Nano-power battery composed of lithium manganate and graphene and preparation method thereof

A power battery and graphene technology, applied in the manufacture of electrolyte batteries, secondary batteries, non-aqueous electrolyte batteries, etc., can solve the problems of poor safety, short service life, low power, etc., and achieve stable internal structure, short service life, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

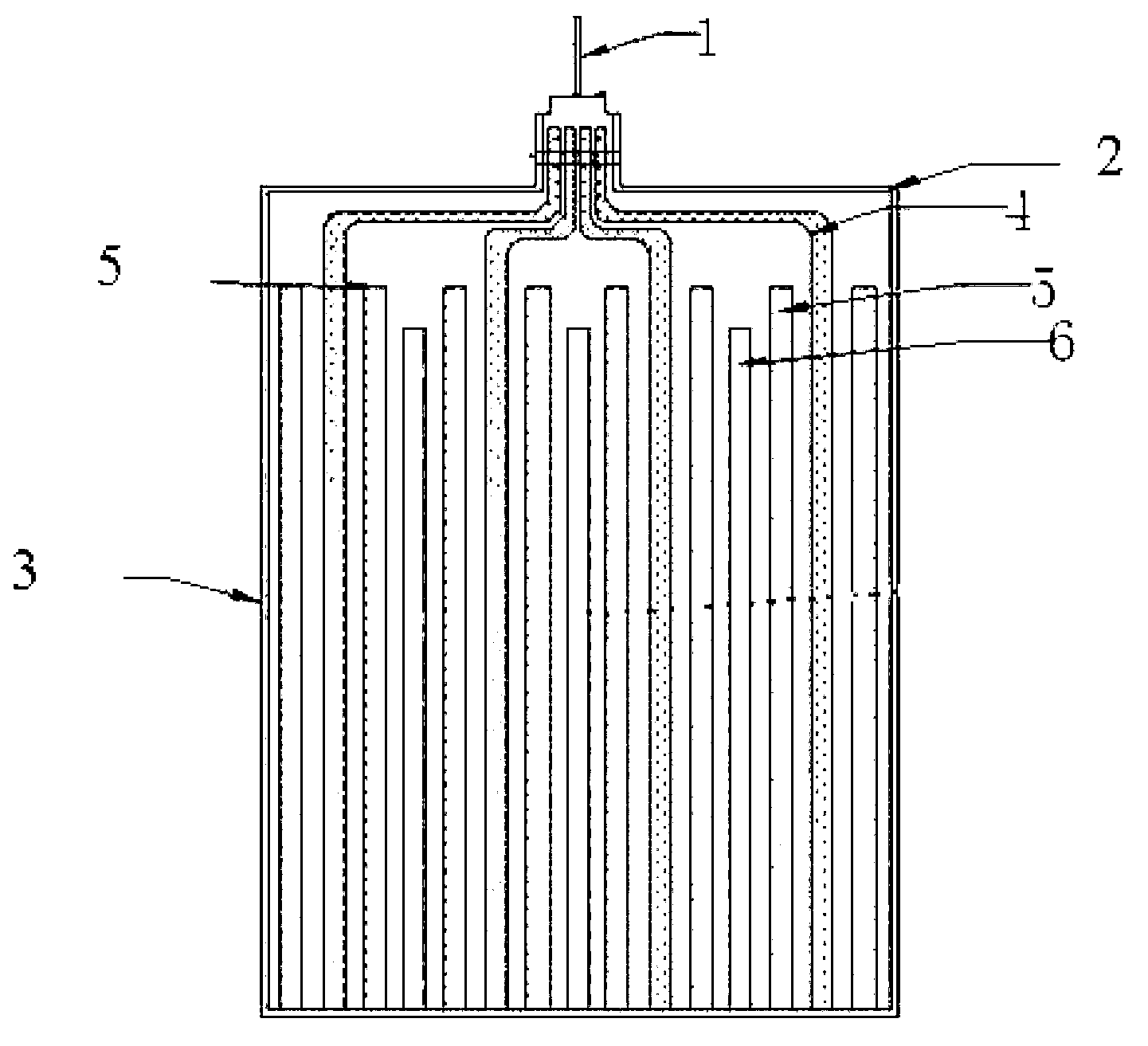

Image

Examples

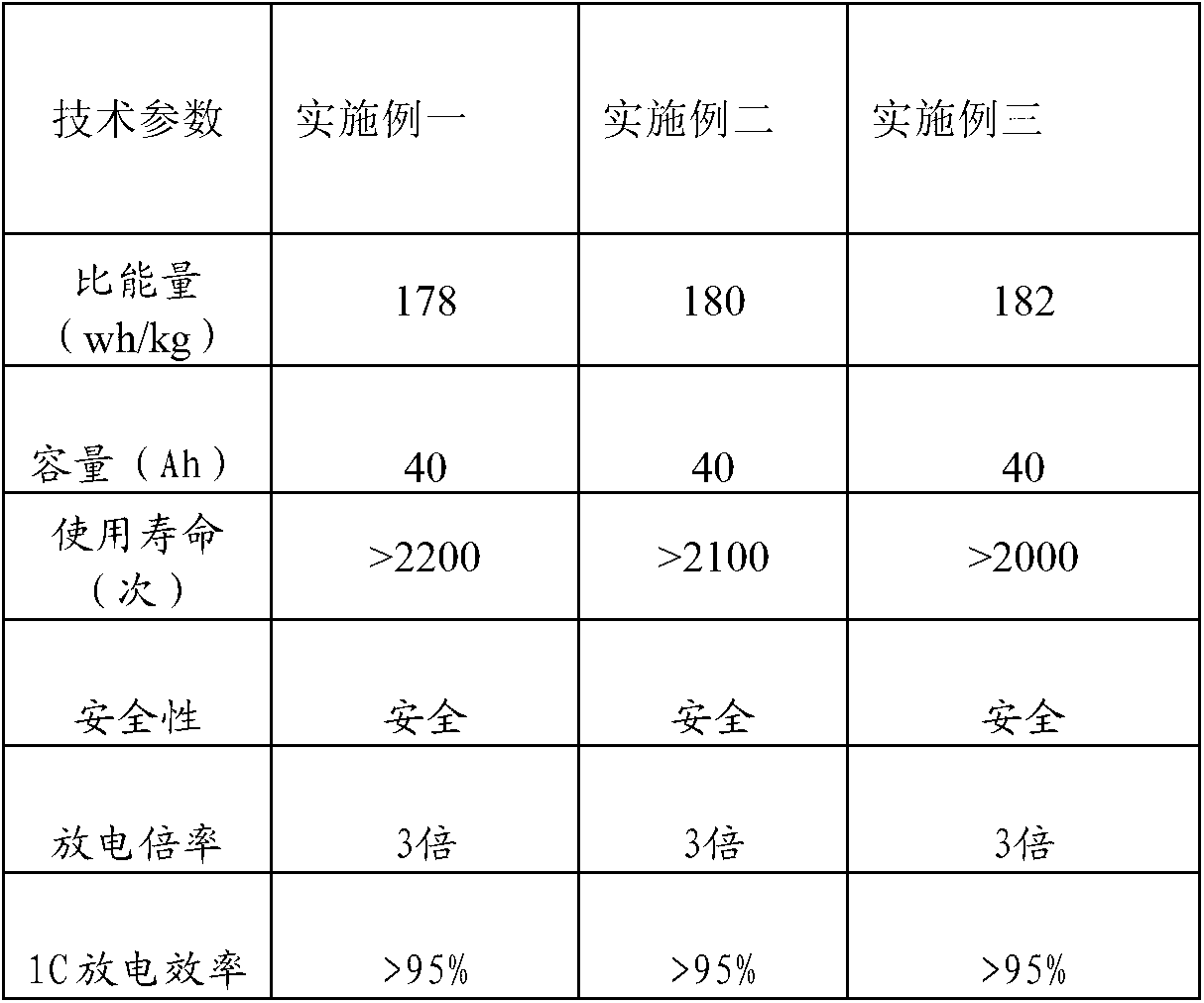

Embodiment 1

[0050] (1) Preparation of slurry: N-methylpyrrolidone is used as a solvent to configure the positive electrode slurry. The materials used in the positive electrode and their weight percentage ratio are: lithium manganate 93%, conductive carbon black 3%, polyvinylidene fluoride 3% %, the balance is the positive current collector, first add polyvinylidene fluoride to N-methylpyrrolidone according to the slurry ratio, and carry out vacuum stirring for 5.5 hours under the condition of circulating water cooling, and then add evenly mixed lithium manganate and the mixture of the conductive agent, after adding the material, stir for 11 hours, and pass the obtained slurry through a 150-mesh sieve once;

[0051]The negative electrode slurry was prepared with deionized water as the medium. The materials used in the negative electrode and their weight percentage ratios were: 89% graphene, 0.5% conductive carbon black, 2% styrene-butadiene rubber, 0.5% sodium carboxymethyl cellulose, and ...

Embodiment 2

