Losartan potassium membrane controlled-release pellet capsule

A technology of losartan potassium film and sustained-release pellets, which can be applied to medical preparations of non-active ingredients, cardiovascular system diseases, organic active ingredients, etc., and can solve the problems of membrane aging and release decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The losartan potassium slow-release pellet capsule of embodiment 1 common ball core

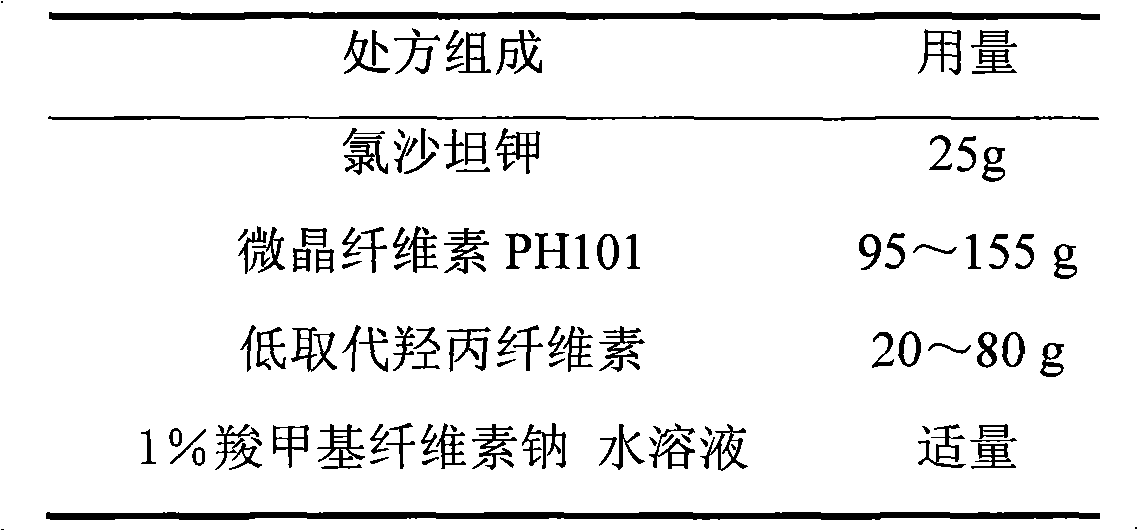

[0029] 1. Prescription

[0030] 1. Pill core prescription (1000 capsules)

[0031]

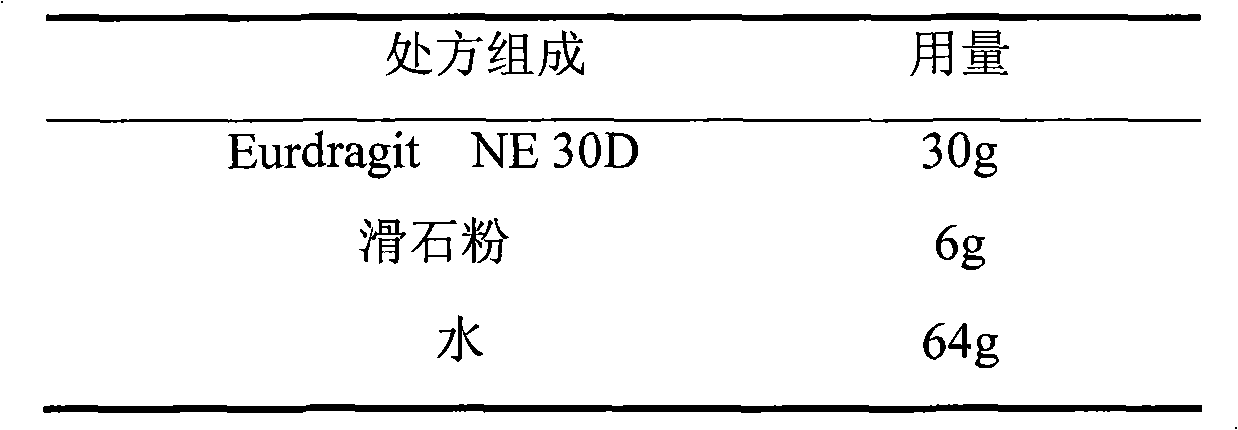

[0032] 2. Prescription of sustained-release film coating solution

[0033]

