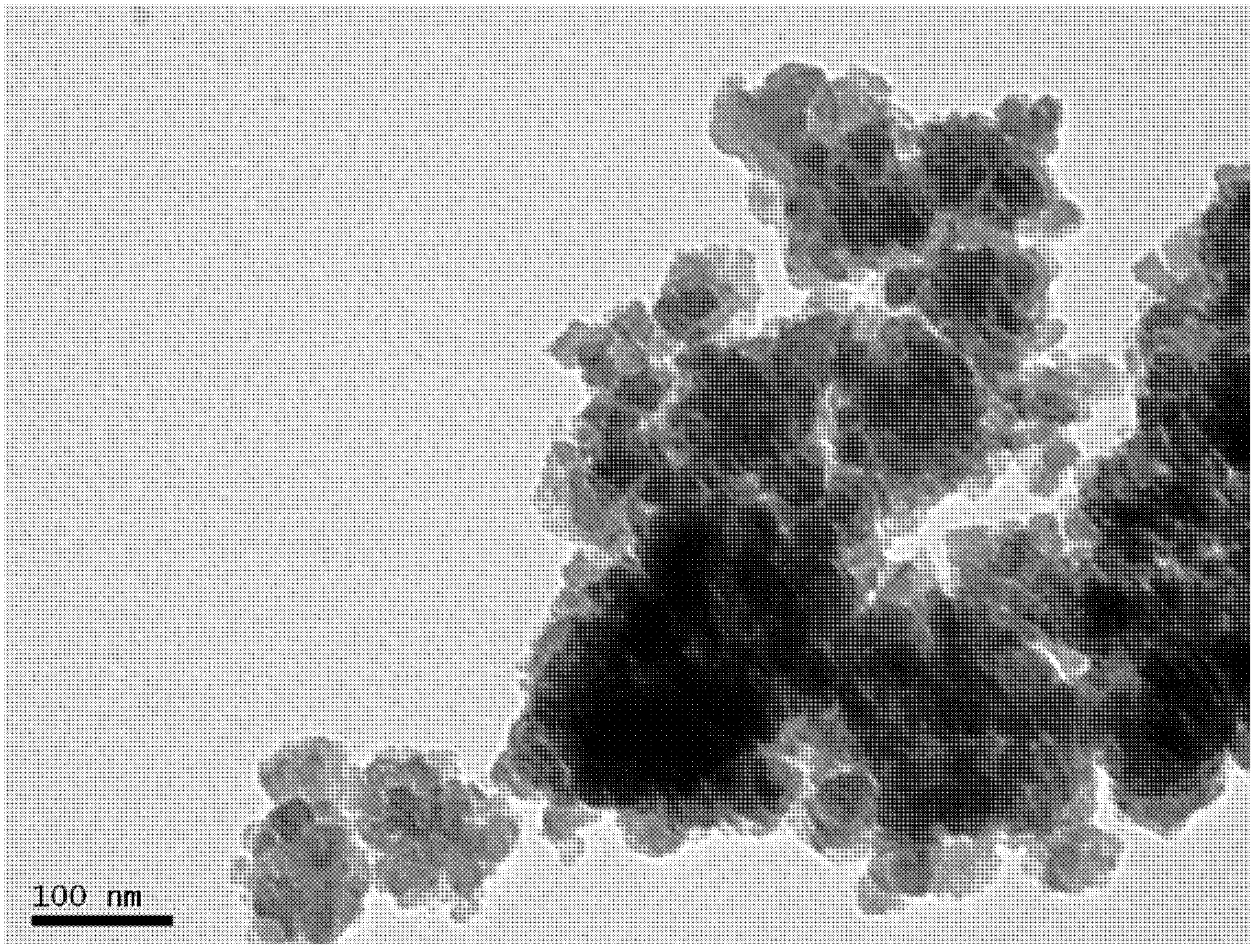

[0019] Weigh 2.62 grams of ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) and 3.73 grams of ferric chloride (FeCl 3 ) and were dissolved in 250mL and 125mL of deionized water respectively, and 1.0 milliliter (mL) of aniline was added dropwise to NH 4 h 2 PO 4 solution and stirred to make it evenly dispersed; then, the FeCl3 solution was slowly added dropwise to the NH4H2PO4 solution containing aniline. Stir the above mixed solution at room temperature for 5 hours to generate the iron phosphate / polyaniline precursor, wash the iron phosphate / polyaniline several times with deionized water and centrifuge each time, put the obtained iron phosphate / polyaniline precipitate into In a blast oven, dry at 80° C. (Celsius) for 4 hours. The dried material was ground into powder, placed in a tube furnace at a heating rate of 5°C / min (Celsius / minute), under a protective atmosphere, annealed at 400°C for 6 hours, and then cooled naturally to obtain crystallized water and polymer Anilin...

Embodiment 2

[0025] Weigh 5.52 grams of phosphoric acid (H3PO4) and 5.31 grams of ferric nitrate (Fe(NO3)3) with a concentration of 38% and dissolve them in 400 mL and 200 mL of deionized water respectively, add 0.5 mL of aniline dropwise to the H3PO4 solution and stir to make The uniform dispersion; then, the Fe (NO3) 3 solution is slowly added dropwise to the H3PO4 solution containing aniline. Stir the above mixed solution at room temperature for 3 hours to generate the iron phosphate / polyaniline precursor, wash the iron phosphate / polyaniline several times with deionized water and centrifuge each time, put the obtained iron phosphate / polyaniline precipitate into Dry in a blast oven at 80°C for 5 hours. Grind the dried material into powder, place it in a tube furnace at a heating rate of 10°C / min, and under the protection of nitrogen atmosphere, anneal at 300°C for 5 hours and then cool naturally to remove crystal water and pyrolyze polyaniline Carbonized FePO4 / C.

[0026] Dissolve 1.51...

Embodiment 3

[0029] Weigh 2.17 grams of diammonium hydrogen phosphate ((NH4)2HPO4) and 4.38 grams of ferric citrate and dissolve them in 200 mL and 100 mL of deionized water respectively, add 1.5 mL of aniline dropwise into the H3PO4 solution and stir to make it evenly dispersed; then , The ferric citrate solution was slowly added dropwise to the (NH4)2HPO4 solution containing aniline. Stir the above mixed solution at room temperature for 4 hours to generate the iron phosphate / polyaniline precursor, wash the iron phosphate / polyaniline precursor several times with deionized water and centrifuge each time, and precipitate the obtained iron phosphate / polyaniline Put it into a blast oven and dry at 80°C for 3 hours. The dried material is ground into powder, placed in a tube furnace at a heating rate of 15°C / min, under the protection of nitrogen atmosphere, annealed at 500°C for 4 hours and then cooled naturally to obtain crystal water and polyaniline is pyrolyzed Carbonized FePO4 / C.

[0030]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com