[0063] (1) Preparation of slurry: N-methylpyrrolidone is used as a solvent to configure the positive electrode slurry. The materials used in the positive electrode and their weight percentage ratios are: lithium manganate 94%, conductive carbon black 3.5%, polyvinylidene fluoride 3.5% %, the balance is the positive current collector, first add polyvinylidene fluoride to N-methylpyrrolidone according to the slurry ratio, and carry out vacuum stirring for 5.7 hours under the condition of circulating water cooling, and then add evenly mixed lithium manganate and the mixture of conductive agent, after adding the material, stir for 11.5 hours, and pass the obtained slurry through a 150-mesh sieve once;

[0064] The negative electrode slurry was prepared with deionized water as the medium. The materials used in the negative electrode and their weight percentage ratios were: 91% graphene, 1.5% conductive carbon black, 2.5% styrene-butadiene rubber, 1.5% sodium carboxymethyl cellulose,...

Embodiment 3

[0076] (1) Preparation of slurry: N-methylpyrrolidone is used as a solvent to configure the positive electrode slurry. The materials used in the positive electrode and their weight percentage ratios are: lithium manganate 95%, phosphorus flake graphite 1.8%, polyvinylidene fluoride 3.8 %, the balance is the positive current collector, first add polyvinylidene fluoride to N-methylpyrrolidone according to the slurry ratio, and carry out vacuum stirring for 6 hours under the condition of circulating water cooling, and then add evenly mixed lithium manganate and the mixture of conductive agent, add the material and stir for 12 hours, and the obtained slurry is passed through a 150-mesh sieve twice;

[0077] The negative electrode slurry was prepared with deionized water as the medium. The materials used in the negative electrode and their weight percentage ratios were: 92% graphene, 2% conductive carbon black, 2.5% styrene-butadiene rubber, 2% sodium carboxymethyl cellulose, and T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com