[0034]

[0035] 3. No. 0 stomach-soluble gelatin capsule shell 1000 capsules

[0036] Second, the preparation process:

[0037] 1. Ball core preparation process:

[0038] (1) Losartan potassium is passed through a 60 mesh sieve;

[0039](2) Losartan Potassium and Microcrystalline Cellulose PH101 are taken by weighing recipe quantity, put in wet granulator and mix homogeneously;

[0040] (3) soft material made of 1% sodium carboxymethyl cellulose aqueous solution;

[0041] (4) Extrude on the extruder, the screen aperture is 1.0mm, and the extrusion speed is 20-30rpm;

[0042] (5) spheronization, the spheronization speed is 900~1000rpm, drying in the fluidized bed;

[0043] (6) Sieve, and take ball cores between...

Embodiment 2

[0069] Example 2 Losartan Potassium Sustained-release Pellet Capsules Containing 10% Low-substituted Hypromellose

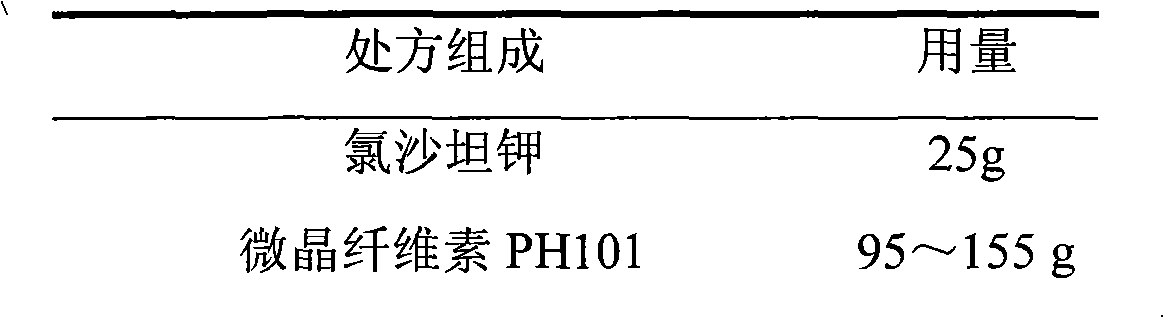

[0070] 1. Prescription

[0071] 1. Pill core prescription (1000 capsules)

[0072]

[0073] 2. Prescription of sustained-release film coating solution: same as in Example 1

[0074] 3. No. 0 stomach-soluble gelatin capsule shell 1000 capsules

[0075] Second, the preparation process:

[0076] 1. Ball core preparation process:

[0077] (1) Losartan potassium is passed through a 60 mesh sieve;

[0078] (2) Losartan Potassium, microcrystalline cellulose PH101, low-substituted hydroxypropyl cellulose are taken by weighing recipe quantity, put in wet granulator and mix homogeneously;

[0079] (3) soft material made of 1% sodium carboxymethyl cellulose aqueous solution;

[0080] (4) Extrude on the extruder, the screen aperture is 1.0mm, and the extrusion speed is 20-30rpm;

[0081] (5) spheronization, the spheronization speed is 900~1000rpm, drying in the flu...

Embodiment 3

[0100] Example 3 Losartan Potassium Sustained-release Pellet Capsules Containing 20% Low-substituted Hypromellose

[0101] 1. Prescription

[0102] 1. Pill core prescription (1000 capsules)

[0103]

[0104] 2. Prescription of sustained-release film coating solution: same as in Example 1

[0105] 3. No. 0 stomach-soluble gelatin capsule shell 1000 capsules

[0106] Second, the preparation process:

[0107] 1. Ball core preparation process: the same as in Example 2

[0108] 2. Preparation process of sustained-release film coating solution:

[0109] Same as Example 1

[0110]3. Coating (sustained release film):

[0111] The ball core is placed in a fluidized bed for coating, and the weight gain of the coating film is controlled, and the weight gain of the coating is 21.3% and 27.5%.

[0112] 4, heat treatment: with embodiment 1

[0113] 5. Fill capsules

[0114] The coated micropills are filled into capsules to obtain losartan potassium sustained-release micropill ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com